Magnetic suspension balance. Gravimetric sorption in real-world conditions. Dual-sample testing, up to 400°C.

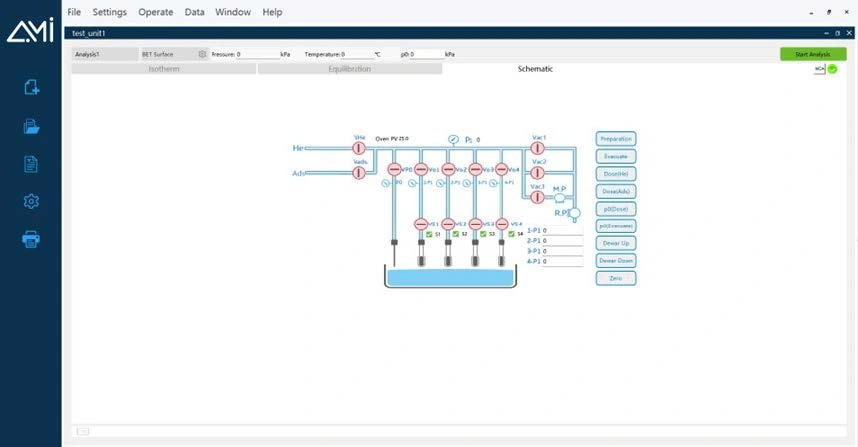

Multi-Station Architecture

Run up to four fully independent analysis stations per unit—each with dedicated dosing, pressure control, and data acquisition. Scale up to 12 stations by connecting three Matrix 1000 units. Ideal for high-throughput labs and multi-user environments.

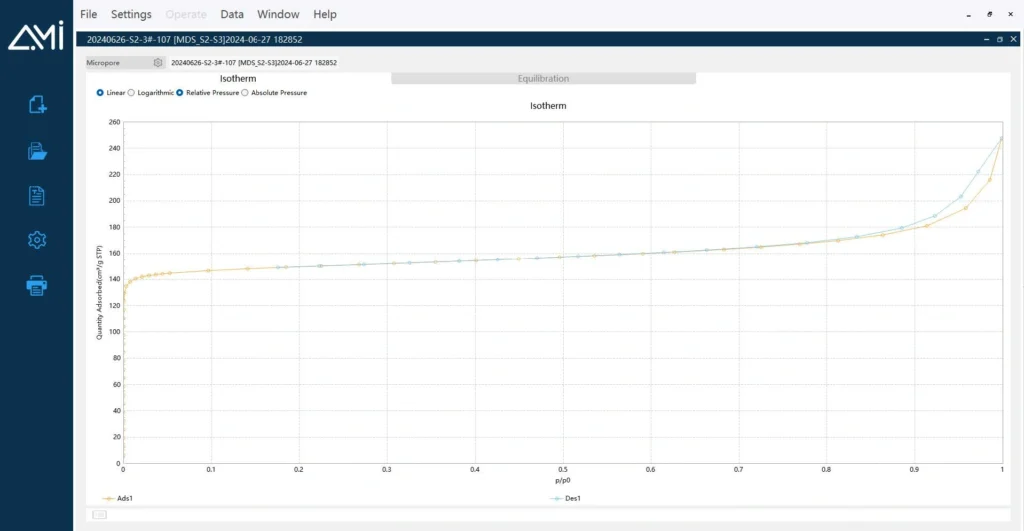

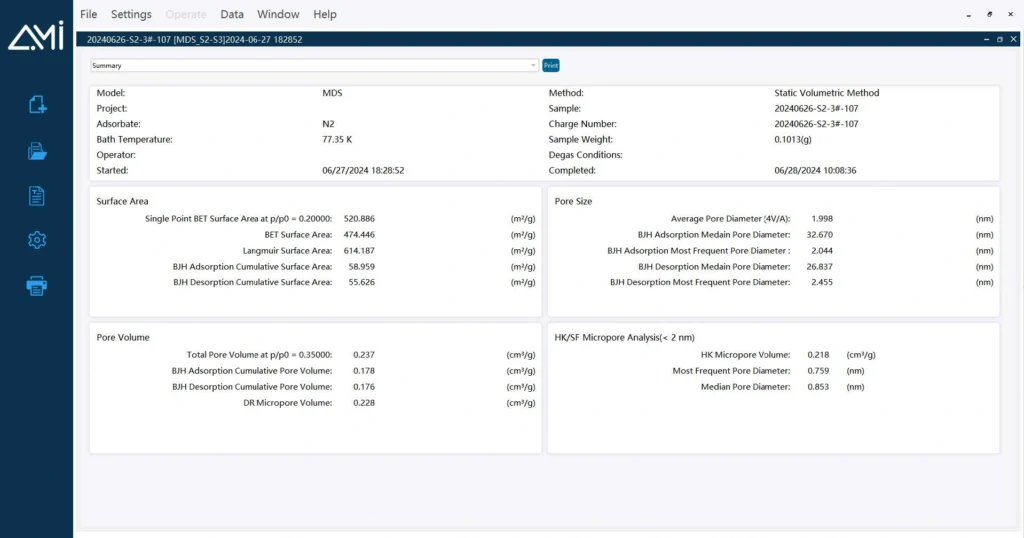

Micropore & Mesopore Flexibility

Configure any combination of micropore or mesopore analysis stations based on your application needs. High-resolution pressure sensors—down to 0.1 Torr—enable accurate characterization of ultrafine pores, while broader pressure ranges allow robust mesopore and macropore analysis.

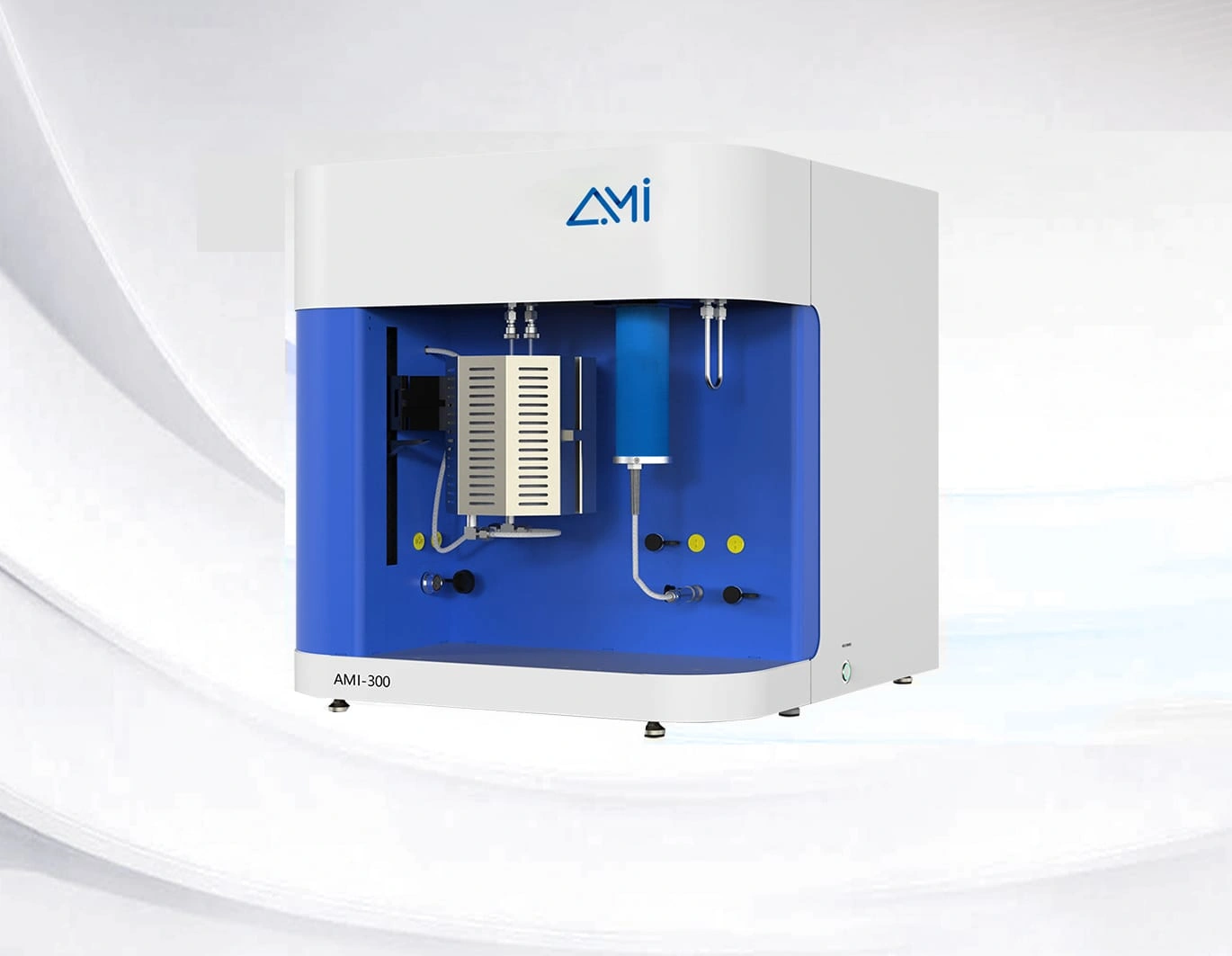

Smart Safety & Status System

The Matrix 1000 is built for safe, intuitive operation. Each work unit includes multicolor LED indicators for quick visualization of instrument status:

• White – Standby

• Orange – Heating

• Green – Test in Progress

• Red – Alarm Condition

Real-time monitoring of pressure and temperature ensures that any anomaly automatically triggers an alarm, switches the unit to red warning status, and halts the experiment for safety. A retractable front safety shield protects users from cryogenic splashes during operation.