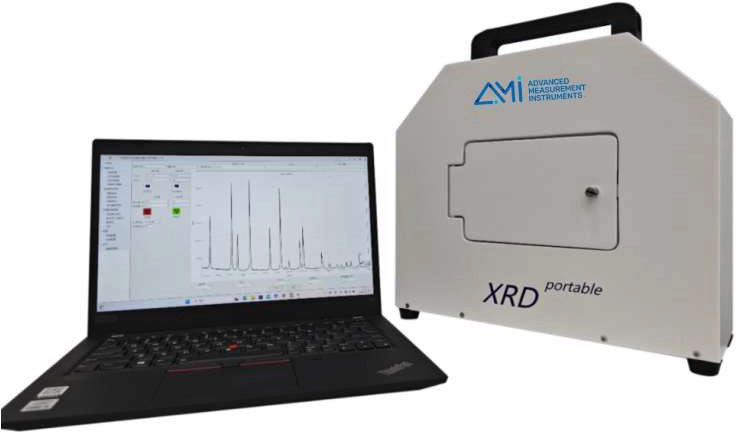

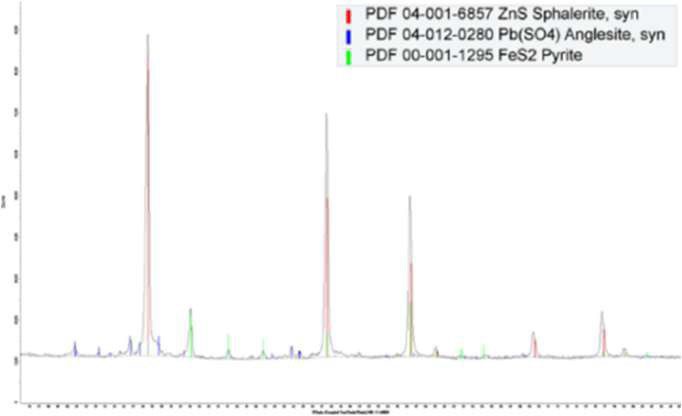

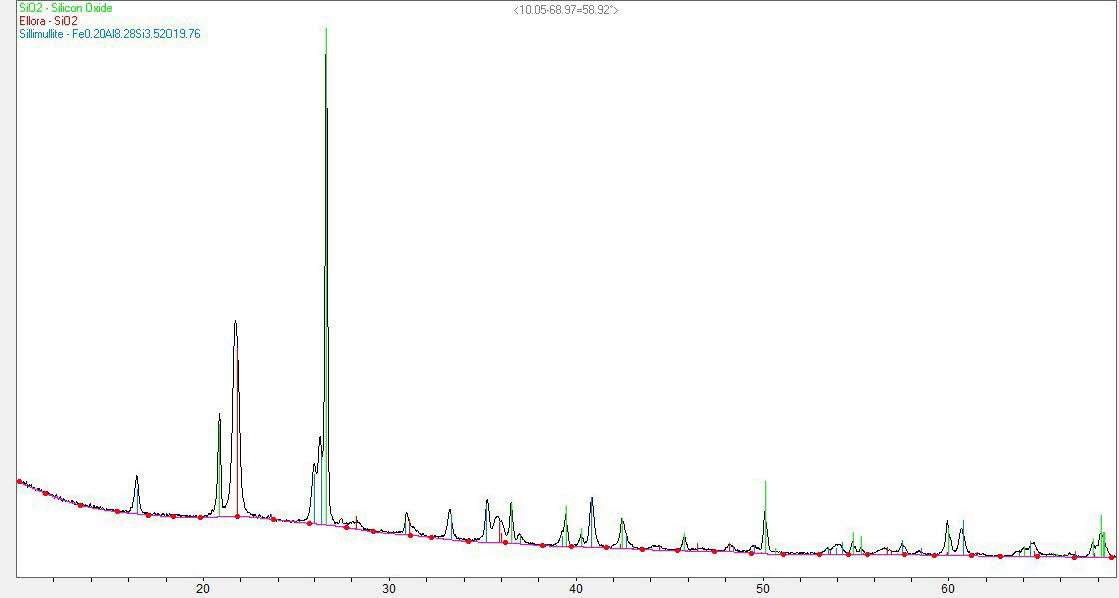

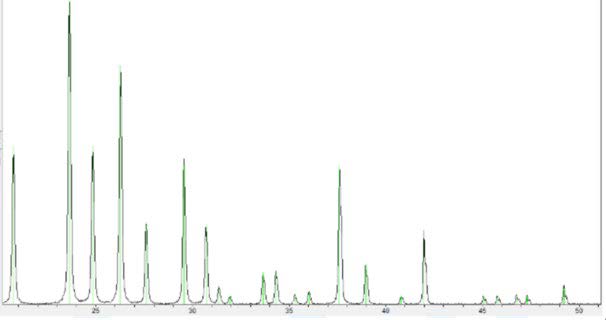

- The Lattice GO redefines portable X-ray diffraction, delivering laboratory-grade performance in a compact, lightweight system. Designed for versatility, it integrates a specialized X-ray source, Bragg-Brentano diffraction geometry, and an advanced 2D array detector to generate high-quality XRD spectra in minutes.

- Optimized for field research, on-site quality control, and space-constrained laboratories, the Lattice GO provides high-intensity data with exceptional angular precision, rivaling traditional benchtop systems. Its rugged construction, rapid scanning capability, and user-friendly operation ensure reliable results in any environment.

- With the Lattice GO, high-resolution diffraction is no longer confined to the lab—bringing powerful material analysis wherever it's needed.

Advanced Measurement Instruments

Copyright © 2025 Advanced Measurement Instruments

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com