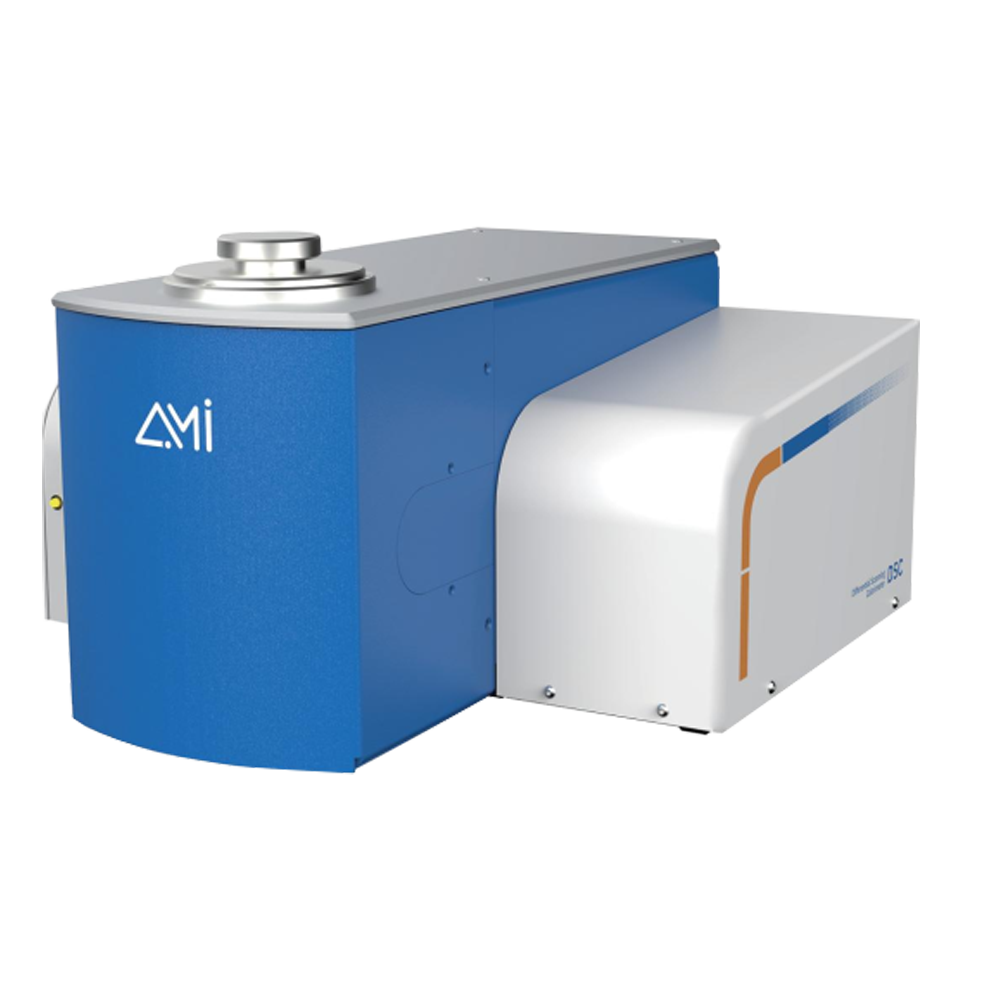

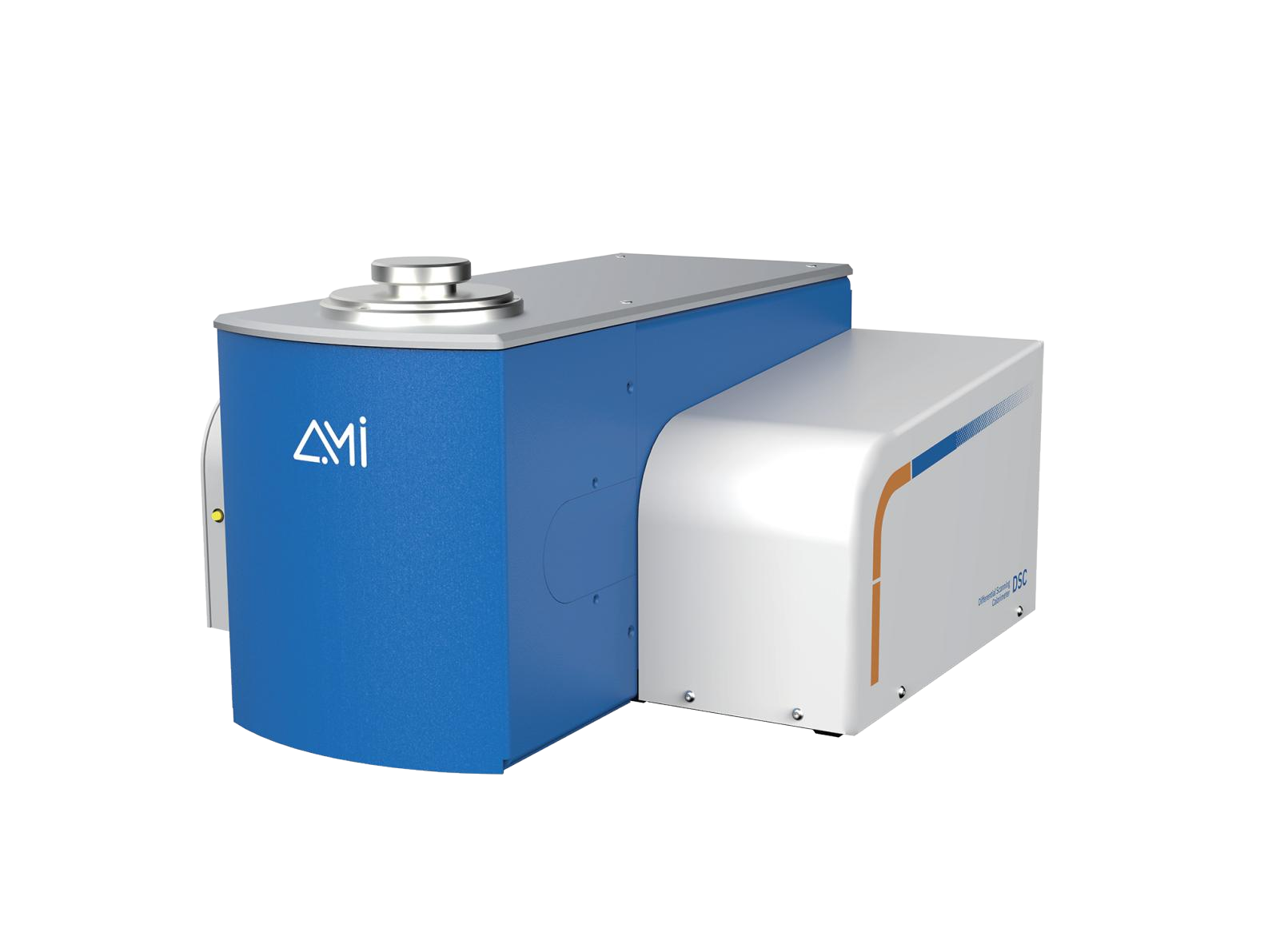

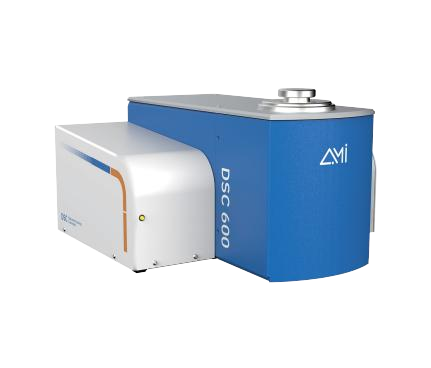

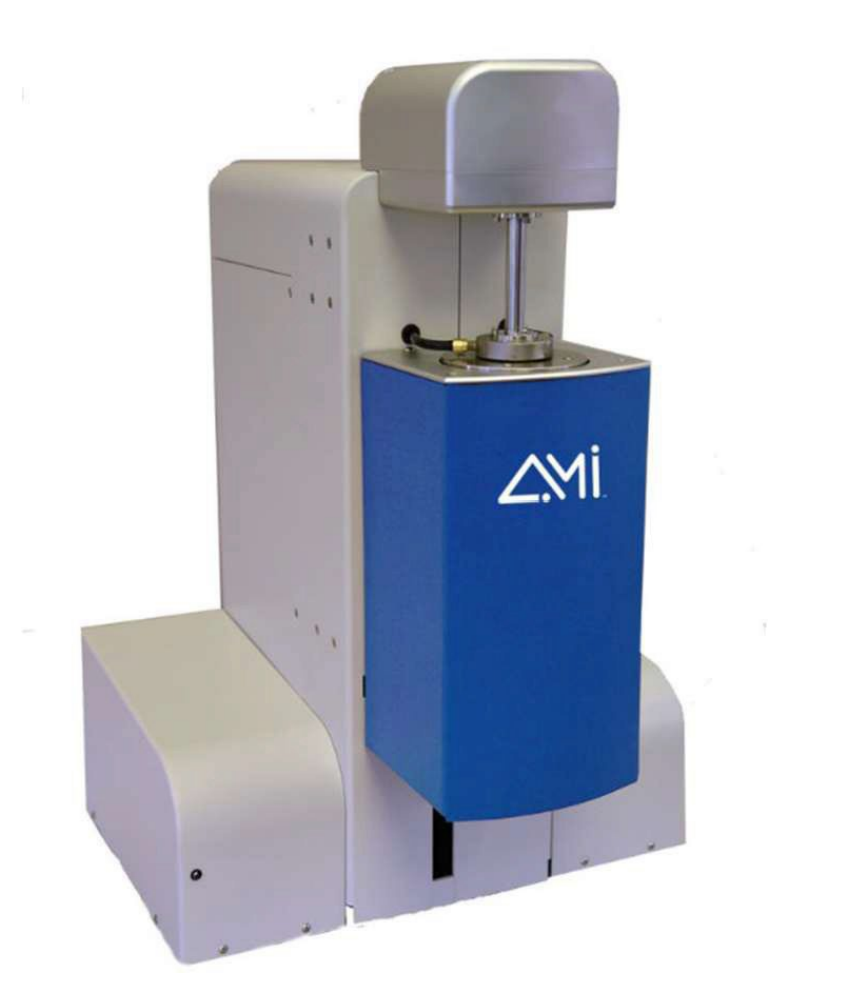

DSC 600

INTRODUCTION

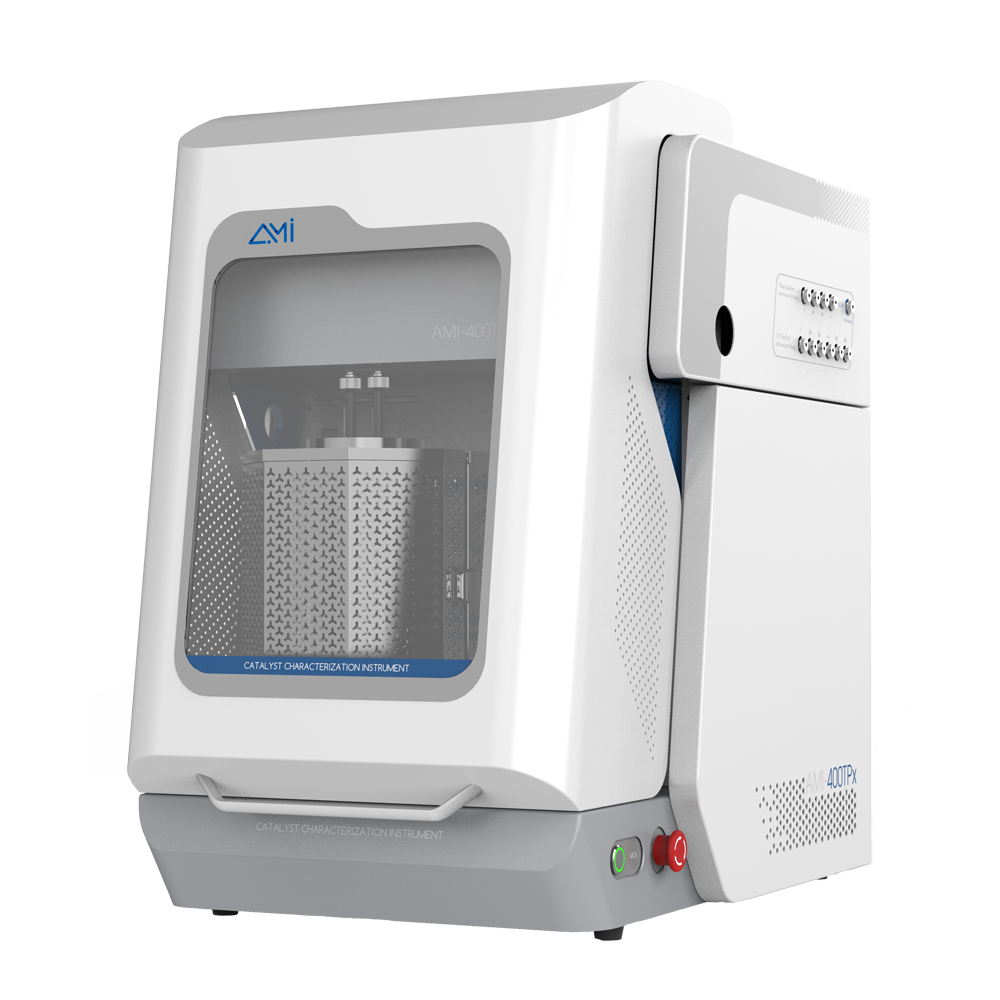

- The DSC 600 from Advanced Measurement Instruments (AMI) is the next generation of Differential Scanning Calorimeters (DSC), crafted to meet the evolving needs of professionals in materials research, chemical engineering, quality control, petrochemicals, and pharmaceuticals. Designed for precision, reliability, and affordability, the DSC 600 sets new standards in thermal analysis.

- At the heart of the DSC 600 is its innovative heat flux plate, engineered to capture the smallest energy changes with unmatched sensitivity and accuracy. This powerful capability enables precise measurements across a broad spectrum of applications, including enthalpy, glass transition, heat of crystallization, purity determination, and heat capacity.

- Equipped with an ultra-light furnace, the DSC 600 ensures excellent thermal conductivity and stability, delivering consistent performance across a wide temperature range. With a selection of specialized heat flux plates, it can be tailored to meet diverse testing needs,enhancing efficiency and flexibility in every lab.

- Typical Applications

- Melting Temperature

- Crystallization Temperature

- Heat of Chemical Reaction

- Glass Transition Temperature

- Specific Heat Capacity

- Degree of Crystallinity

- Degree of Cure

- Oxidative Stability

- Thermal Stability

- Solid-State Phase Transition

- Liquid Crystal Phase Transition

- Aging of Materials

- Polymorph

- DSC 600

FEATURES

- Precision

- High-sensitivity heat flow sensor platform delivers calorimetric accuracy of ±0.1%. With four distinct heat flow sensor types available, it comprehensively meets the precise measurement needs of diverse materials, accommodating a wide range of experimental and application scenarios.

- Featuring innovative furnace technology and unique sensor design, the system achieves exceptional baseline repeatability while offering low noise, high sensitivity, and outstanding resolution. This ensures the detection of even minute thermal changes that might otherwise be lost in noise.

- Stability

- The mineral-insulated furnace body design combines excellent thermal conductivity with corrosion resistance, while dual-PID temperature control ensures data accuracy and stability.

- Advanced circumferential heating technology and a proprietary dual-PID control system guarantee precise adherence to programmed temperature profiles during both heating and cooling phases. With temperature control accuracy of ±0.01°C, the system significantly minimizes thermal fluctuations that could compromise experimental results.

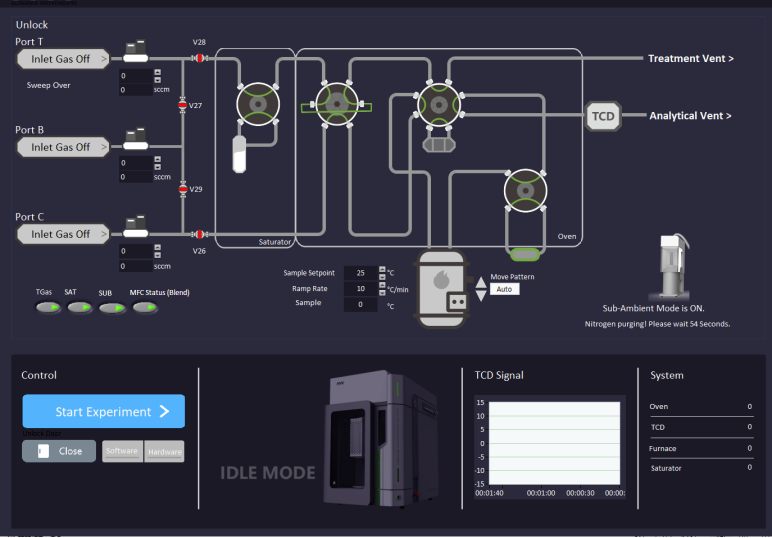

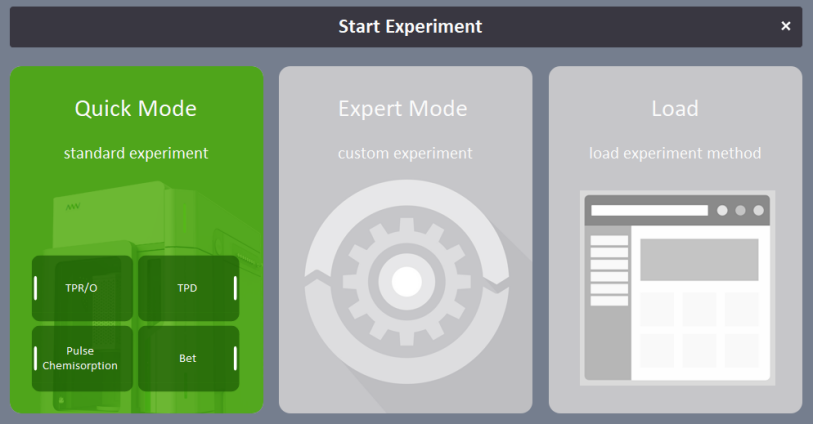

- Ease of Use

- The intuitive software interface features streamlined UI and modular architecture, enabling effortless operation. Researchers can quickly master experimental setup, data analysis, and all critical workflows.

- The maintenance optimized furnace design allows easy cleaning even after sample contamination during loading, significantly enhancing experimental efficiency while extending equipment service life.

- High-Precision Heat Flow Sensor

- The self-developed high-sensitivity heat flow sensor platform delivers low noise, high sensitivity, and exceptional resolution to reliably detect minute thermal variations that might otherwise be obscured by noise.

- Four Types of Heat Flow Sensors

- The DSC600 offers four types of heat flow sensor platforms: standard testing type, high-sensitivity type (for biopharmaceutical materials), corrosion-resistant type (for corrosive samples), and energetic materials type (for chemical reactions). These sensors meet the requirements of different application scenarios and sample types.

- Precision Temperature Control

- The system utilizes circumferential heating technology and a proprietary dual-PID control system to ensure exact adherence to programmed temperature curves during heating/cooling processes. With a temperature control accuracy of ±0.01°C, it effectively minimizes thermal fluctuations that could compromise experimental results.

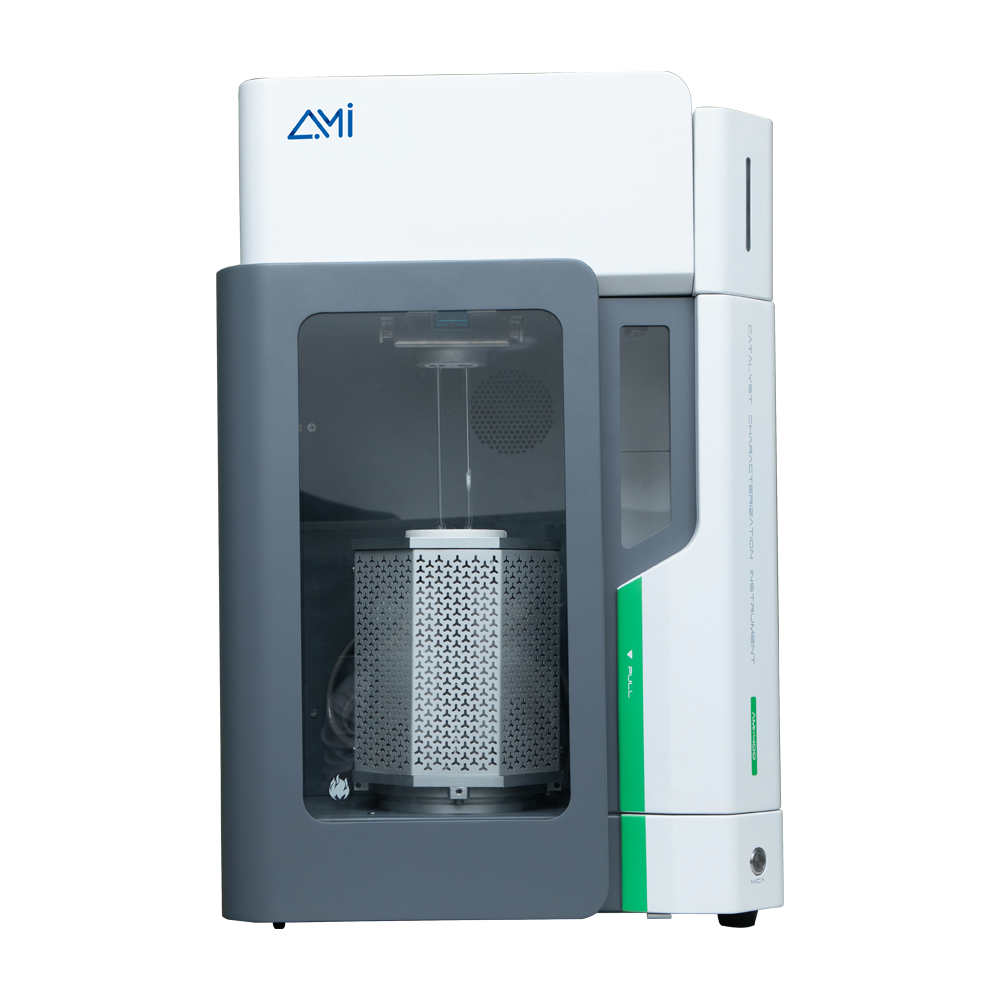

- Ultralight Mineral Furnace

- The silver-constructed furnace body delivers exceptional thermal conductivity and stability, ensuring precise temperature control and rapid thermal response. The pure silver material effectively minimizes heat loss while enhancing analytical efficiency, achieving uniform heating/cooling across samples. Its superior corrosion resistance extends instrument service life, accommodating diverse experimental environments.

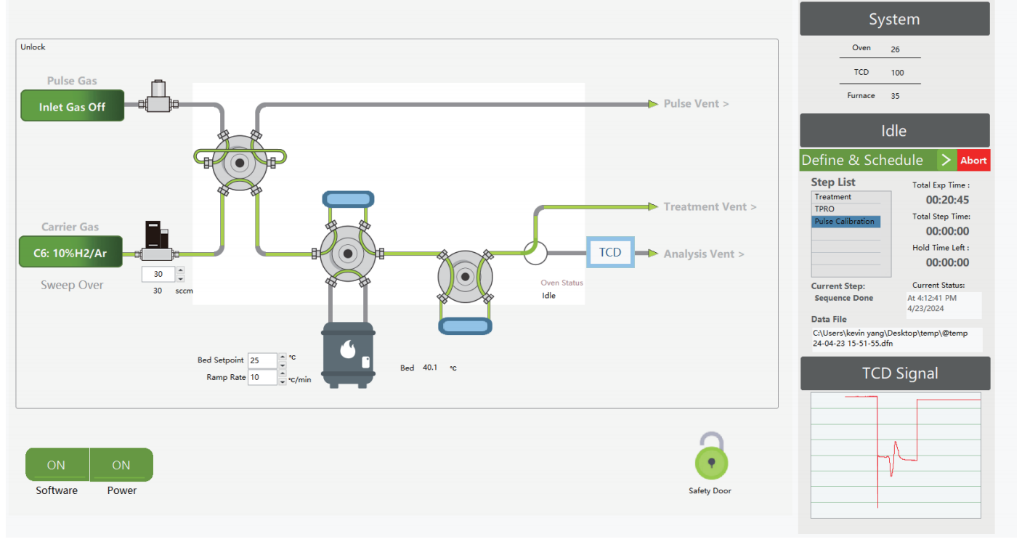

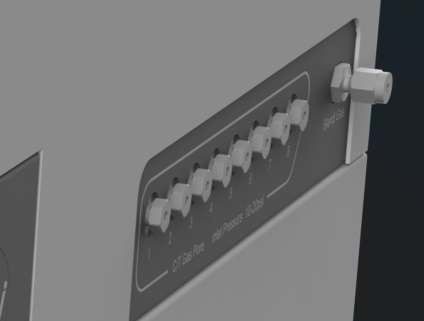

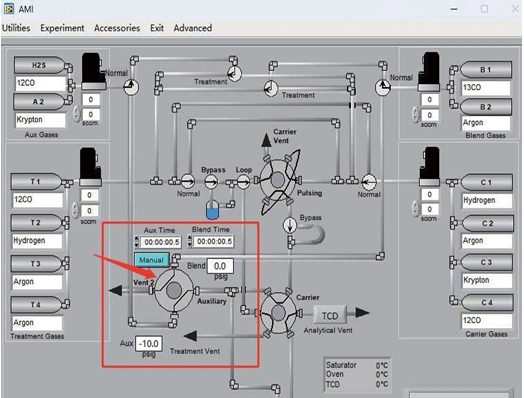

- Automatic Gas Switching Control

- The multi-channel gas inlet device enables automatic gas switching during experiments. This integrated unit combines four or six gas lines into a single module to meet the demands of frequent gas changes across different testing procedures.

- Gas Preheating Function

- The furnace incorporates heated gas lines at the inlet ports, enabling gas preheating before entering the sample chamber. This design stabilizes experimental conditions and enhances testing efficiency.

-

- Three High-Efficiency Cooling Systems

- The DSC 600 is equipped with three high-efficiency cooling systems, offering versatile refrigeration options: water bath cooling, mechanical refrigeration, and liquid nitrogen cooling.

- The water bath cooling system regulates furnace temperatures from 10°C to 600°C, ideal for scenarios not requiring cryogenic conditions, such as polymer melting point and crystallization temperature analysis. The mechanical refrigeration system covers a temperature range of -90°C to 450°C, widely used in polymer material analysis, including glass transition studies, crystallization kinetics research, and conventional low-temperature testing applications.

- The liquid nitrogen cooling system utilizes the endothermic properties of evaporating liquid nitrogen for rapid cooling, with a furnace temperature range of -150°C to 600°C. It is primarily employed for ultra-low temperature research, such as metal alloy phase transitions, superconducting material analysis, and rapid quenching experiments, including amorphous material preparation and fast cooling process studies.

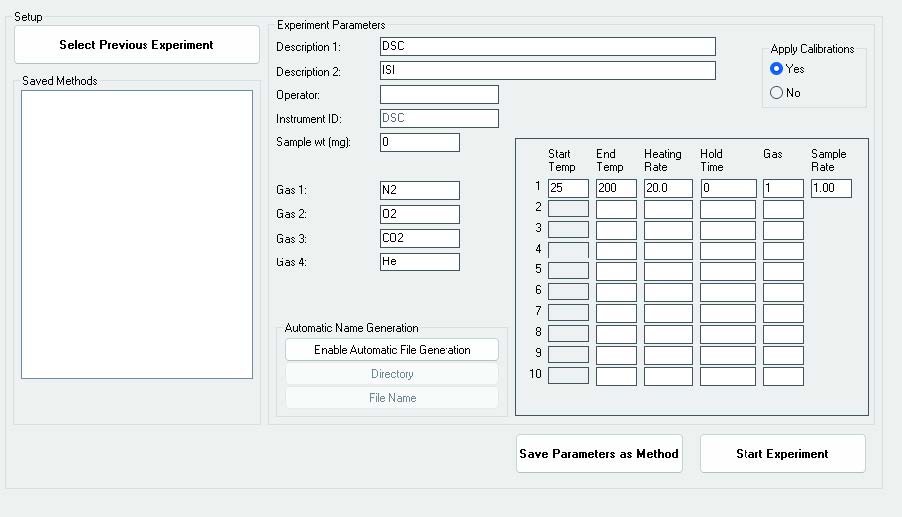

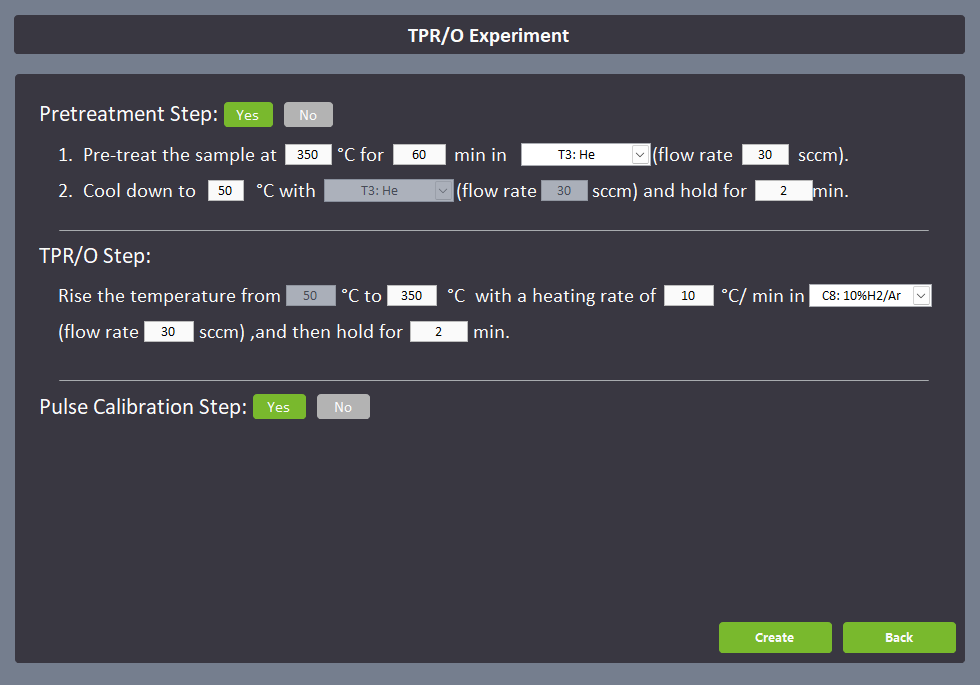

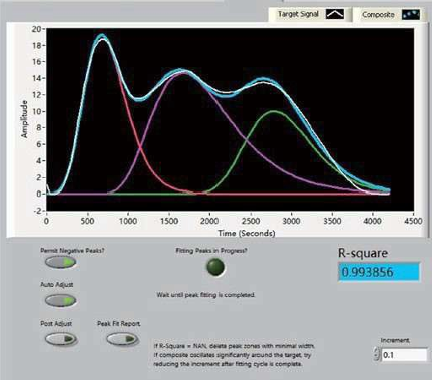

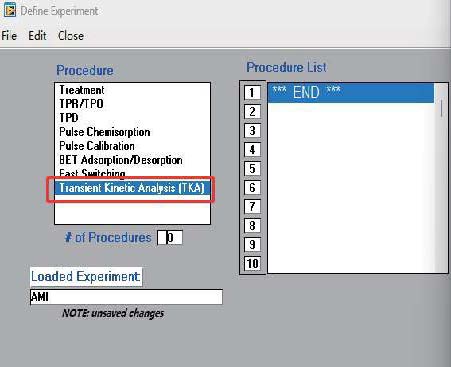

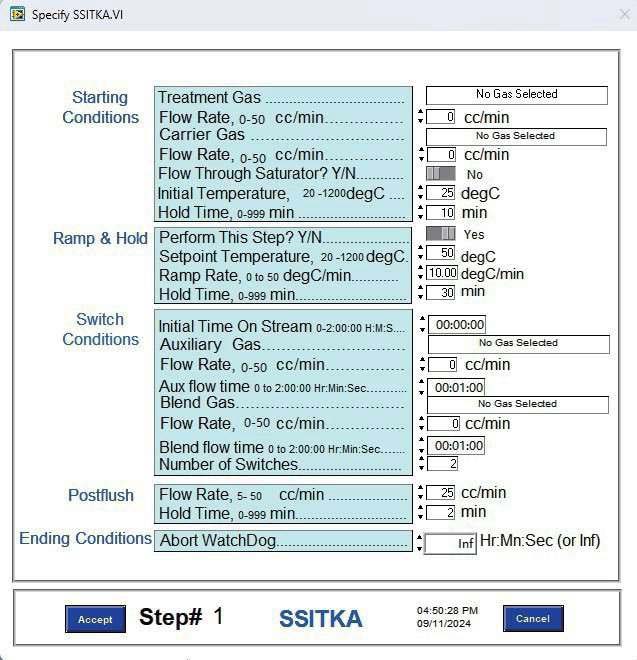

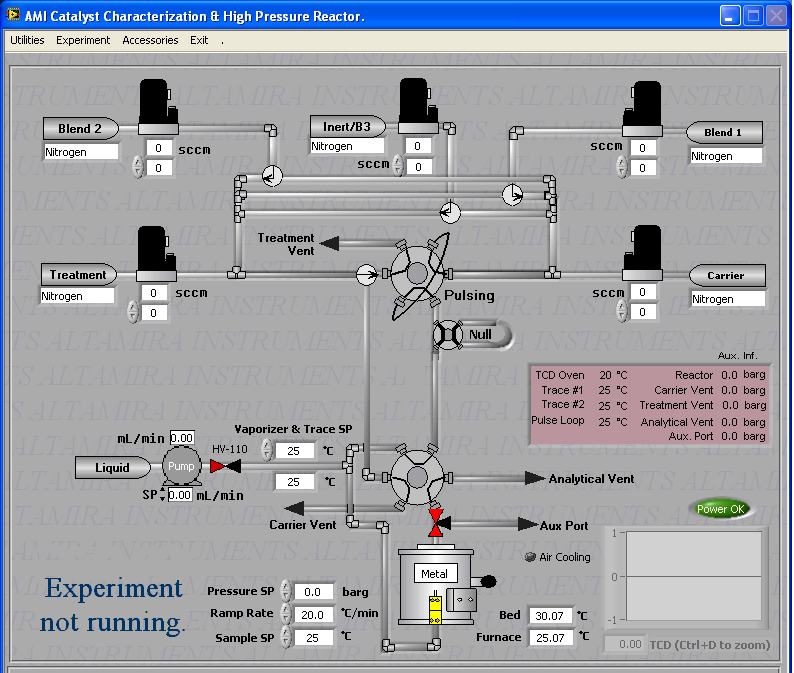

SOFTWARE

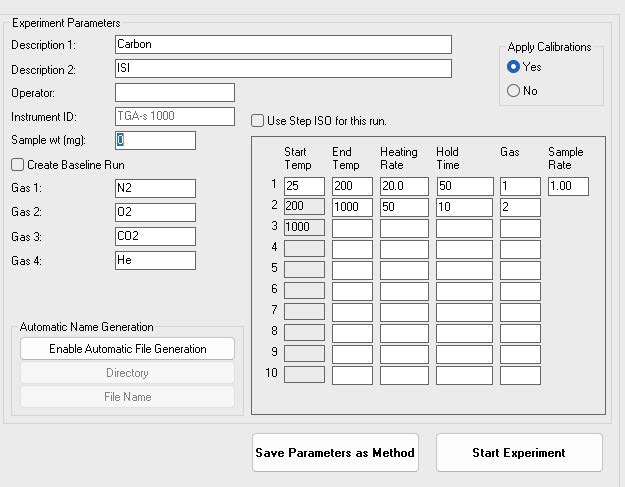

- Experiment Program Setup Interface

- Standard Functions

- · Glass transition analysis

(2-point or 6-point method) - · Onset/peak temperature determination

- · Peak integration

- · Melting peak analysis

- · Crystallinity measurement

- · Data smoothing

- · Baseline correction

- Optional Functions

- Specific Heat Capacity:

The system rapidly determines specific heat values by testing samples alongside reference materials with known heat capacity (e.g., sapphire) under identical conditions.

SPECIFICATIONS

| Temperature Range | -150~600°C | ||

| Temperature Accuracy | ±0.1°C | ||

| Temperature Precision | ±0.01°C | ||

| Program Rate | 0.1~200°C/min | ||

| Cooling Mode | Water Cooling | Refrigerated Cooling | Liquid Nitrogen Cooling |

| Maximum Temperature | 600°C | 450°C | 600°C |

| Minimum Temperature | Ambient Temperature | -40°C or -90°C | -150°C |

| Calorimetric Accuracy | ±0.1% | ||

| Noise | 0.5 μw | ||

| Gas | Nitrogen, Argon, Helium, Compressed air, Oxygen, etc. | ||

| Sampling Frequency | 10 Hz | ||

| Weight | 27 lbs. | ||

| Dimensions | 17 in(W) × 17 in(D) × 9.5 in(H) | ||

| Options | |||

| Gas Controller | 4 Channel Automatic Gas Switching | ||

| Software Functions | Specific Heat Capacity | ||

MATERIALS

- Thermoplastics

- Thermosets

- Rubbers

- Catalysts

- Phenolics

- Pharmaceuticals

- Chemicals

- Coals and other fuels

- Nuclear Research

- Foods

- Cosmetics

- Explosives

APPLICATIONS

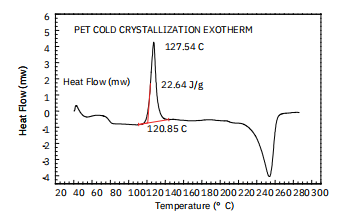

- Cold Crystallization Behavior of PET

- The crystal growth and degree of crystallization depend on the polymer type, cooling rate, or isothermal aging time. The calculation method for crystallization enthalpy is the same as that for melting enthalpy. Cold crystallization is the process of crystal growth during heating. This exothermic event precedes crystal melting.

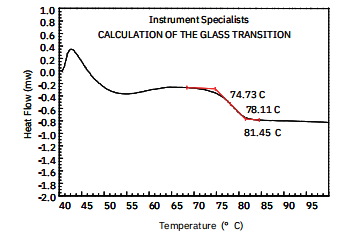

- Glass Transition Analysis

- The glass transition temperature (Tg) of polymers refers to the temperature range at which they transition from a rigid "glassy" state to a flexible "rubbery" state, significantly affecting their usability, particularly in elastomers. Understanding Tg is crucial for quality control, process optimization, ensuring product performance, and maintaining material consistency.

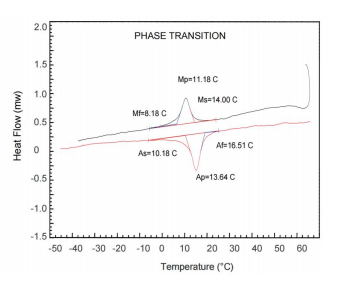

- Phase Transformation of Nickel-Titanium Alloys

- The Af temperature refers to the phase transition temperature of nickel-titanium alloys, marking the transformation from the high-temperature phase (a-phase) to the low-temperature phase (f-phase). In the high-temperature phase, the crystal structure of nickel-titanium alloy exhibits a cubic system, while in the lowtemperature phase it transforms into a monoclinic system. This phase transition temperature change gives nickel-titanium alloys their shape memory properties. These shape memory characteristics enable important applications across various fields, such as medical devices, aerospace, and mechanical engineering.

ACCESSORIES

- Crucibles

- Crucibles serve as sample containers in thermal analysis measurements, effectively protecting sensors and preventing measurement contamination. The selection of crucible type is critical for result quality. We offer various crucible options to meet different testing requirements, ensuring accurate and reliable measurement results.

- Pellet Press

- The crucible pellet press elevates sample encapsulation to higher performance and convenience, suitable for routine and hermetic testing of various materials. The standard model is specifically designed for solid sample crucibles, while the universal model handles both solid and liquid sample crucibles, offering greater flexibility for your experiments.

- Fully Automated Chiller

- The fully automated recirculating bath enables precise continuous temperature control within the range of -10°C to 90°C. When coupled with the water-cooled DSC 600 system, it achieves rapid furnace cooling, significantly enhancing experimental efficiency.

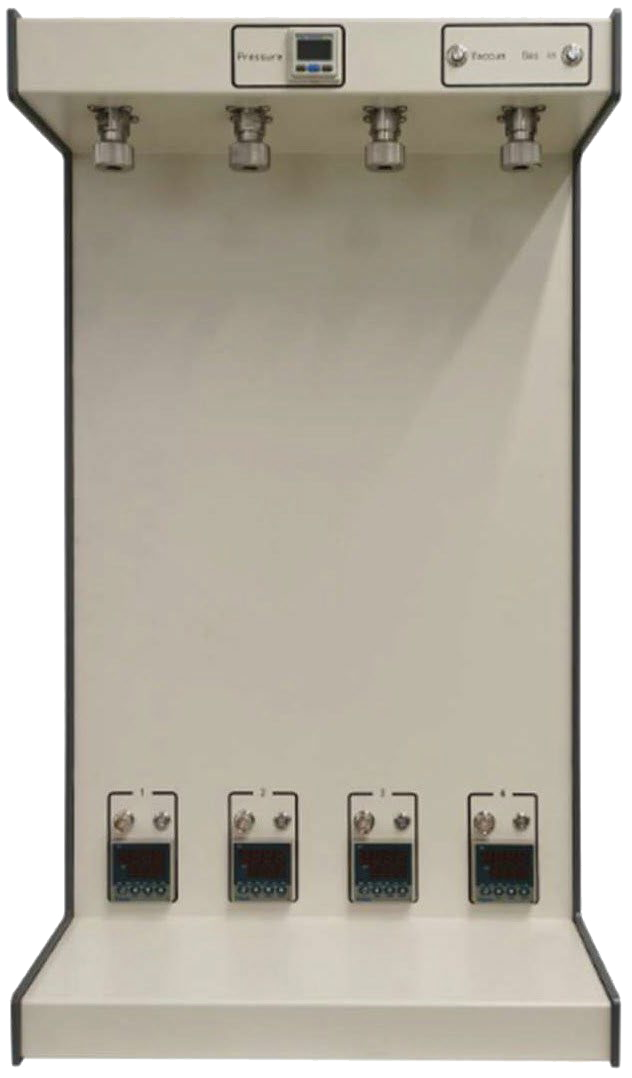

- Gas Selector Accessory

- The gas selector supports one-button switching across multiple gases, accommodating up to 4 input ports. It simplifies valve disassembly and assembly when sampling different gases, effectively minimizing leakage risks associated with manual handling. Additionally, the instrument features an automatic purging process, ensuring efficient gas line purification and seamless, automated switching between gases.

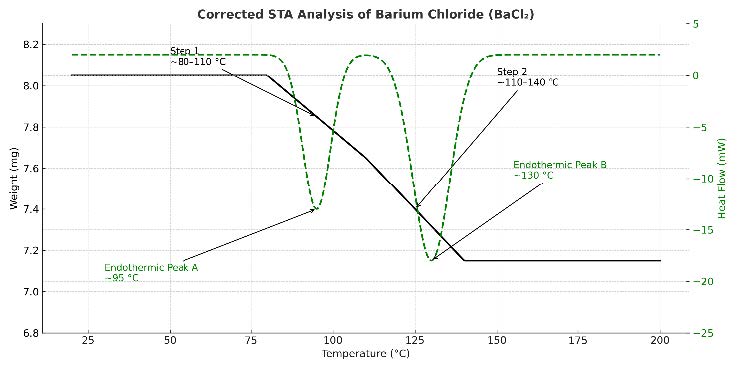

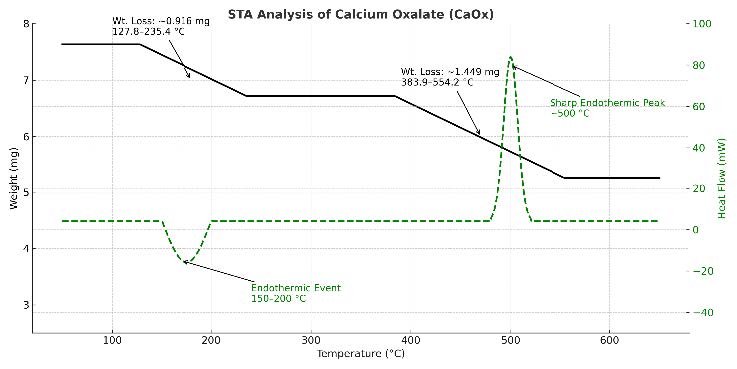

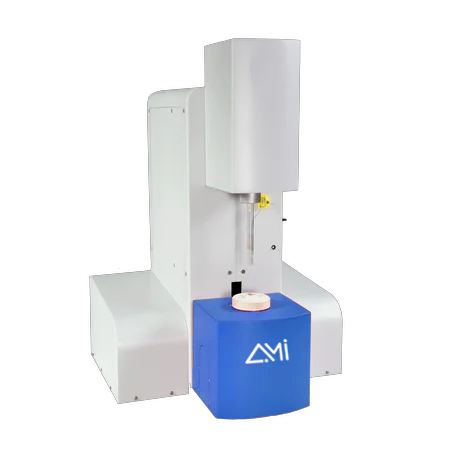

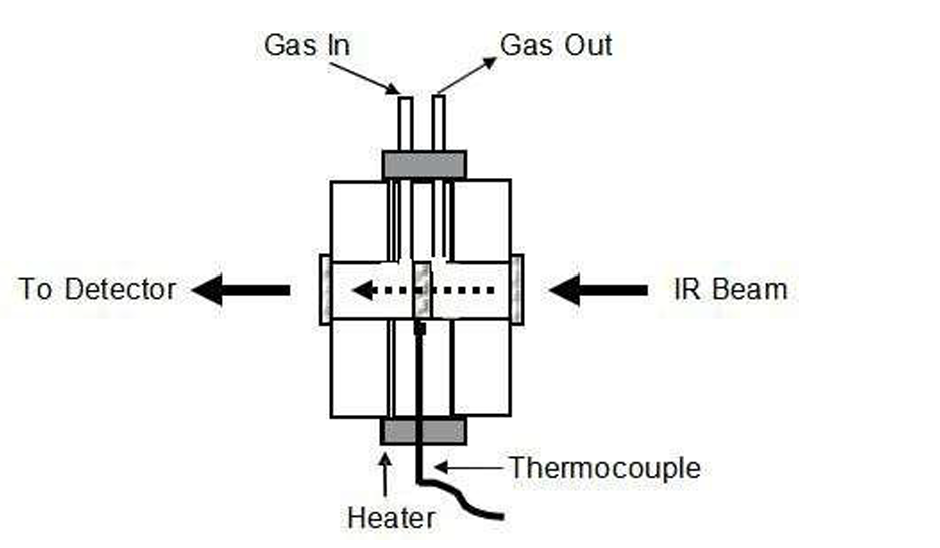

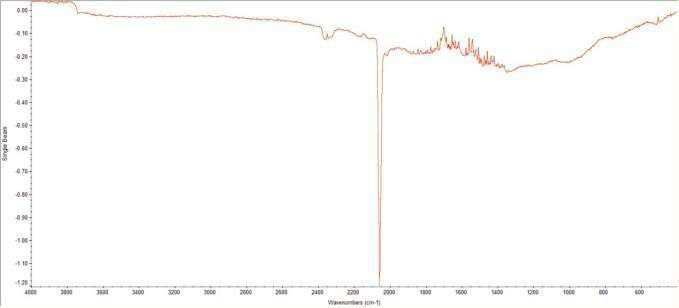

PDSC

- Pressure Differential Scanning Calorimeter

- The Pressure Differential Scanning Calorimeter (PDSC) is capable of conducting calorimetric tests under both high and low-pressure conditions. In practical applications, many raw materials and finished products are processed or used under high temperature and high pressure, making it essential to understand their performance under these extreme conditions. While traditional calorime-ters are effective in characterizing the physical and chemical properties of materials, the PDSC extends this characterization to extreme pressure environments. It allows for an in-depth analysis of the heat flow changes during phase transitions and chemical reactions under high or low pressure.

- In a sealed crucible, changes in internal pressure can cause DSC test results to differ from those obtained under atmospheric pressure. The PDSC enables precise pressure control, which allows researchers to investigate the effects of varying pressures on samples and uncover thermal behavior differences in different environments. For material research in extreme test conditions, the PDSC offers superior capabilities in characterizing heat changes during reaction processes.

- At the core of the PDSC is a high-performance heat flow sensor platform, specifically designed to study minute energy changes and the relationship between energy, temperature, and pressure.

-

Temperature Range -150-600°C Maximum Pressure 1000 psi Program Rate 0.1-200°C/min Gas Nitrogen, Argon, Helium, Compressed air, Oxygen, etc.

AMI Thermal Analysis Series Products

- Differential Scanning

Calorimeter

(DSC)

- Thermogravimetric

Analyzer

(TGA)

- Simultaneous Thermal

Analyzer

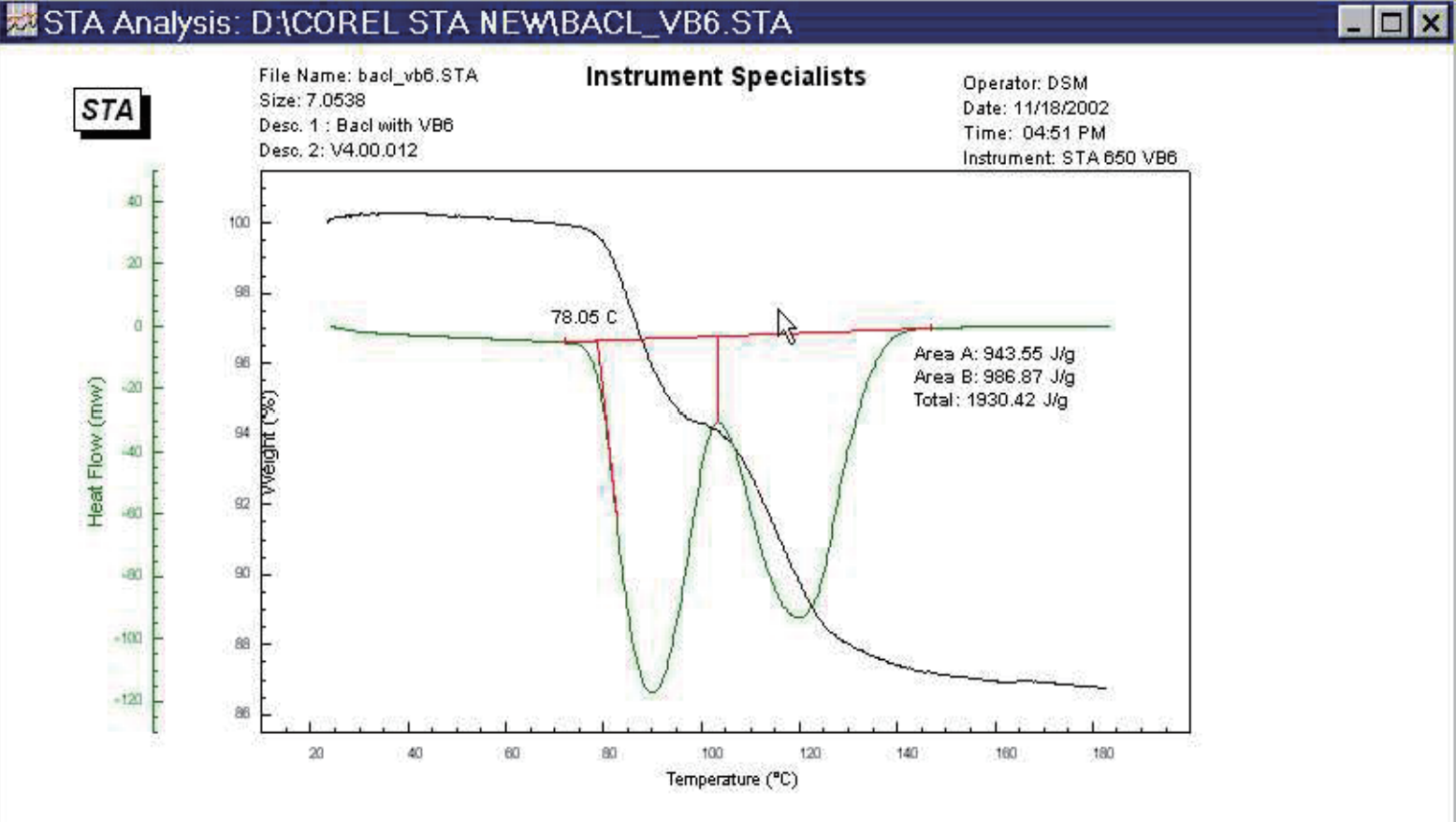

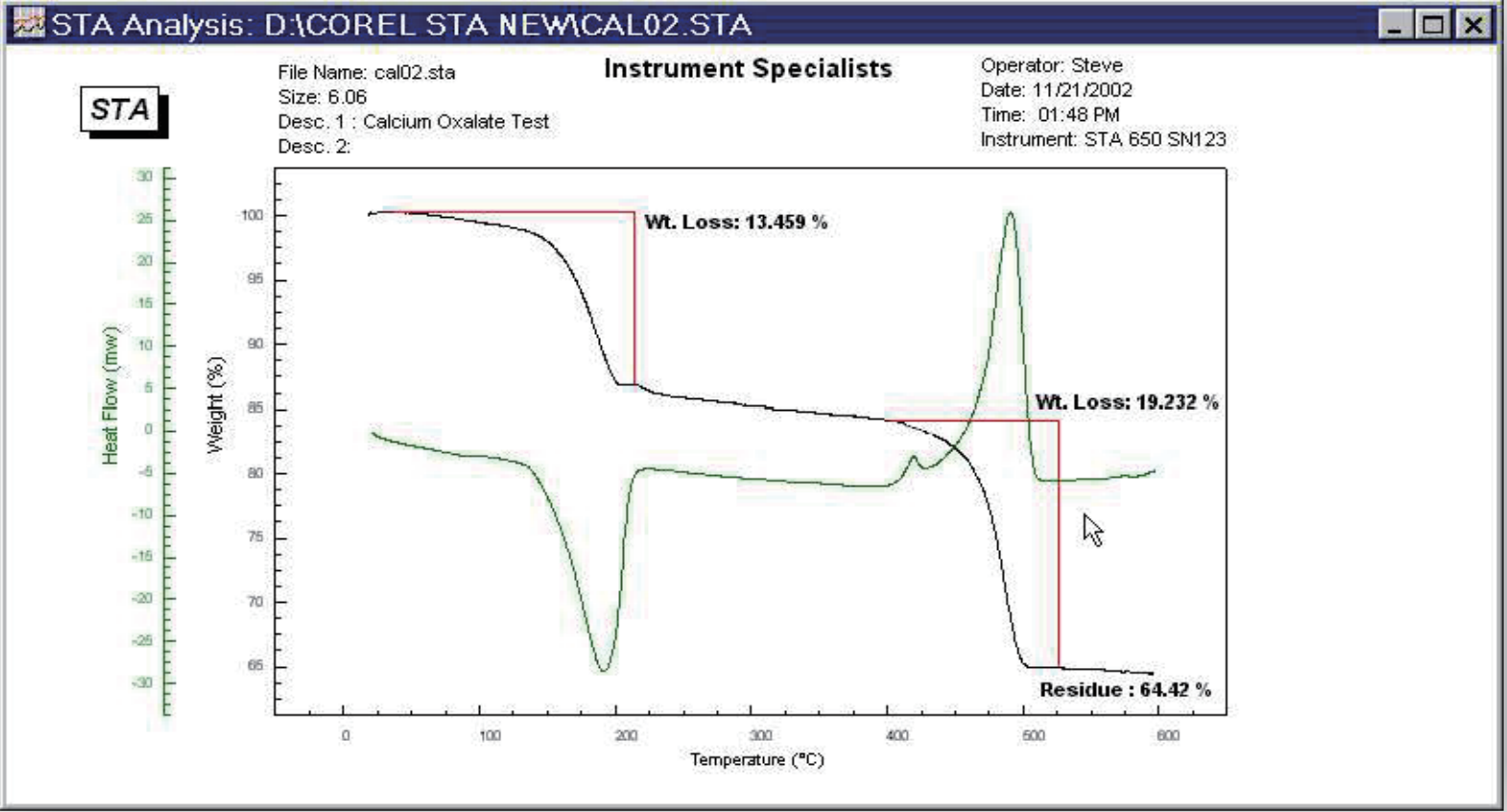

(STA)

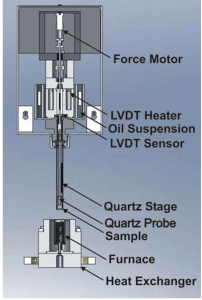

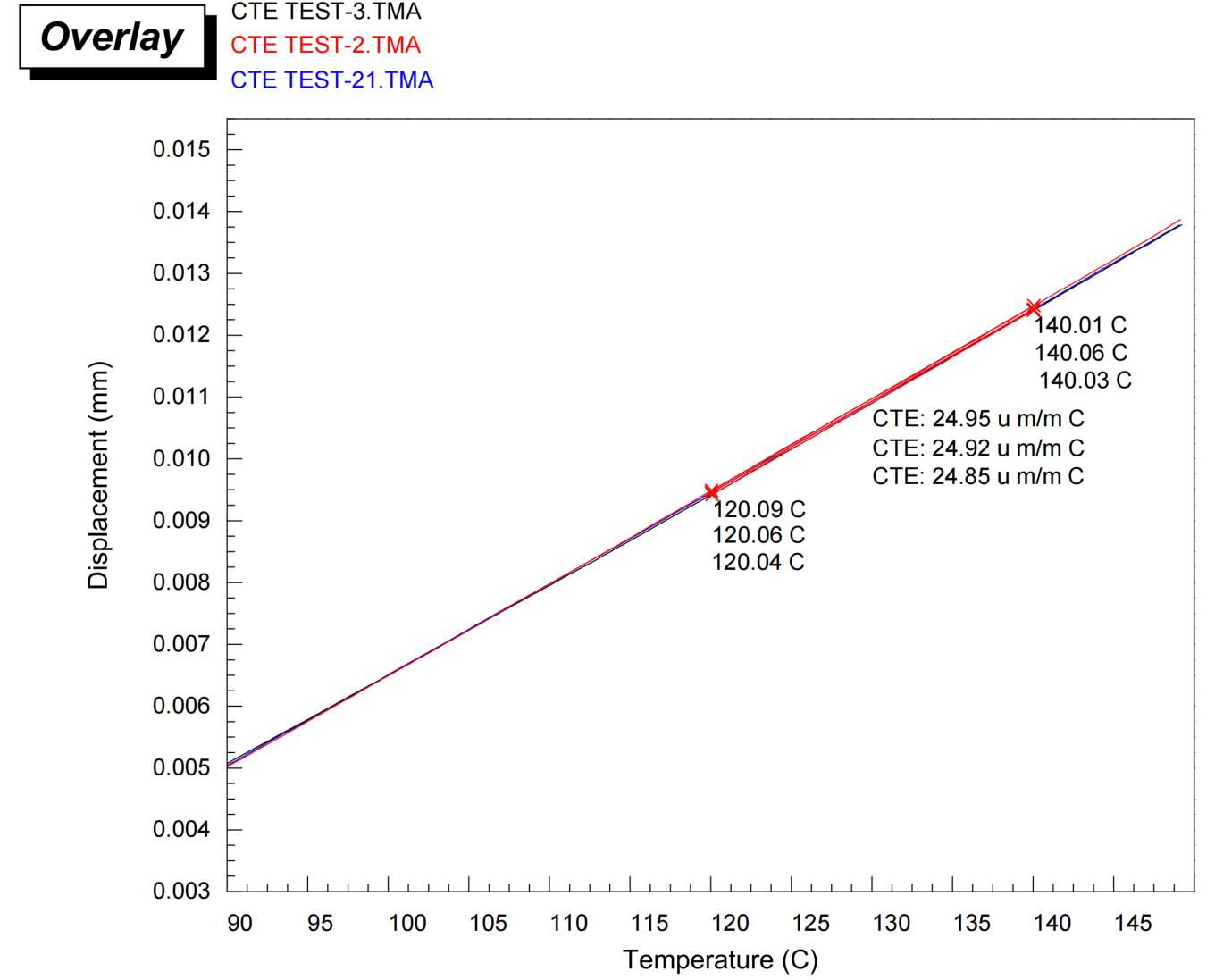

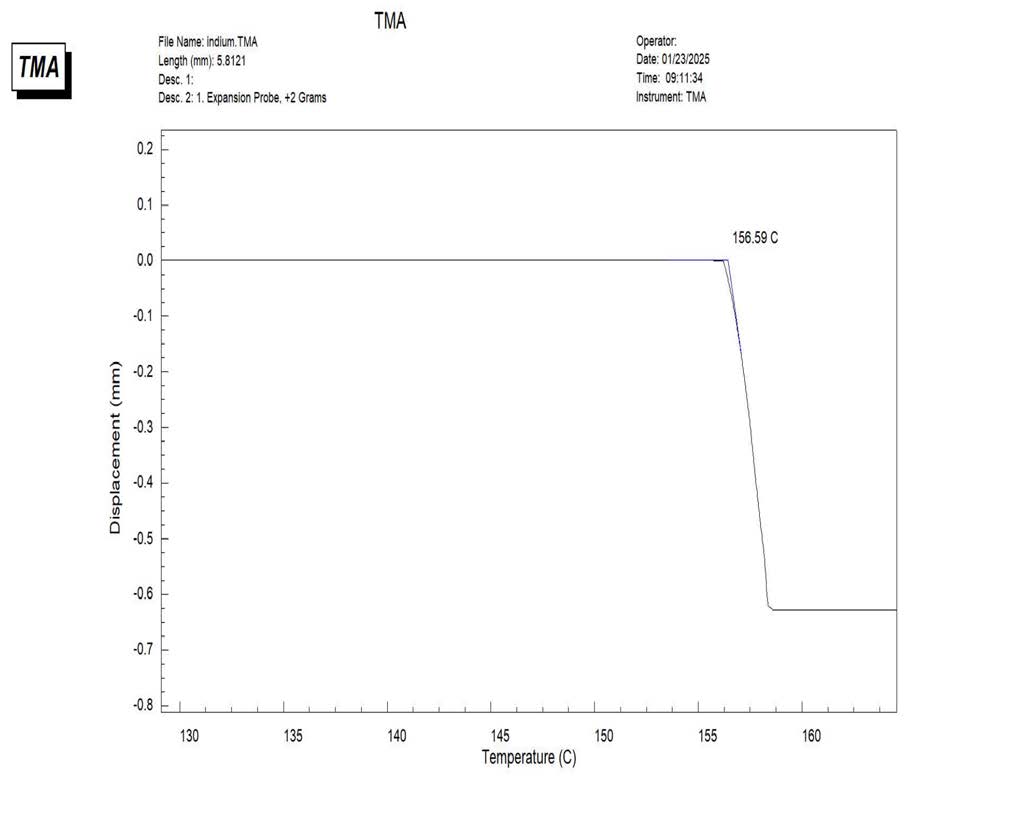

- Thermomechanical

Analyzer

(TMA)

Products

Products

Products

Products

-1.png)

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com