High-Pressure Adsorption of Supercritical Carbon Dioxide using an MSB-Magnetic Suspension Balance

Download PDF

- Research Background

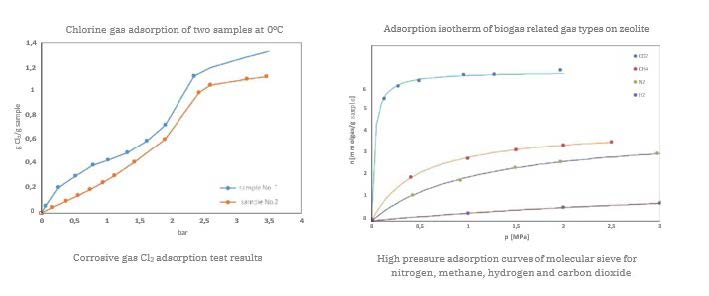

Carbon dioxide (CO₂) is a major greenhouse gas, and technologies for its capture and storage are central to combating climate change. Among the available approaches, adsorption using porous materials has gained significant traction due to its low energy demands and high efficiency. However, conventional CO₂ adsorption at ambient conditions suffers from low capacity and poor selectivity.

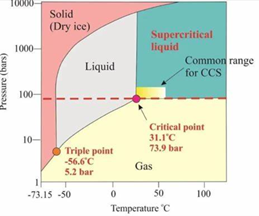

Supercritical CO₂ (scCO₂)—formed when CO₂ surpasses its critical point of 31.1°C and 7.39 MPa—exhibits a hybrid of gas and liquid properties: high diffusivity, tunable density, and low viscosity. These attributes make it uniquely useful in materials science, separation, and enhanced oil recovery (EOR).

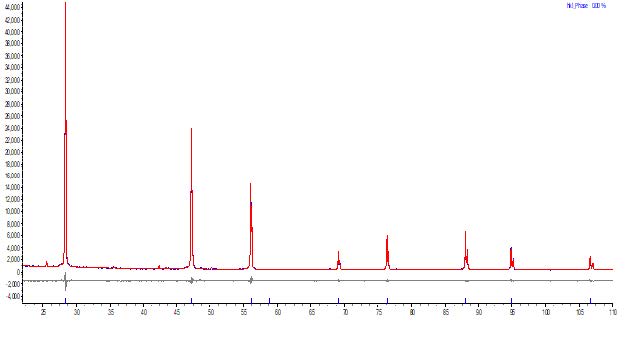

FIGURE 1 – Phase Diagram of Supercritical CO₂

Geological Sequestration

scCO₂ geological sequestration is a widely recognized method for long-term CO₂ storage. Injecting scCO₂ into deep geological formations—such as depleted reservoirs and saline aquifers—allows CO₂ to be trapped through structural, solubility, or residual mechanisms. Mineral carbonation reactions further convert CO₂ into stable carbonate solids, significantly reducing the risk of leakage [1].

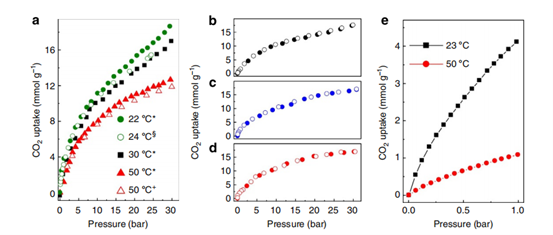

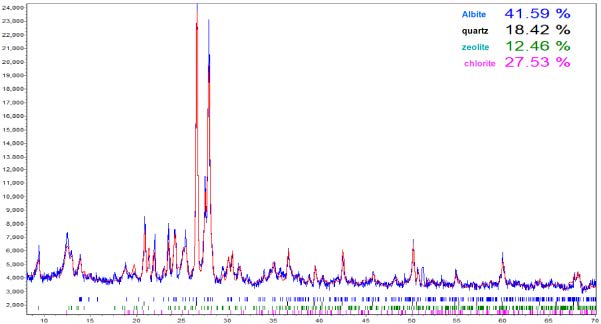

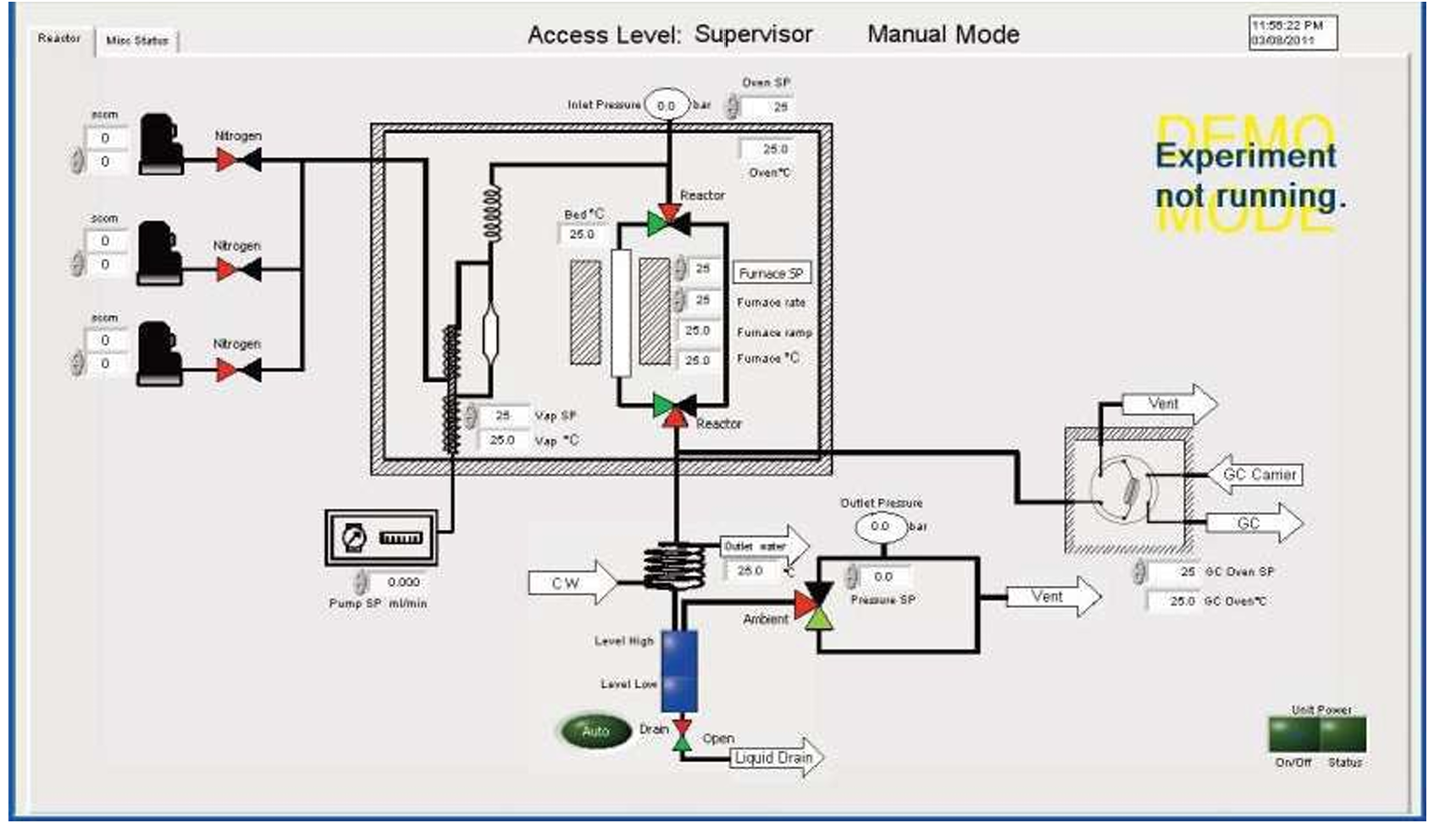

FIGURE 2– Investigation of CO₂ Adsorption under Normal vs. High Pressure

Enhanced Oil Recovery (CO₂-EOR)

EOR using scCO₂ serves both economic and environmental goals. When scCO₂ reaches miscibility pressure with crude oil (typically >10 MPa), it significantly reduces oil viscosity and improves flow characteristics.

EOR injection methods include:

- Continuous injection

- Water-Alternating-Gas (WAG)

scCO₂-EOR can increase recovery by 10–25% and extend oil field lifetimes by decades. In the U.S., such projects already sequester 30 million tons of CO₂ annually, or 1.5% of industrial emissions.

- Gravimetric Method for scCO₂ Adsorption

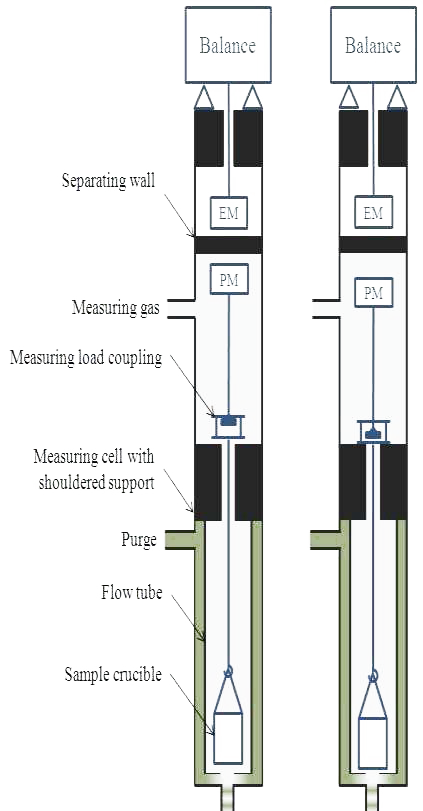

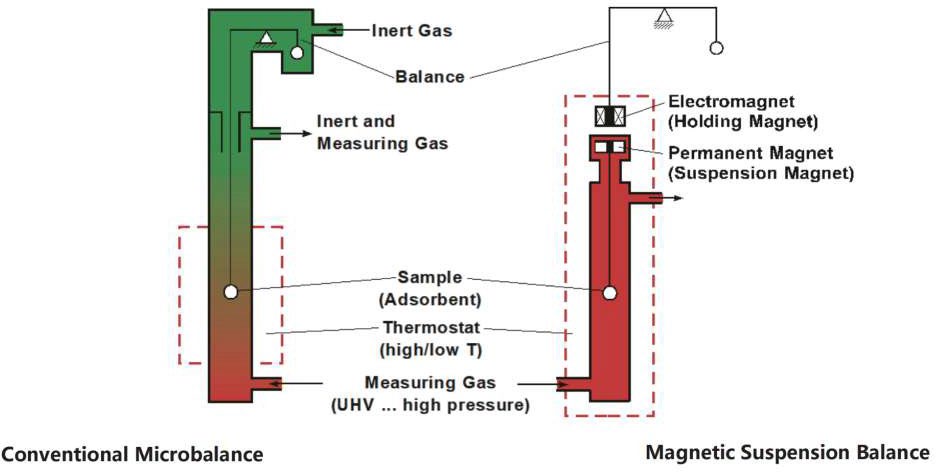

2.1 Why Magnetic Levitation?

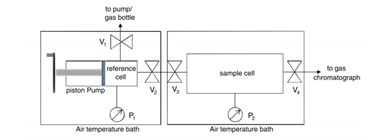

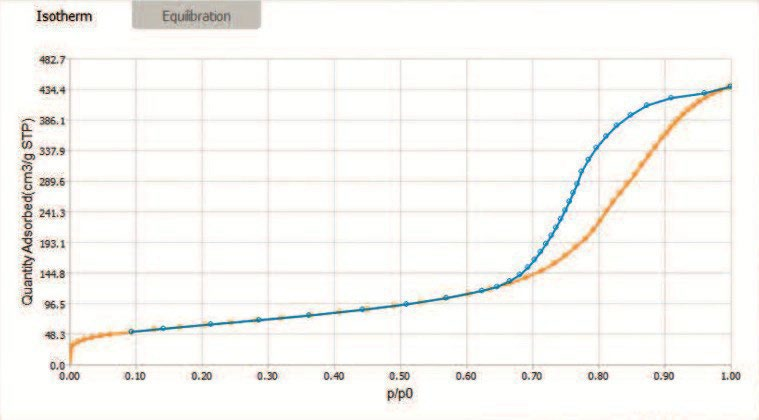

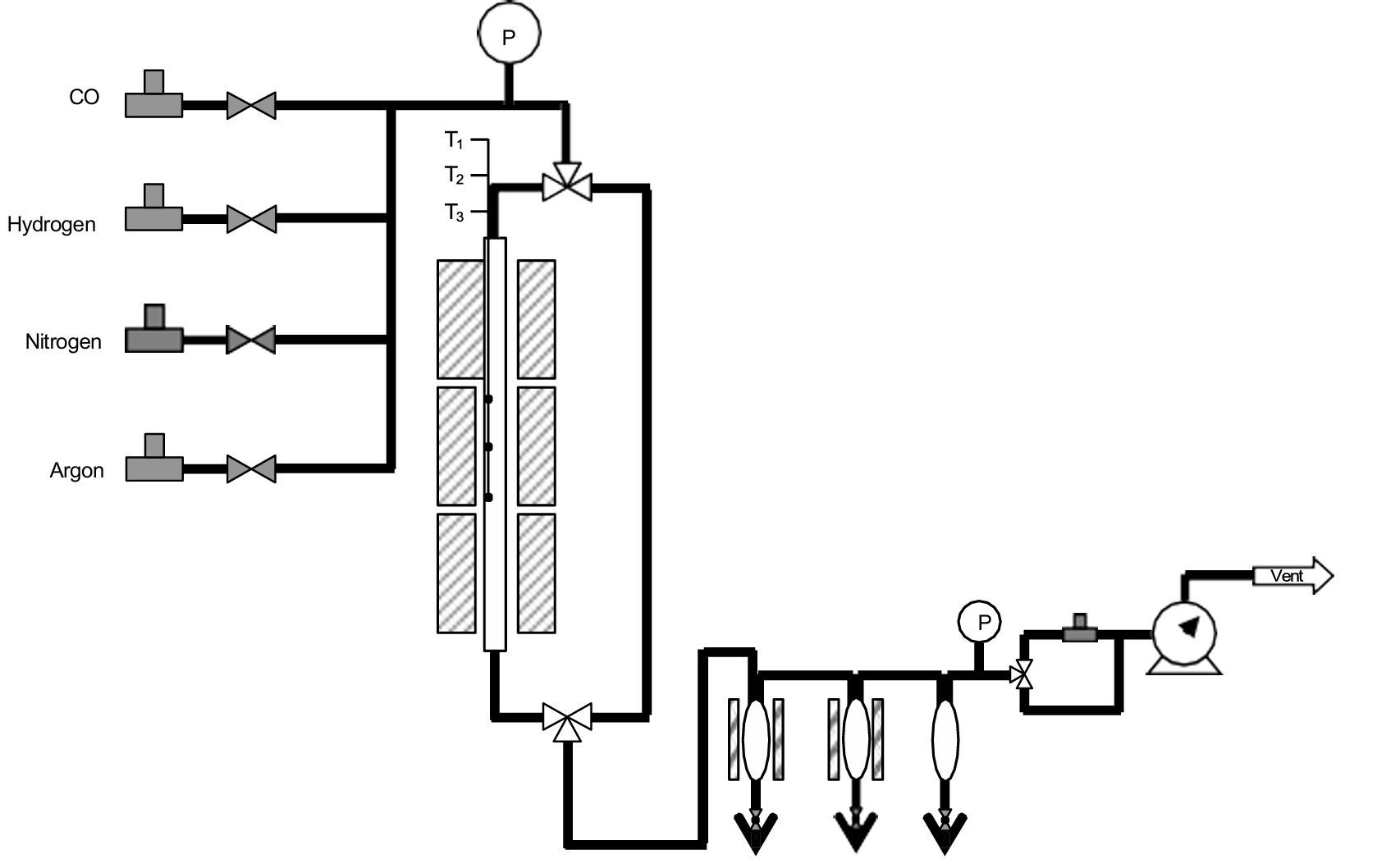

Volumetric methods—though simple—require larger sample quantities and cannot effectively resolve kinetic behavior or low-pressure responses [2].

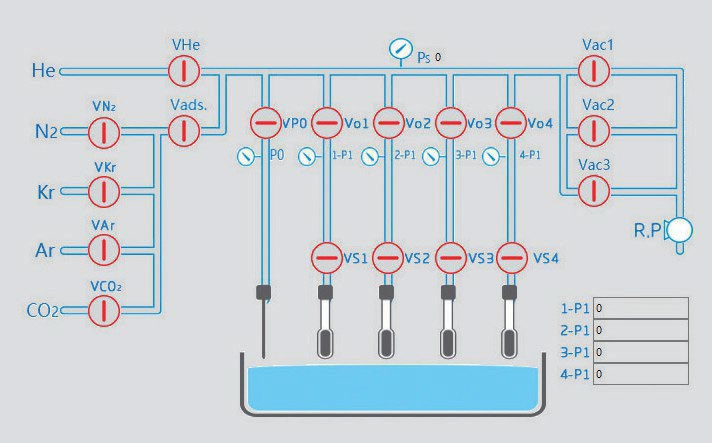

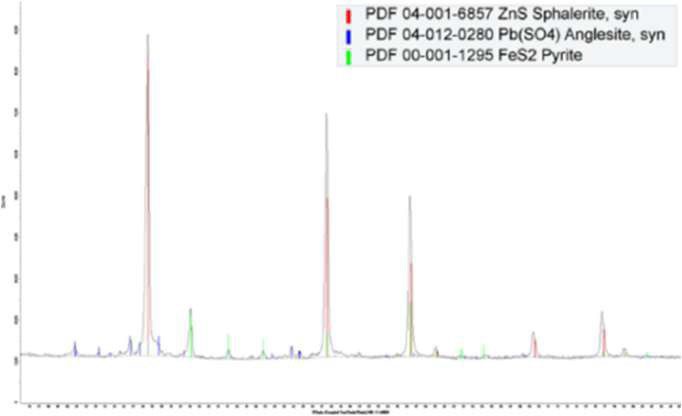

FIGURE 3 – Principle of Volumetric scCO₂ Testing

Gravimetric methods are preferred for high-precision adsorption work, but traditional balances suffer from:

- Buoyancy effects (especially with large samples)

- Balance drift

- Inability to operate in extreme environments

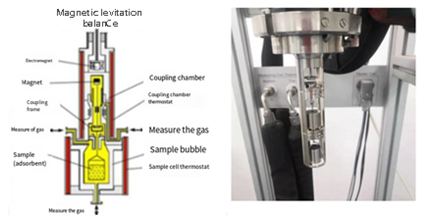

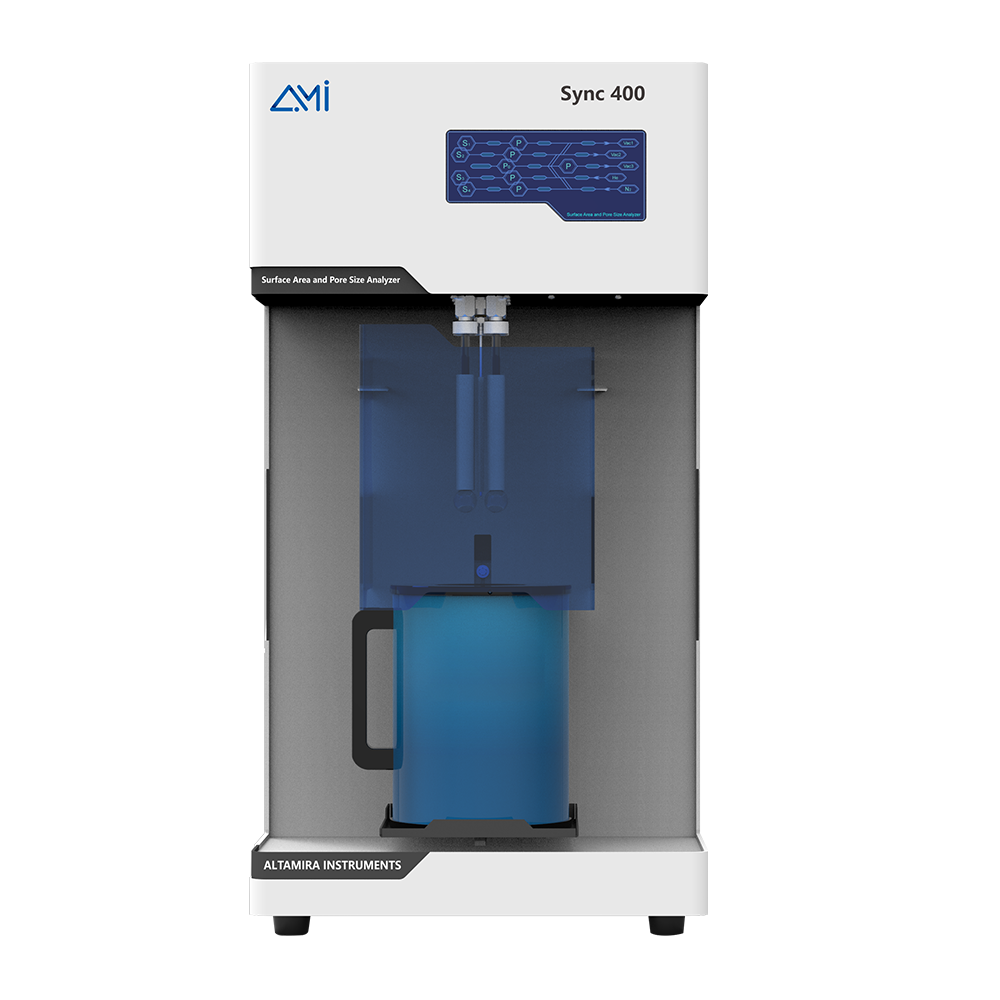

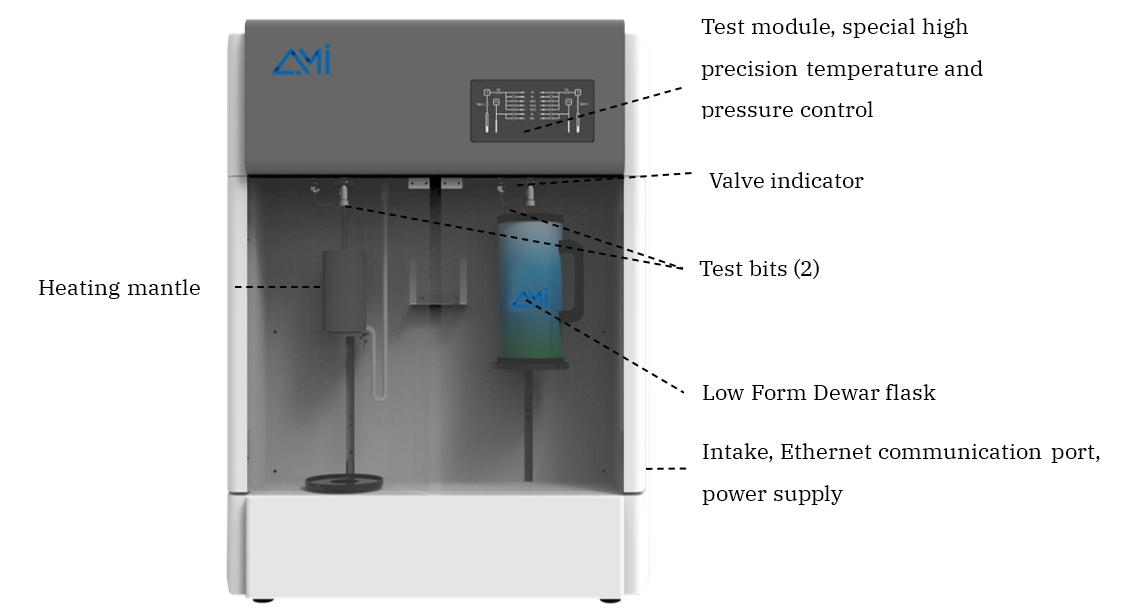

AMI’s Magnetic Suspension Balance (MSB) overcomes these issues:

- Operates under extreme temperatures and pressures

- Transfers weight via non-contact magnetic coupling

- Eliminates drift through periodic position switching

- Corrects buoyancy using reference masses or known fluid densities.

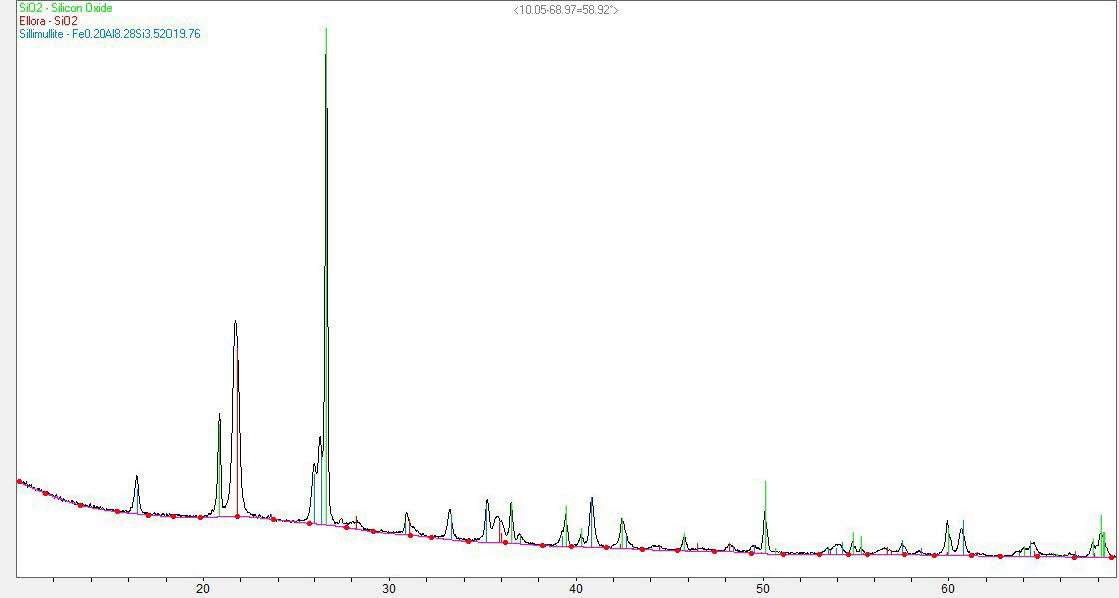

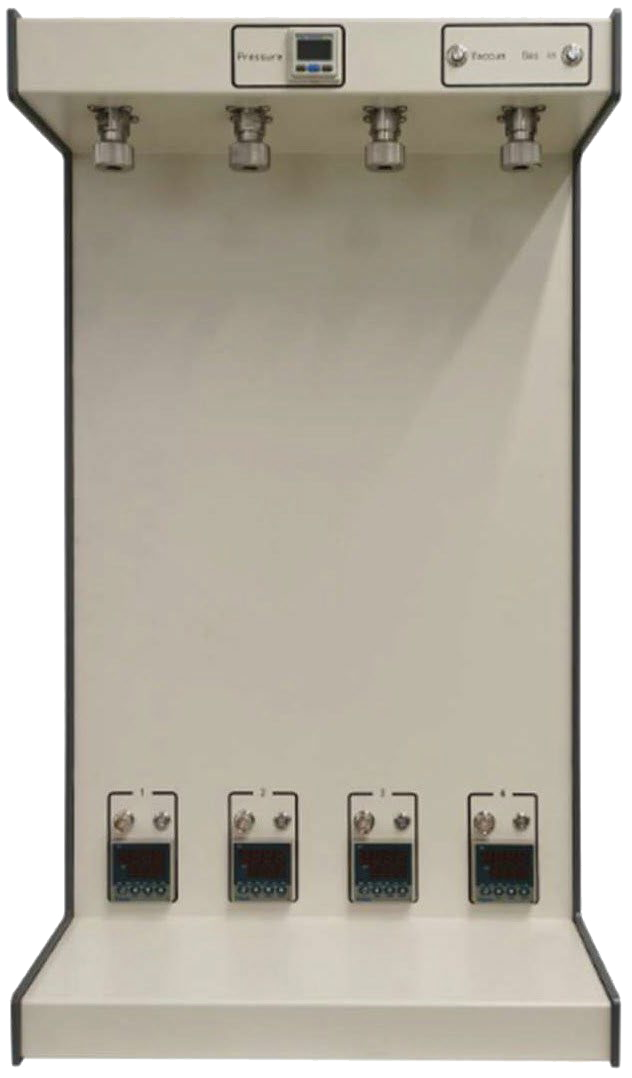

FIGURE 4 – Magnetic Levitation Instrument Structure

- Application Cases

Case 1: Supercritical CO₂ Adsorption in Coal

High-pressure, high-temperature coal seams are ideal for CO₂ sequestration. Li and Ni et al. investigated the CO₂ adsorption behavior of Tunliu and Sihe coal under supercritical conditions [3].

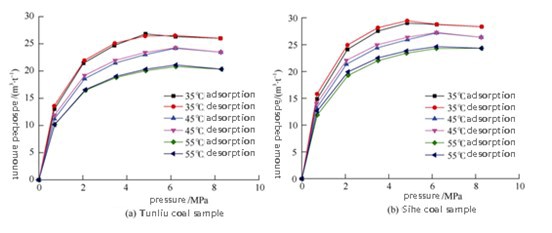

FIGURE 5 – Isothermal Adsorption/Desorption Curves of Two Coal Types

Key Observations:

- Adsorption capacity peaks then declines

- Higher temperature = lower capacity

- Sihe coal has greater uptake than Tunliu

- Behavior follows Type I (IUPAC) isotherms before saturation [4]

However, corrections for excess vs. absolute adsorption and phase density assumptions are required to obtain true capacity data. Post-correction, adsorption shows stable increase with pressure and fully reversible desorption.

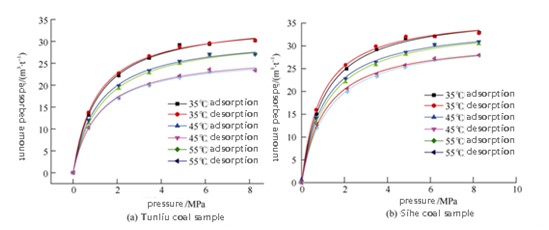

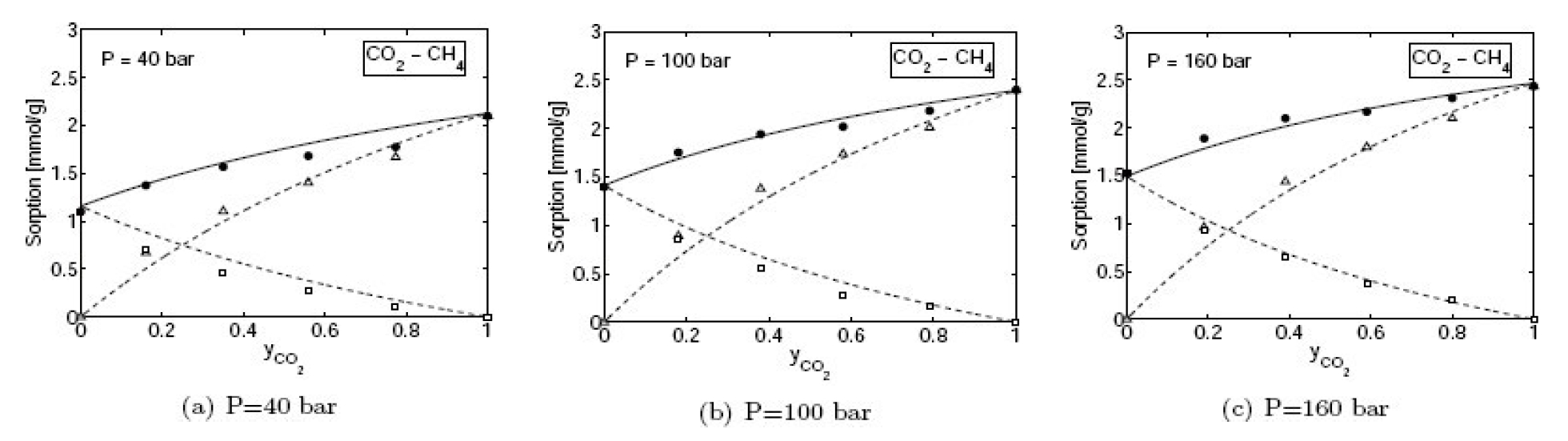

FIGURE 6– Density-Corrected Isotherms with Binary Langmuir Fitting

Case 2: Kinetics of scCO₂ Adsorption

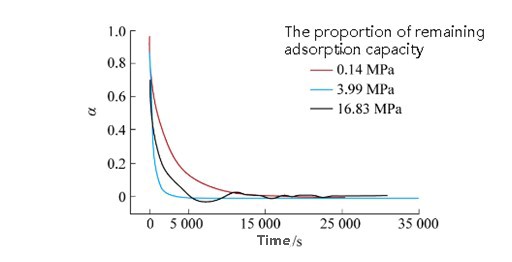

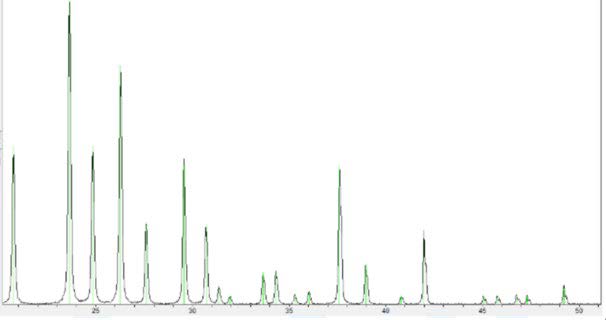

Monitoring real-time uptake at fixed pressure provides kinetic insight. Adsorption is faster at higher pressure, but at supercritical pressures, adsorption approaches saturation more rapidly, reducing the number of available sites over time [5].

Studies by Charrière and Song show that:

- Residual adsorption capacity declines with time

- Fluctuations at high pressure are caused by density shifts near critical conditions [6][7]

FIGURE 7– CO₂ Residual Adsorption vs. Time at Various Pressures

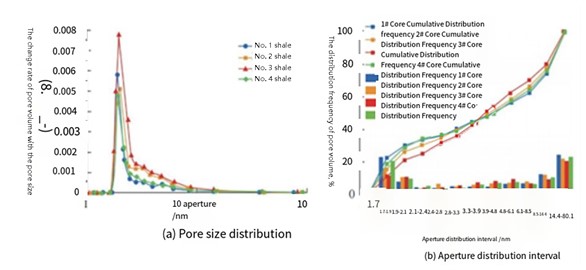

Case 3: CO₂-EOR in Shale Reservoirs

Due to the complexity of core testing in shale (tight pore networks), magnetic levitation offers a direct and non-invasive method to monitor oil extraction.

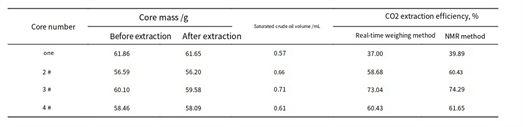

Li and Chen used MSB readings at fixed intervals and compared results to NMR, showing strong correlation [8].

Table 1 – Comparison of Extraction Efficiency by Magnetic Levitation vs. NMR

With increasing CO₂ pressure:

- Smaller pore throats are accessed

- Extraction efficiency improves sharply until minimum miscibility pressure is reached

FIGURE 8– Pore Size Distribution of Tested Samples

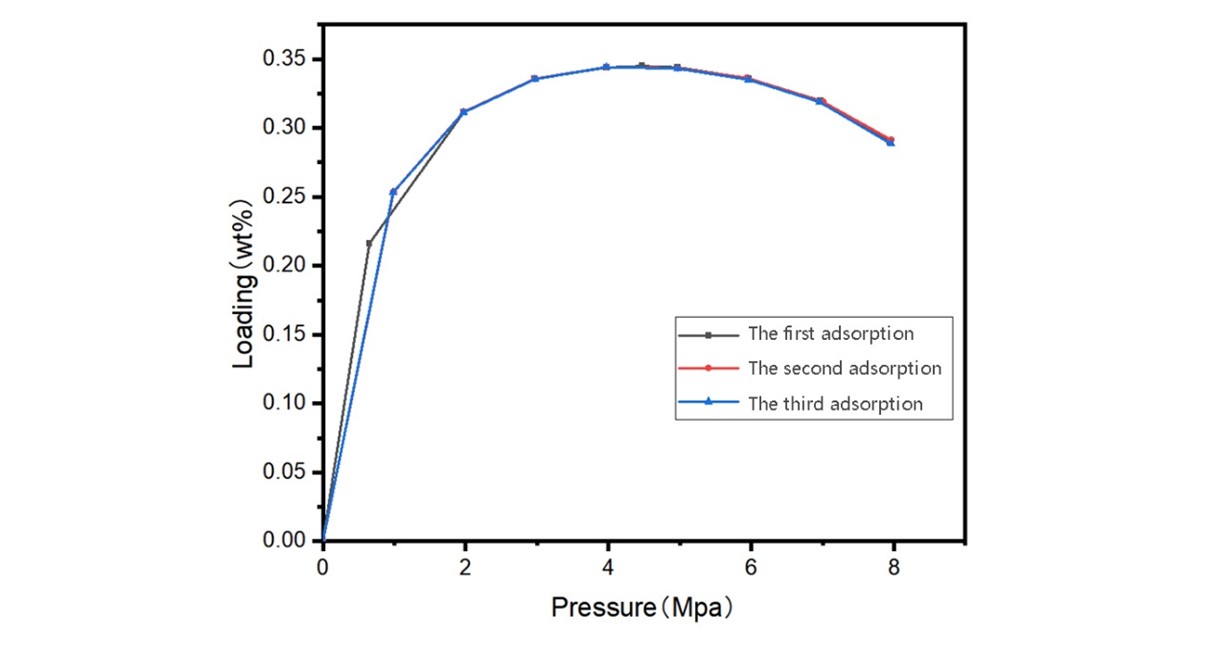

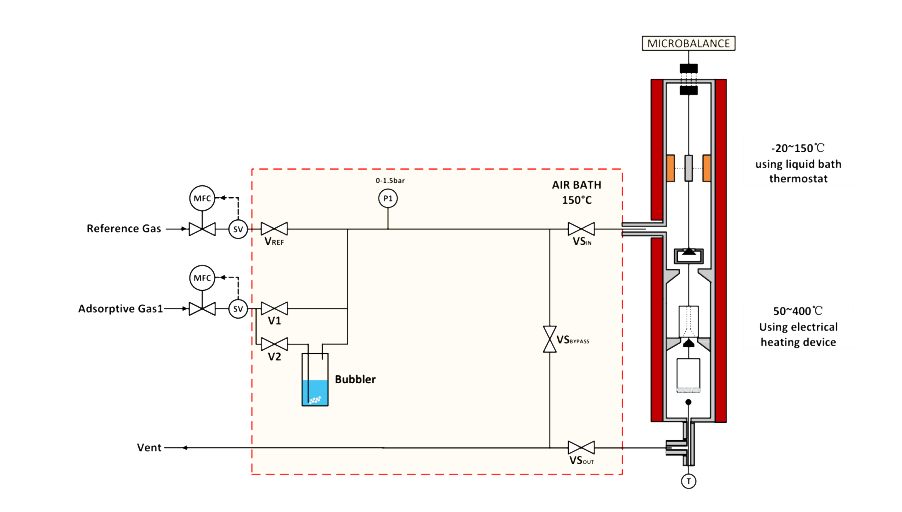

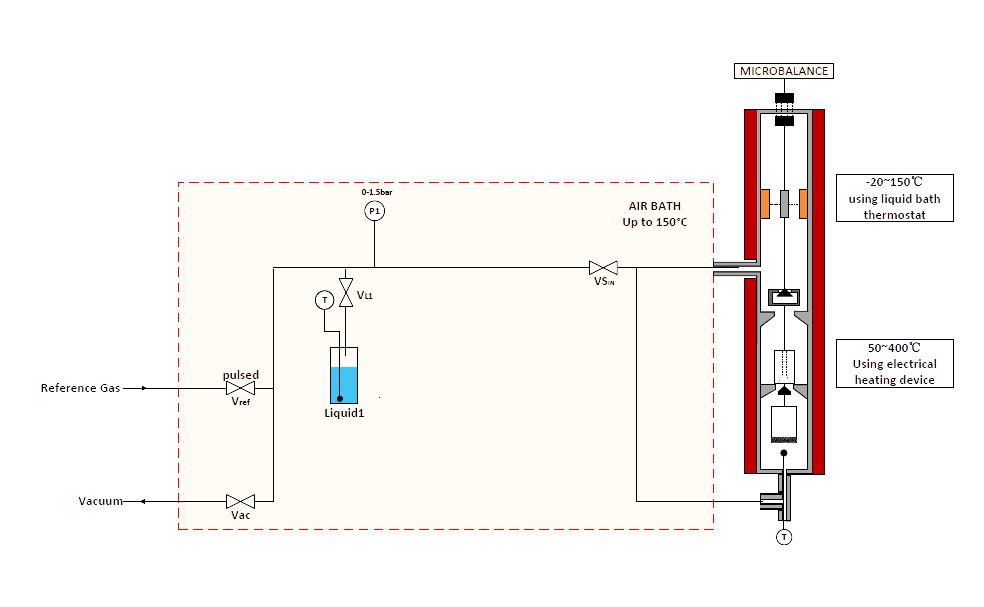

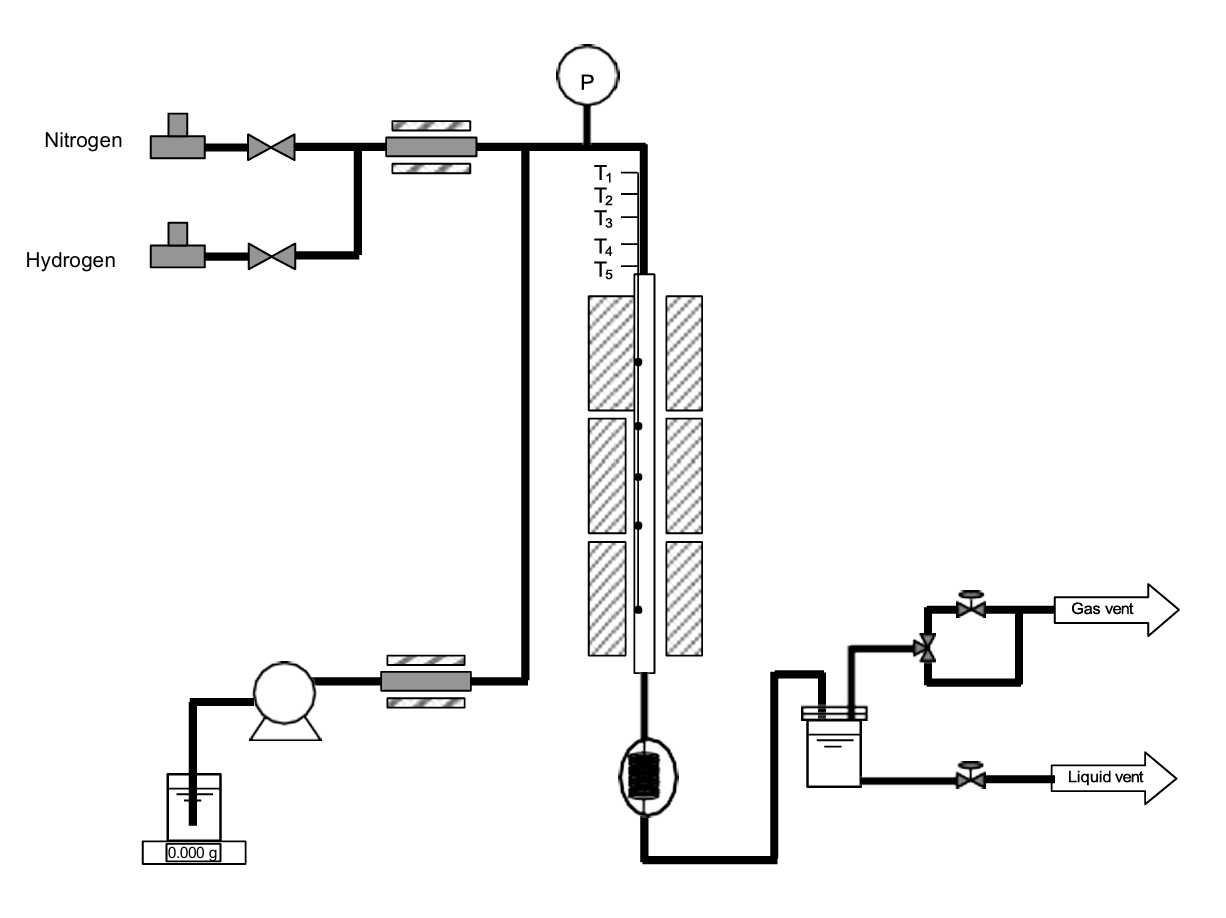

- Experimental Validation

4.1 Conditions

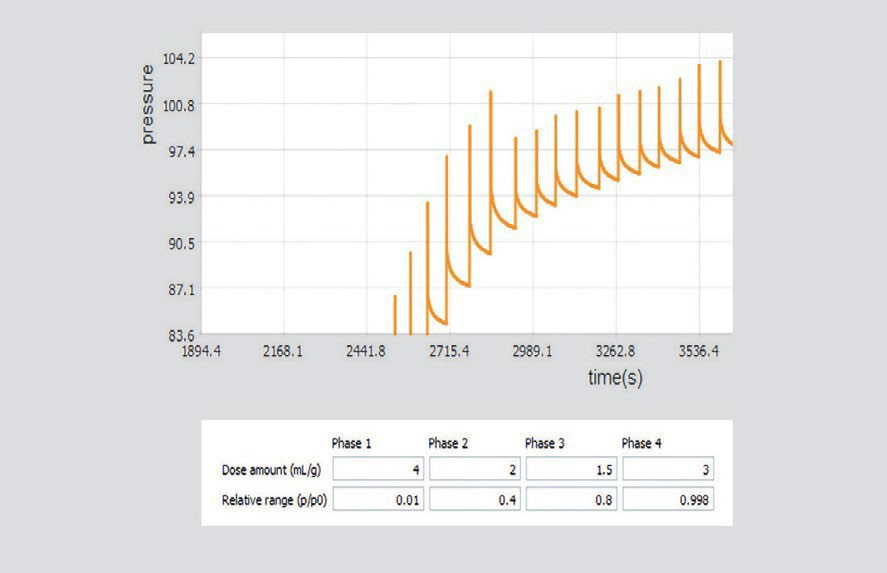

- Instrument: AMI Magnetic Suspension Balance

- Calibration: Helium for volume and mass

- Adsorbate: CO₂ up to 8 MPa

- Temperature: 50°C

- Sample Pretreatment: 200°C for 4 hours

4.2 Results

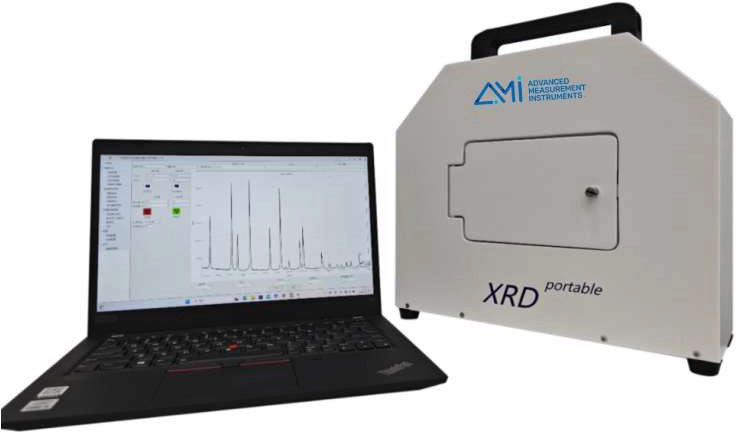

- Adsorption peaked between 40–50 bar

- Maximum uptake: 34.4%

- Minimal deviation between repeated tests

- Long equilibration times observed due to larger sample size

- Recommended: narrow pressure steps for smooth isotherms

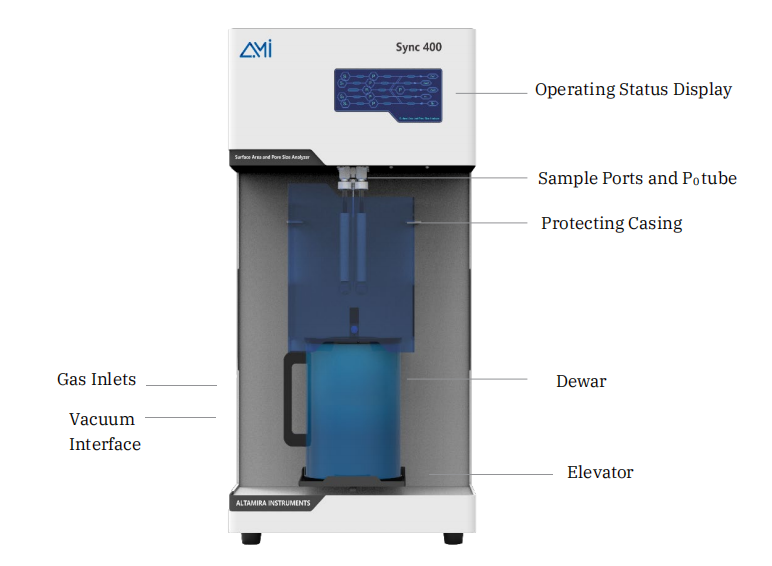

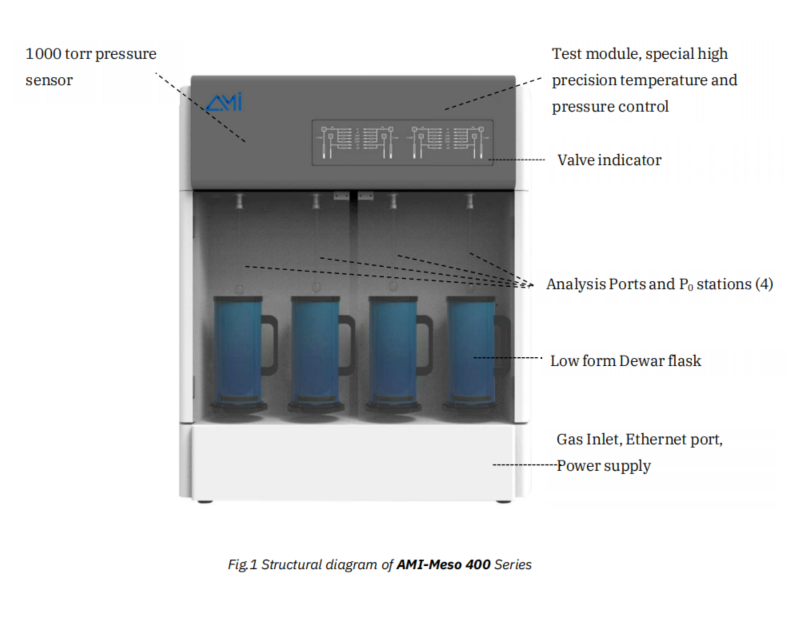

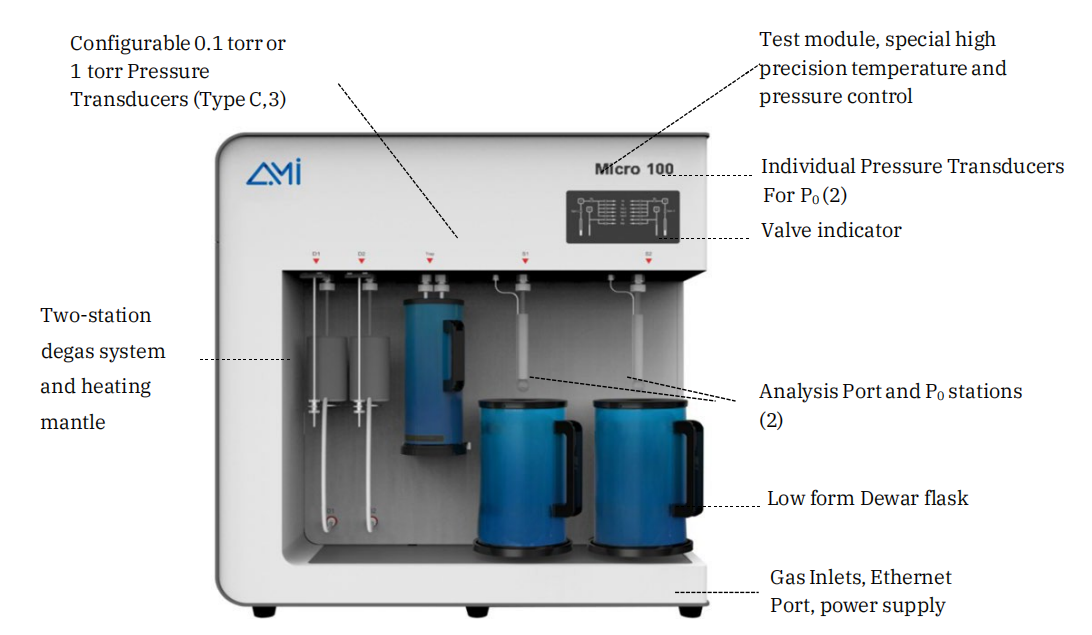

BET analysis showed (on AMI Instruments):

- Surface Area: 1789 m²/g

- Micropore Volume: 0.6 cm³/g

FIGURE 9 – Measured Supercritical CO₂ Adsorption Capacity

- Summary

Magnetic suspension gravimetric systems are essential tools for modern supercritical CO₂ adsorption research. Their advantages include:

- High-pressure and temperature compatibility

- Automatic elimination of drift via dual-position calibration

- In-situ kinetic and isotherm measurements

- Real-time buoyancy correction

Looking forward, future research should address:

- Internal density gradients and convective turbulence

- Adsorbent expansion corrections under extreme conditions

References

[1] Lv, Y., Tang, D., Xu, H., et al. CO₂ sequestration technology for improving coalbed methane recovery. Environmental Science and Technology, 2011, 34(5): 95–99.

[2] Sudibandriyo M., Pan Z., Fitzgerald J.E., et al. Langmuir, 2003, 19: 5323–5331.

[3] Li, Q., Ni, X., Wang, Y., et al. Coalfield Geology and Exploration, 2014, 42(3): 36–40.

[4] Fu, X., Qin, Y., Wei, C. Coalbed Methane Geology, China University of Mining and Technology Press, 2007.

[5] Charrière D., Pokryszka Z., Behra P. International Journal of Coal Geology, 2010, 81(4): 373–380.

[6] Song Y., Xing W., Zhang Y., et al. Adsorption, 2015, 21(1/2): 53–65.

[7] Siemons N., Wolf K.A.A., Bruining J. International Journal of Coal Geology, 2007, 72(3): 315–324.

[8] Li, B., Hou, J., Lei, Z., et al. Petroleum Drilling Technology, 2024, 52(4): 94–103.

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com