AMI-Sync Series

INTRODUCTION

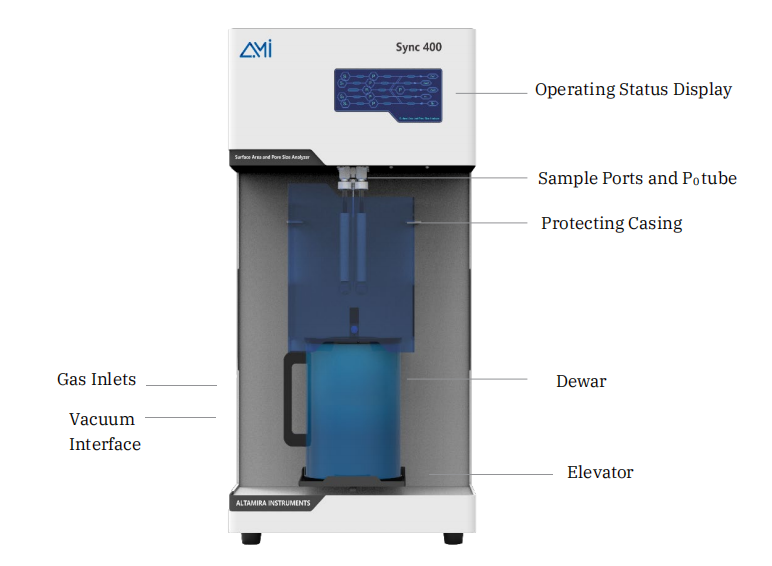

- The AMI-Sync Series is a fully automated, high-performance line of gas physisorption analyzers designed for rapid and accurate surface area and pore size characterization of porous and non-porous materials. Whether analyzing catalysts, zeolites, MOFs, or advanced battery materials, the AMI-Sync Series delivers robust vacuum-volumetric measurement systems backed by intuitive software and comprehensive support for both standard and advanced adsorption techniques.

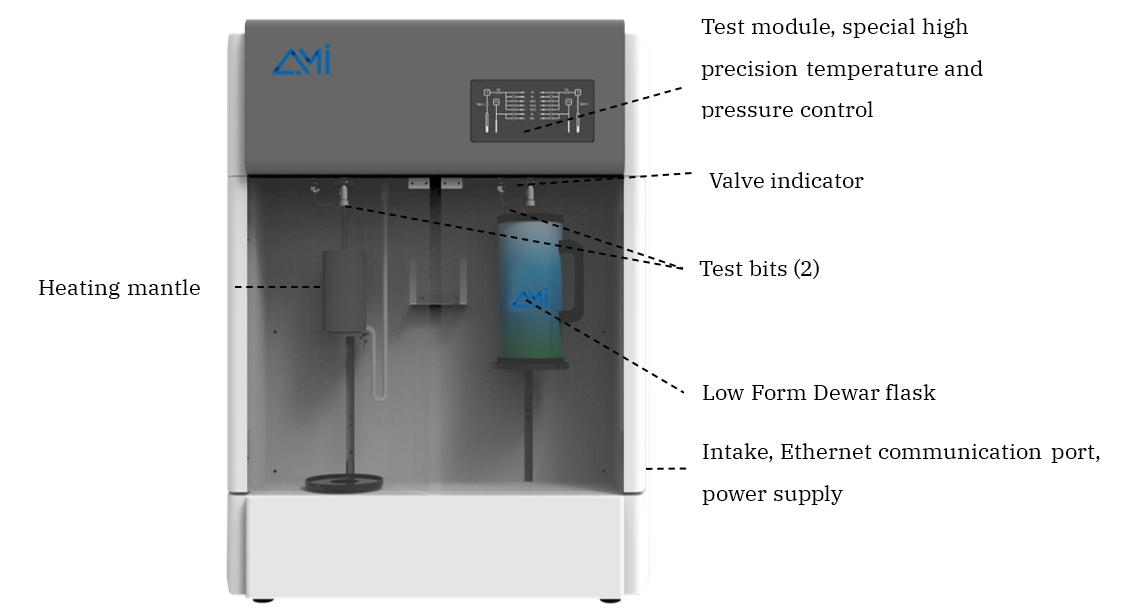

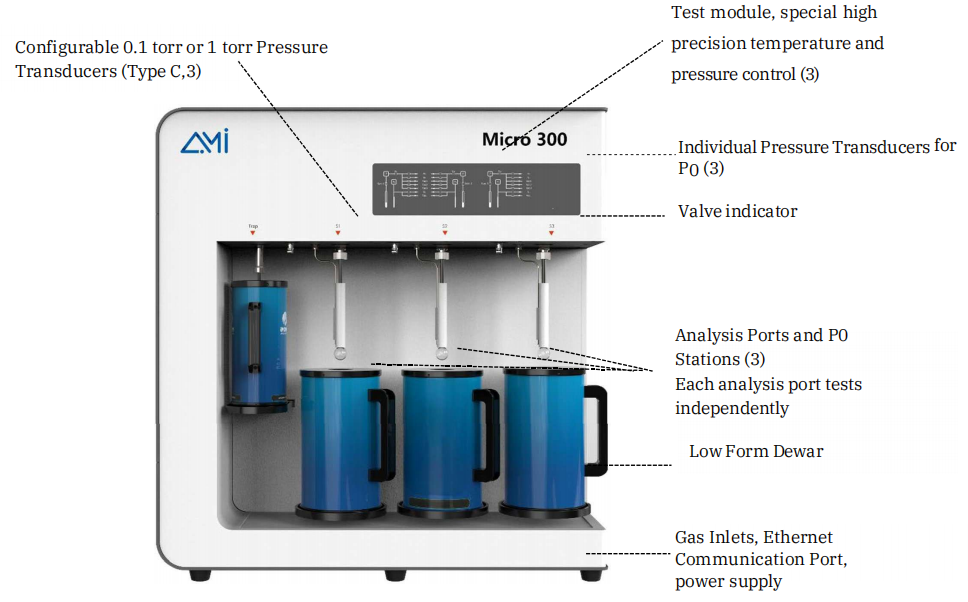

- Available in flexible 1-, 2-, or 4-station configurations, the AMI-Sync Series features a common P₀ measuring transducer and supports simultaneous saturation vapor pressure measurements. Each unit is built for high-throughput performance, with options for a dedicated pressure transducer per station to maximize speed, or a shared sensor setup for cost efficiency. A single large-volume dewar supports multiple stations simultaneously, offering an ideal solution for space-conscious laboratories with demanding workloads.

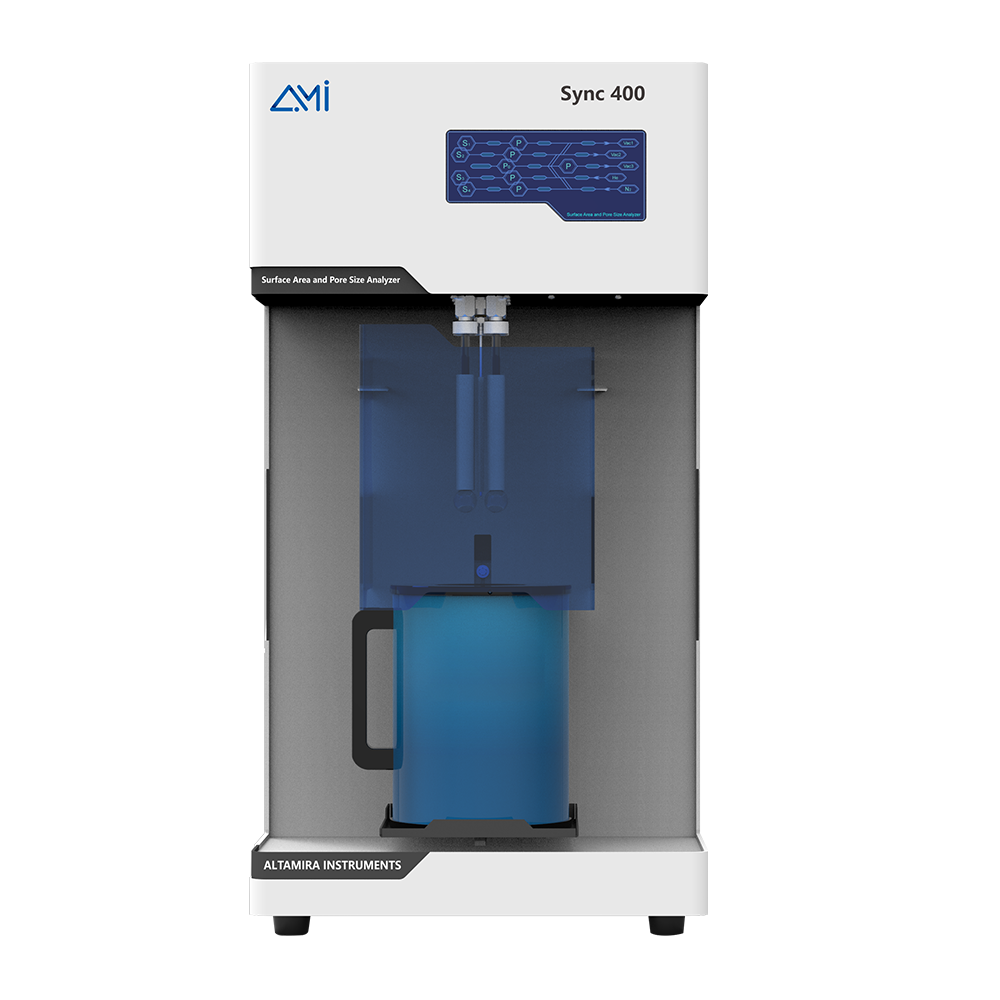

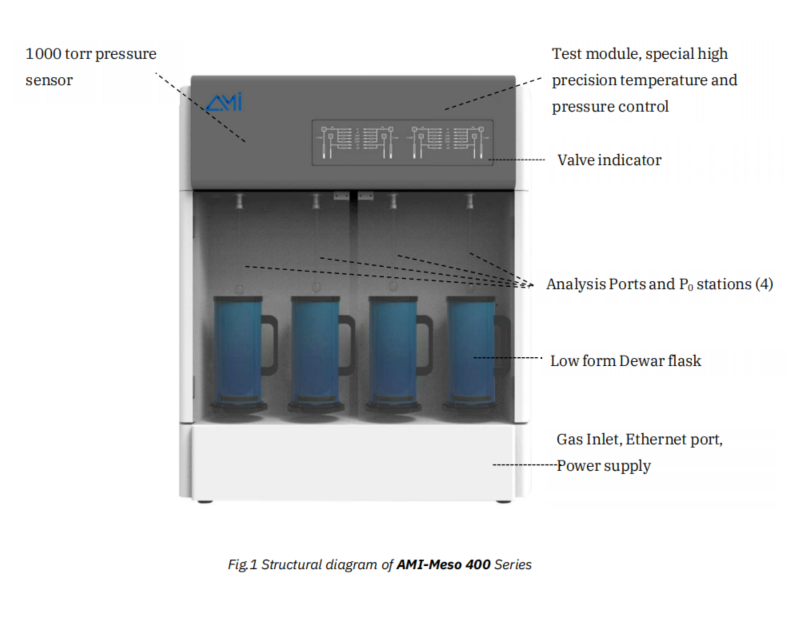

- AMI-Sync 400 Series Instrument

KEY FEATURES

- Customizable Configuration for Throughput Analysis Needs

- The AMI-Sync series offers a scalable solution with up to four high-resolution measurement stations for precise pore size and surface area analysis. For increased throughput, additional instruments can be linked via LAN, expanding to 12 analysis ports with centralized and remote-control capabilities.

- Extended Analysis Duration

- AMI-Sync analyzers are equipped with large 3-liter Dewar flasks that allow over 90 hours of continuous analysis. The system supports live refilling during experiments, ensuring uninterrupted data collection during long runs and complex isotherm acquisitions.

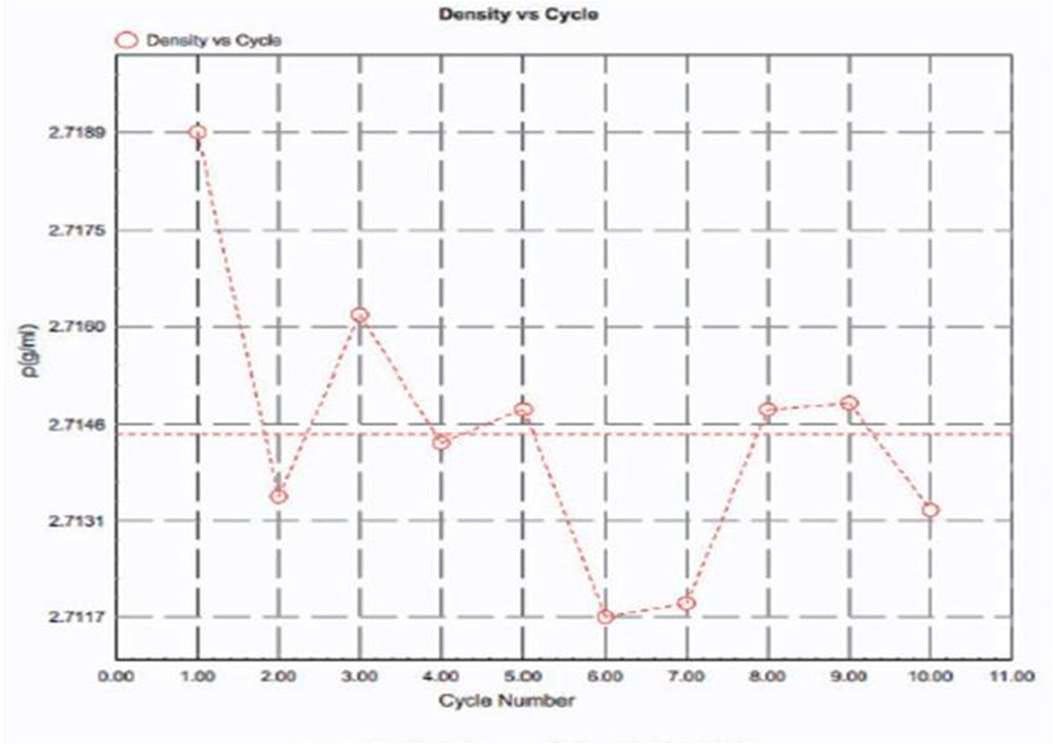

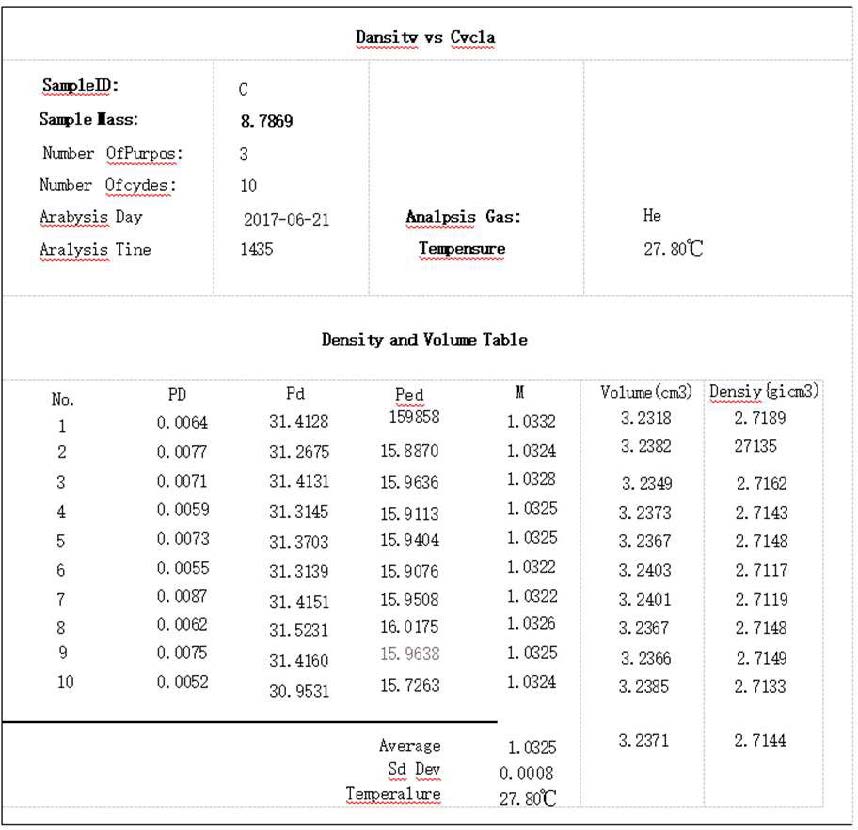

- High Sensitivity & Reproducibility

- The AMI-Sync Series delivers precise and reliable surface area and porosity data, with a BET detection limit as low as 0.1 m² absolute and 0.01 m²/g specific. It offers outstanding reproducibility—within 1% on standard reference materials like BAM P115—ensuring confidence in repeated analyses.

- Precision-Engineered Hardware

- Built with stainless steel and vacuum-brazed manifolds, the system features ultra-durable bellows valves rated for over 5 million cycles. Temperature control maintains ±0.05 °C stability, while 32-bit pressure sensors provide high-resolution, accurate data capture.

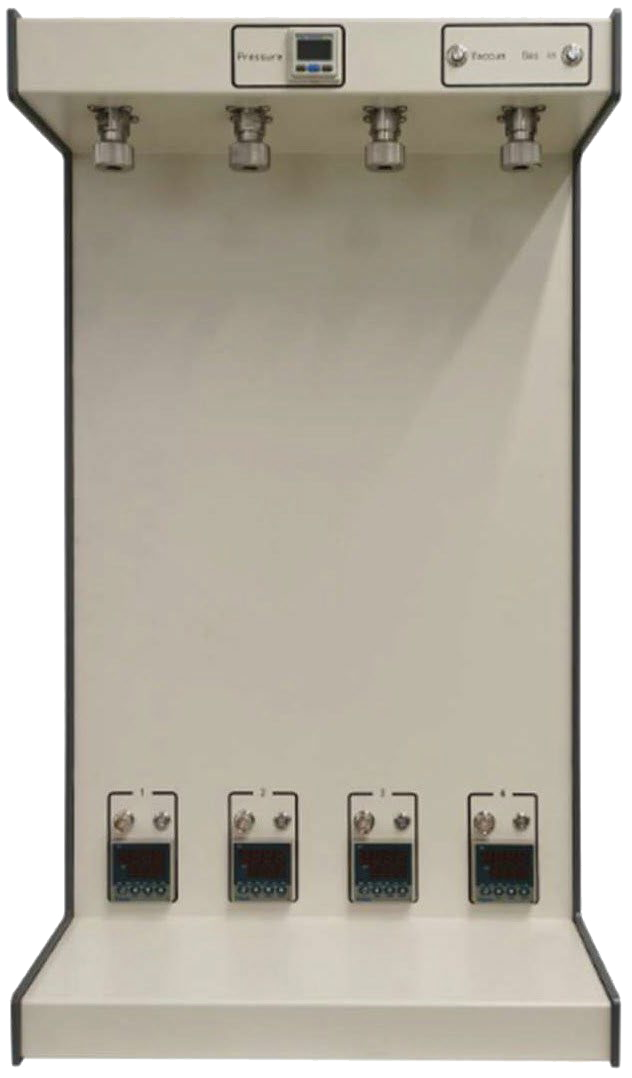

- Cryo TuneTM (Optional Feature)

- Unlock advanced temperature control with Cryo TuneTM, an optional low-temperature cold bath system designed for precision adsorption studies. Fully integrated with Sync software, Cryo TuneTM allows users to effortlessly conduct adsorption isotherm measurements across a range of temperatures.

- Optimized Manifold Contamination Control

- A two-step filtration system protects the manifold from particulates reducing contamination risks and extending instrument life. Combined with stainless steel construction and high-cycle bellows valves, the system ensures clean, reliable operation even in high-throughput environments.

- Compact & Lab-Ready

- All models share a compact footprint of 51 ×53 × 93 cm, making them ideal for space-conscious labs. Despite their compact size, Sync analyzers are fully equipped for both research-grade and industrial applications, offering power, durability, and precision in one system.

SOFTWARE

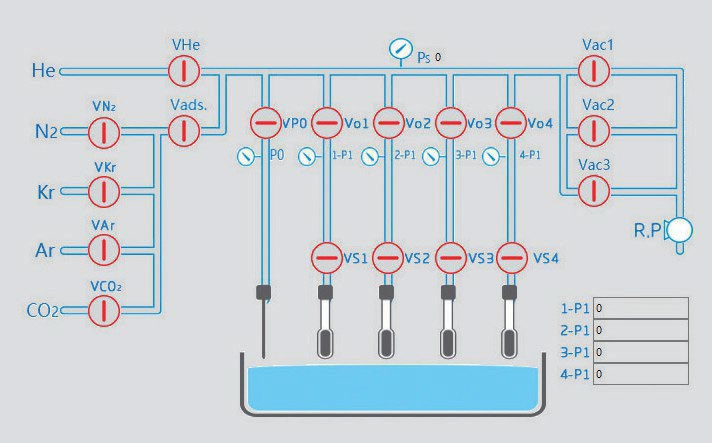

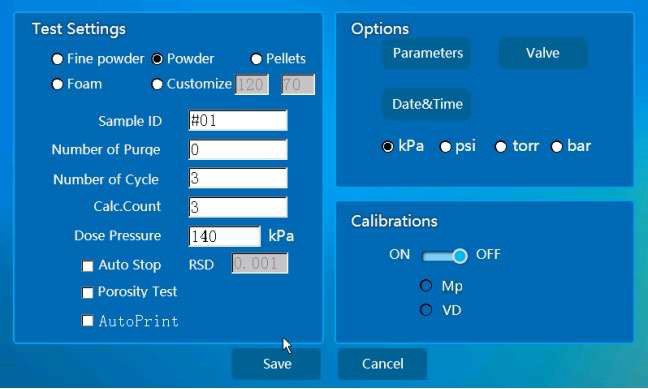

- Sync Series analyzers are driven by a multilingual, user-friendly software suite that supports:

- • Control of up to 8 instruments from a single PC

• Built-in method libraries for fast setup and repeatability

• Customizable analysis profiles with real-time system feedback

• Automated leak detection and guided maintenance routines

• CFR 21 Part 11-ready sample tracking, including ID and method history

• Visual instrument status interface for monitoring analysis in progress - Additional capabilities include void volume correction, supercritical P0 handling, temperature control with CryoTune, and compatibility with up to 6 gases per station.

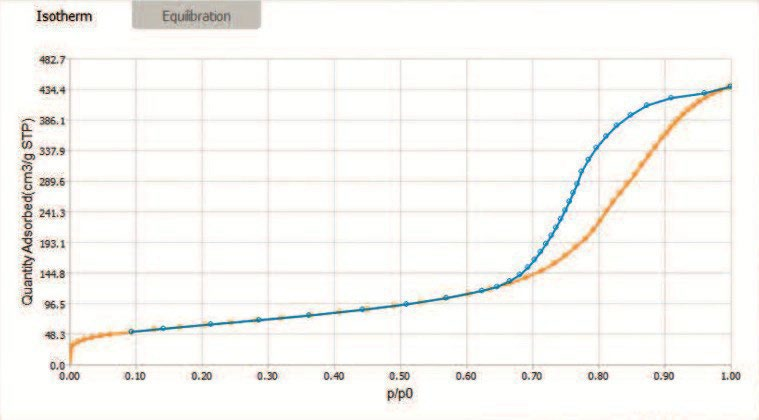

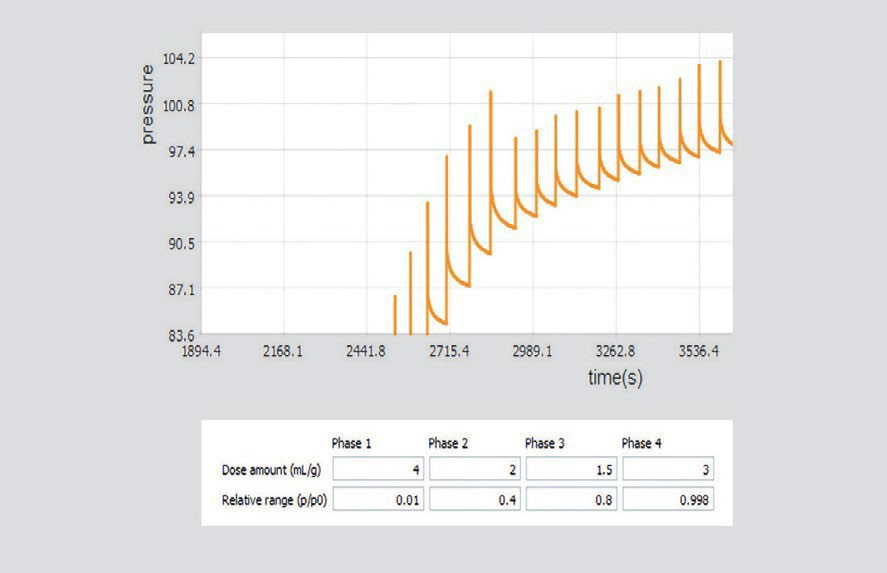

- Isotherm

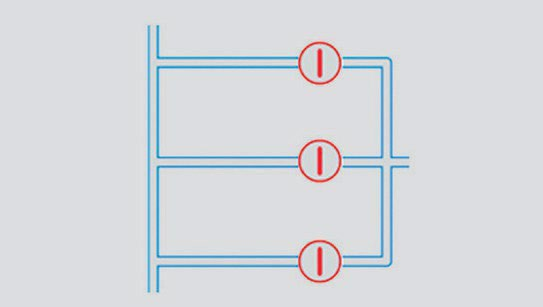

- 3-stage evacuation to prevent sample fluidization

- Main software screen

- Interactive software screen

- Data Analysis Capabilities:

- Isothermal absorption and desorption curve

BET specific surface area (single and multiple point)

Langmuir surface area

Statistical thickness surface area. (STSA)

- HK pore size analysis

SF pore size analysis

NLDFT pore size distribution

Total pore volume

t-plot analysis

SPECIFICATIONS

| Model | AMI-Sync | ||||

| Specific Model | 110 | 210 | 220 | 420 | 440 |

| Analysis Ports | 1 | 2 | 2 | 4 | 4 |

| p0 Transducer | 1 | 1 | 1 | 1 | 1 |

| Analysis Pressure Transducer | 1 | 1 | 2 | 2 | 4 |

| Surface Area | ≥ 0.0005 m2/g | ||||

| Pore Size | 0.35-500 nm | ||||

| Pore Volume | ≥ 0.0001 cm3 /g | ||||

| Pump | Mechanical pump(minimal 5.0×10-4 mmHg) | ||||

| p/p0 | 10-5-0.998 | ||||

| Accuracy PTs | 1000 mmHg(+/-0.2%F.S.) | ||||

| Adsorbates | N2,CO2,Ar,Kr,H2,O2,CO,NH3,CH4 | ||||

| Dimensions | 51 × 53 ×93 cm (16.1 x 20.8 x 36.6 inches) All same dimensional size | ||||

| Weight | 45 kg | 99 pounds (maximum depending on configuration) | ||||

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com