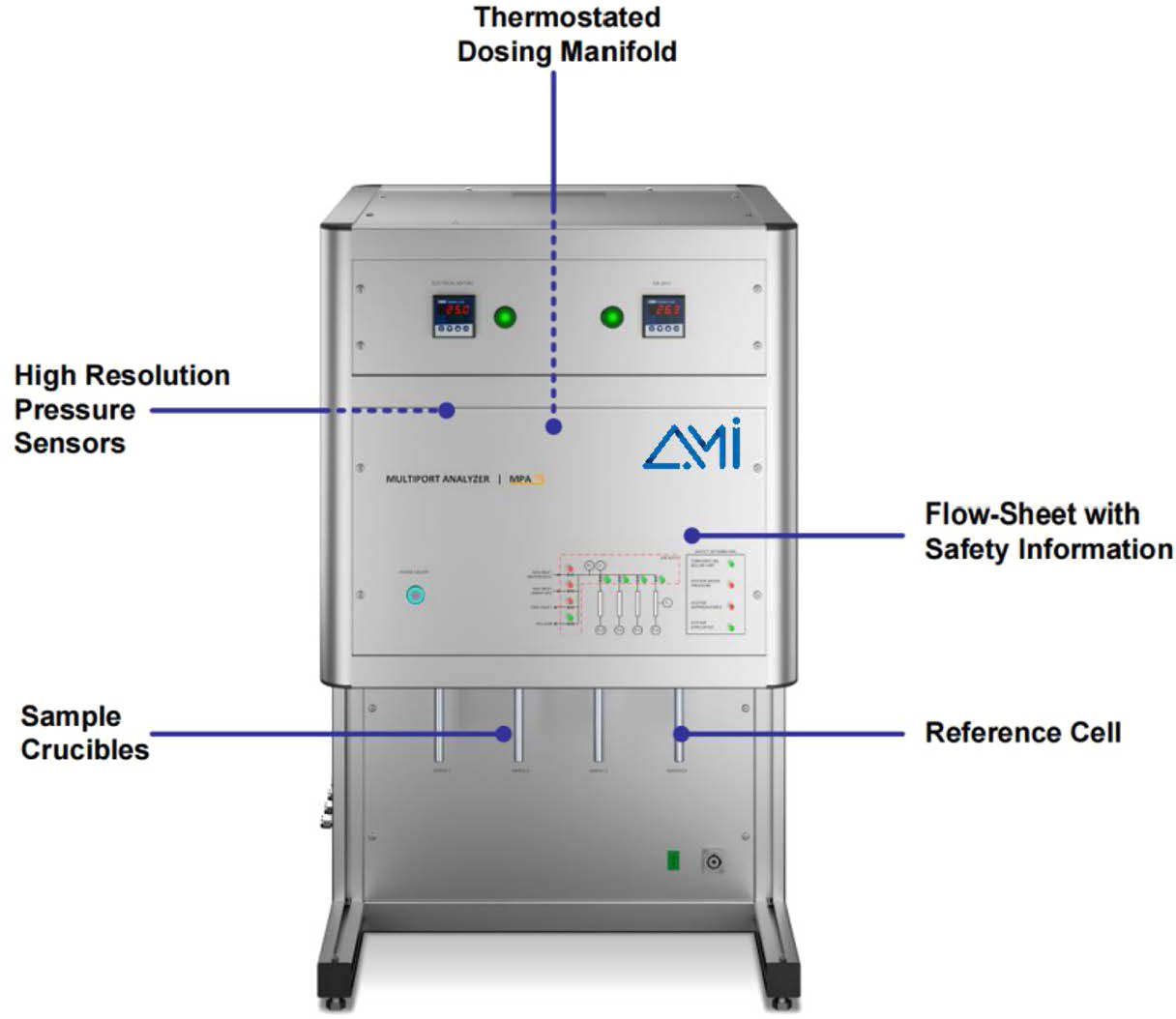

- The RuboSORP MPA is a cutting-edge, high-pressure volumetric adsorption instrument designed for accurate and reliable pressure-composition-temperature (PCT) measurements up to 200 bar. Engineered for precision and efficiency, it provides deep insights into gas adsorption behavior, enabling researchers to analyze surface properties, storage capacity, and cycling kinetics with unmatched accuracy.

- With its versatile capabilities, the RuboSORP MPA is the ideal solution for:

- ✔ Hydrogen storage material evaluation

✔ Shale gas and coal bed methane studies

✔ CO₂ capture and sequestration research

✔ Air purification and adsorbent performance testing - Built for precision, reliability, and multi-sample efficiency, the RuboSORP MPA empowers scientists and researchers in developing next-generation energy and environmental solutions. Advance your research with the RuboSORP MPA—where accuracy meets innovation.

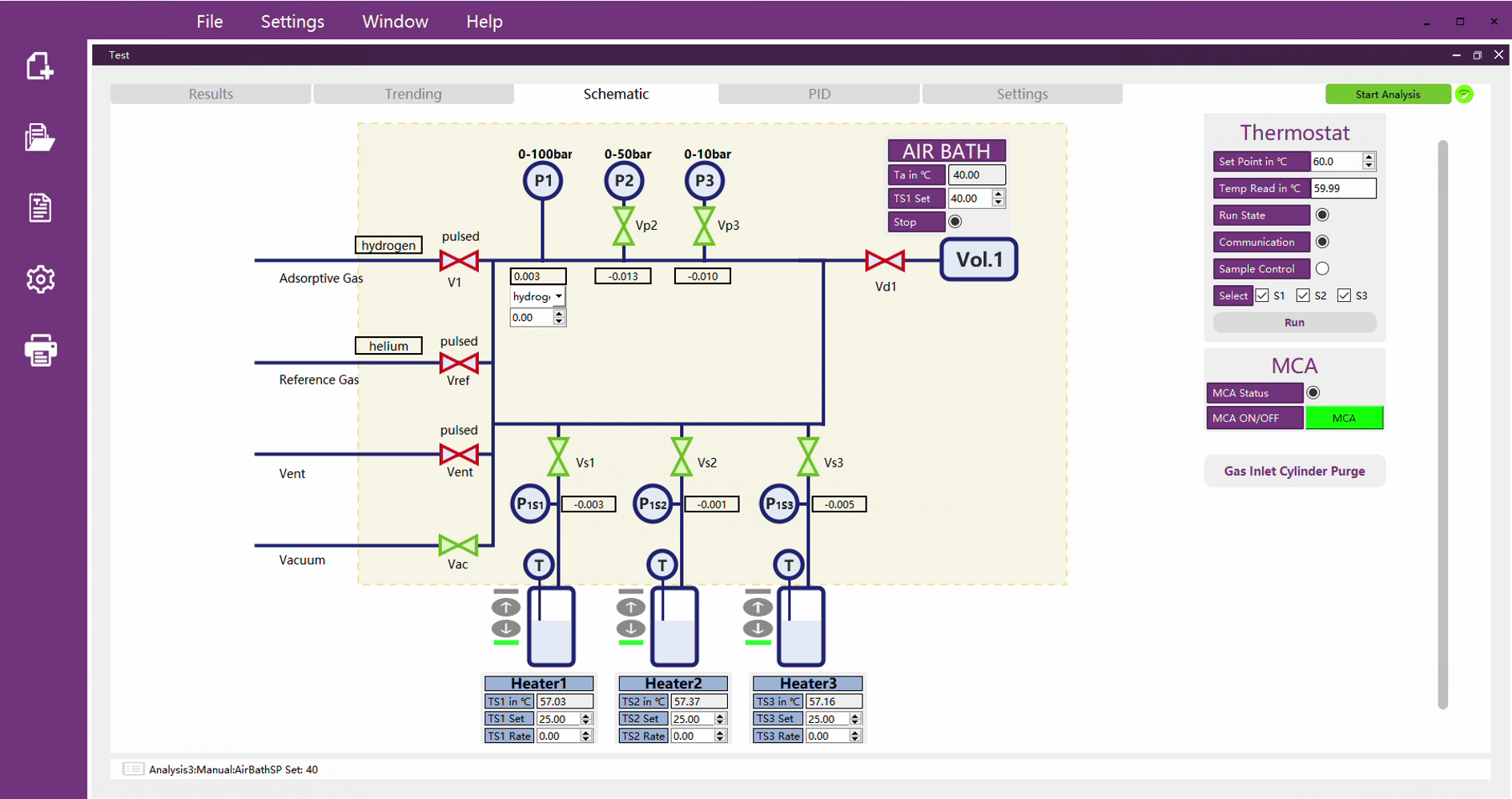

- High-Pressure Volumetric Sorption:

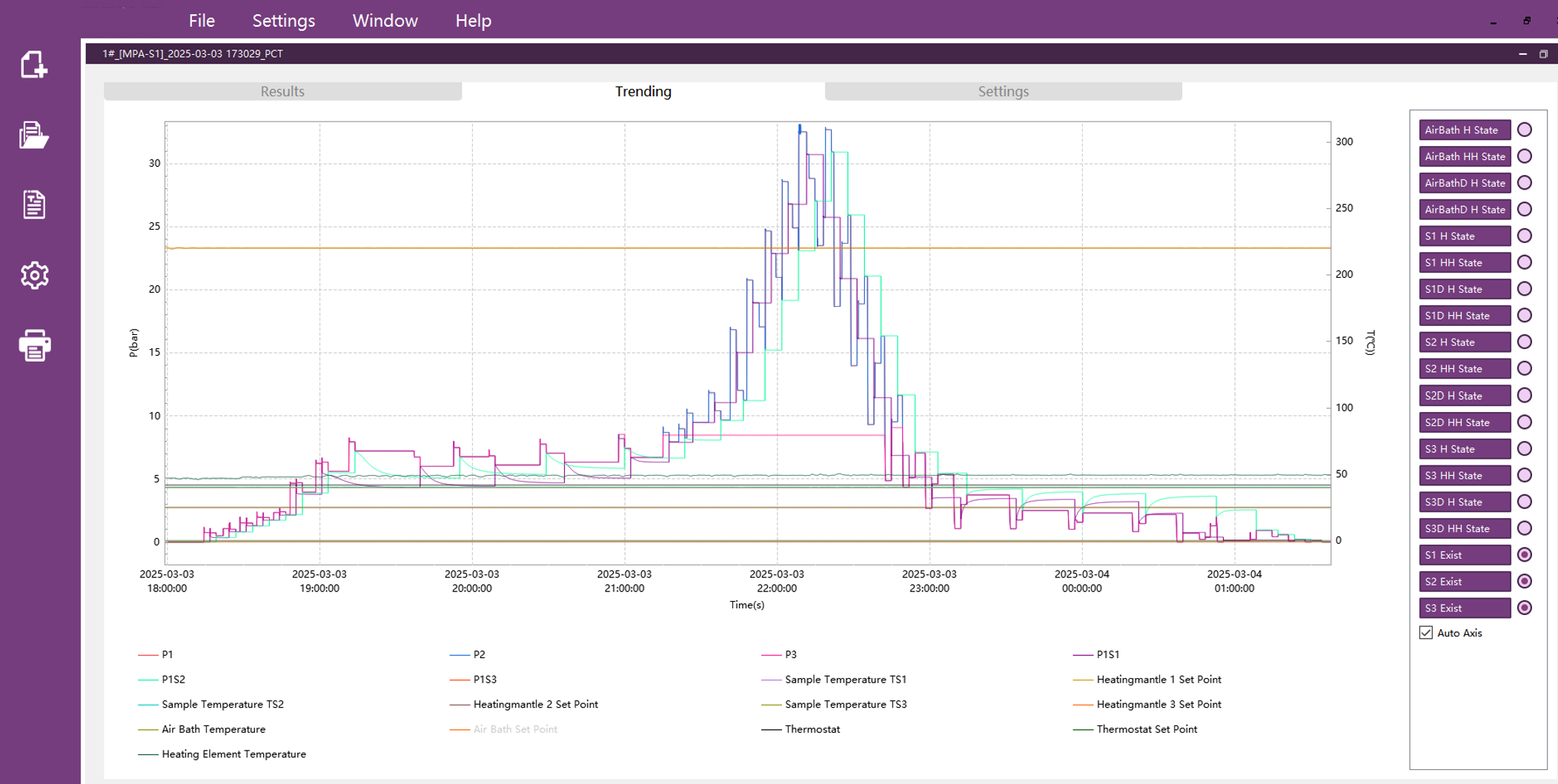

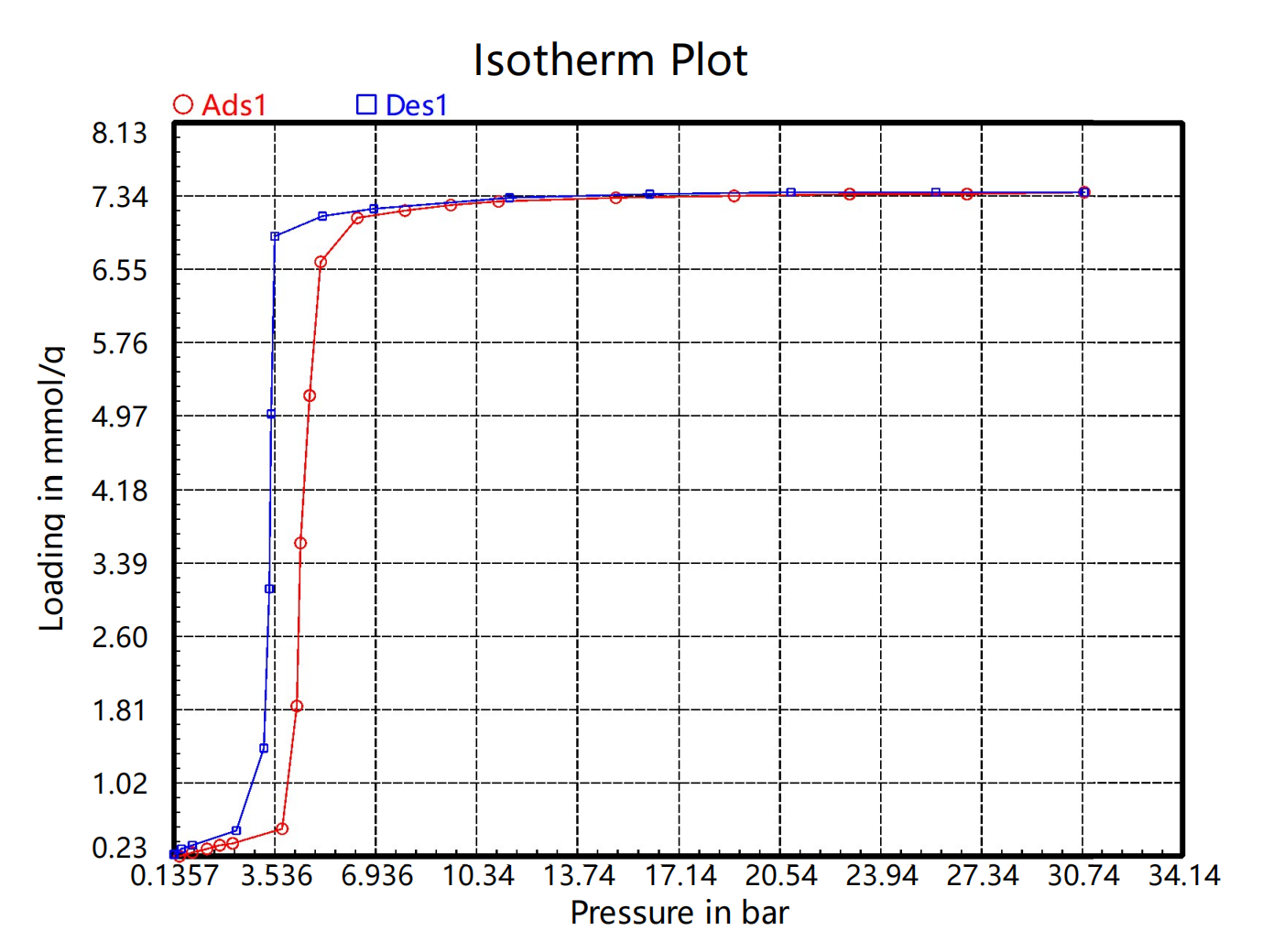

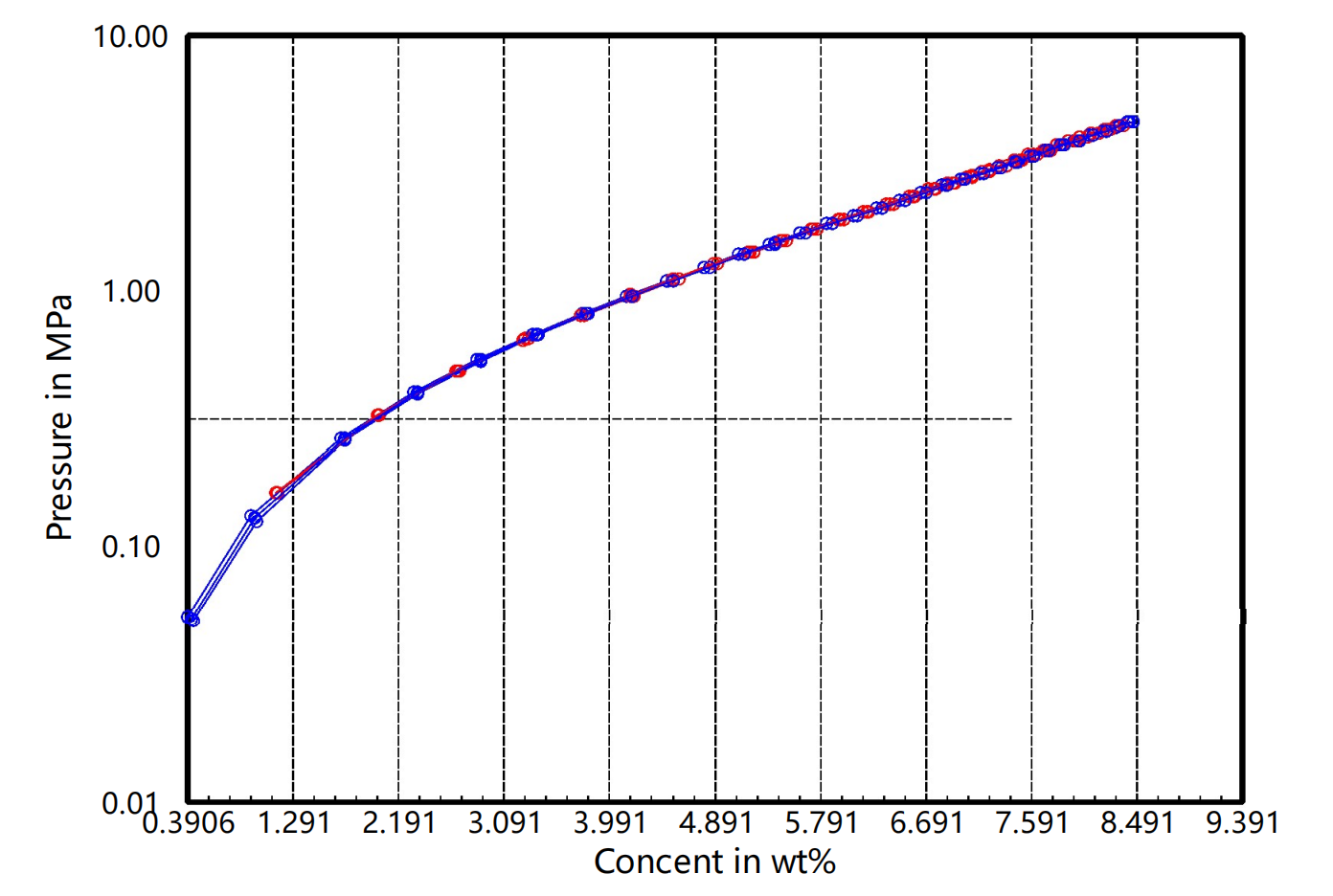

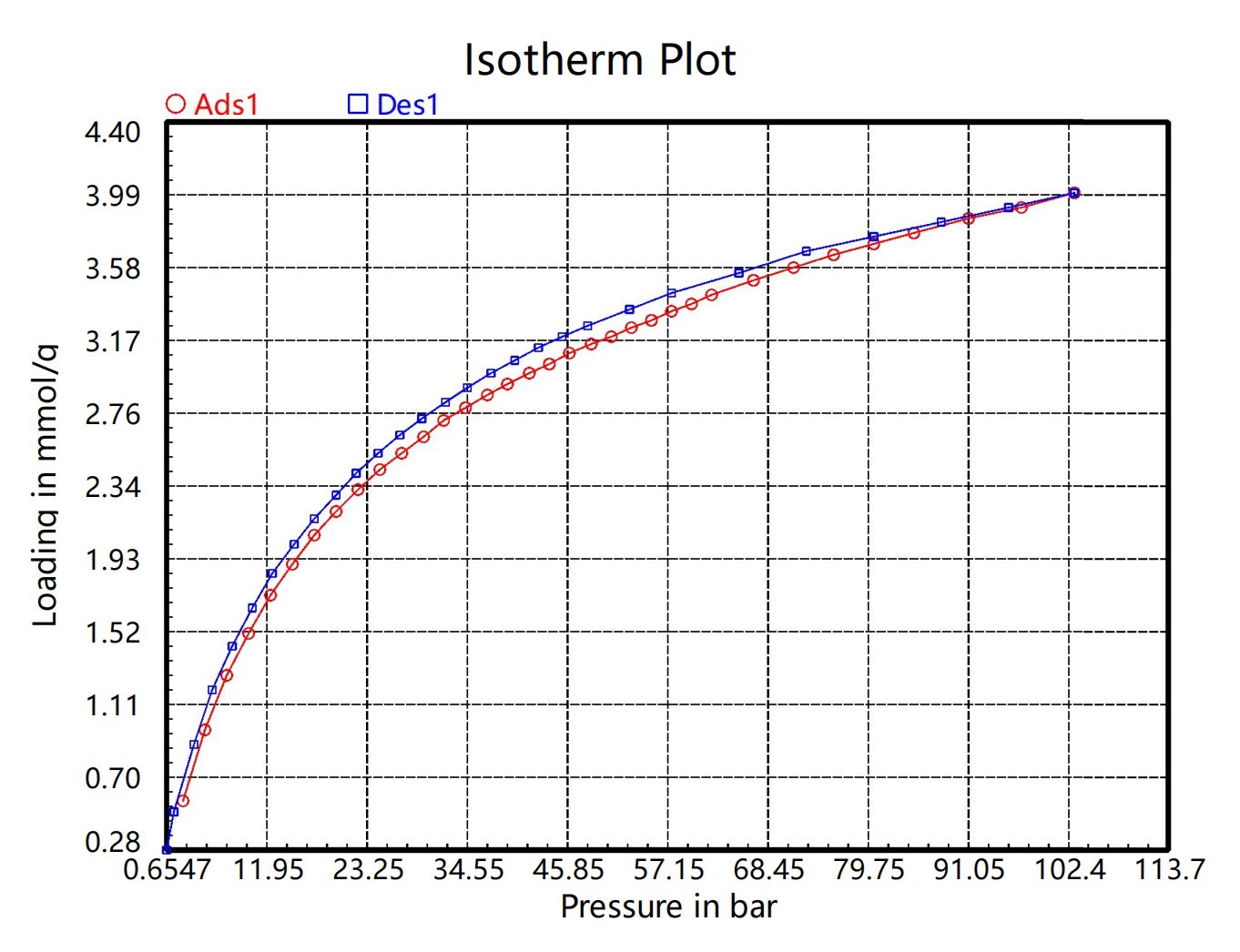

- PCT and other gas adsorption/ desorption isotherms

Cycling PCT isotherm measurements

Adsorption kinetics

Cycling kinetic measurements

Dead volume measurements

Advanced Measurement Instruments

Copyright © 2025 Advanced Measurement Instruments

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com