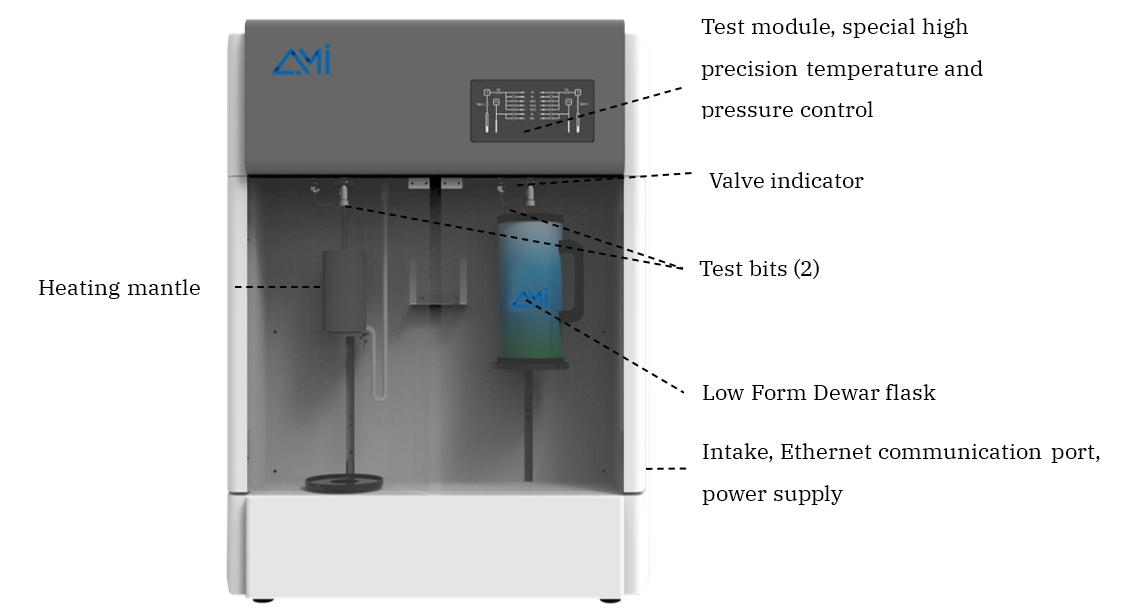

- The AMI-Meso112/222 Series is engineered for high-precision surface area and pore size characterization of powdered materials. This series comprises two models, Meso 112 and Meso 222, both integrated with 1000 torr pressure transducers at each analysis station for accurate BET surface area determination and mesopore size distribution analysis.

- Each analysis port is equipped with an in-situ degassing module capable of heating samples up to 400°C, ensuring efficient removal of adsorbed contaminants prior to analysis. This in-situ degassing eliminates the risk of contamination associated with sample transfer. Additionally, when multiple stations are utilized, each operates independently, allowing for simultaneous yet discrete analyses of different samples.

Advanced Measurement Instruments

Copyright © 2025 Advanced Measurement Instruments

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com