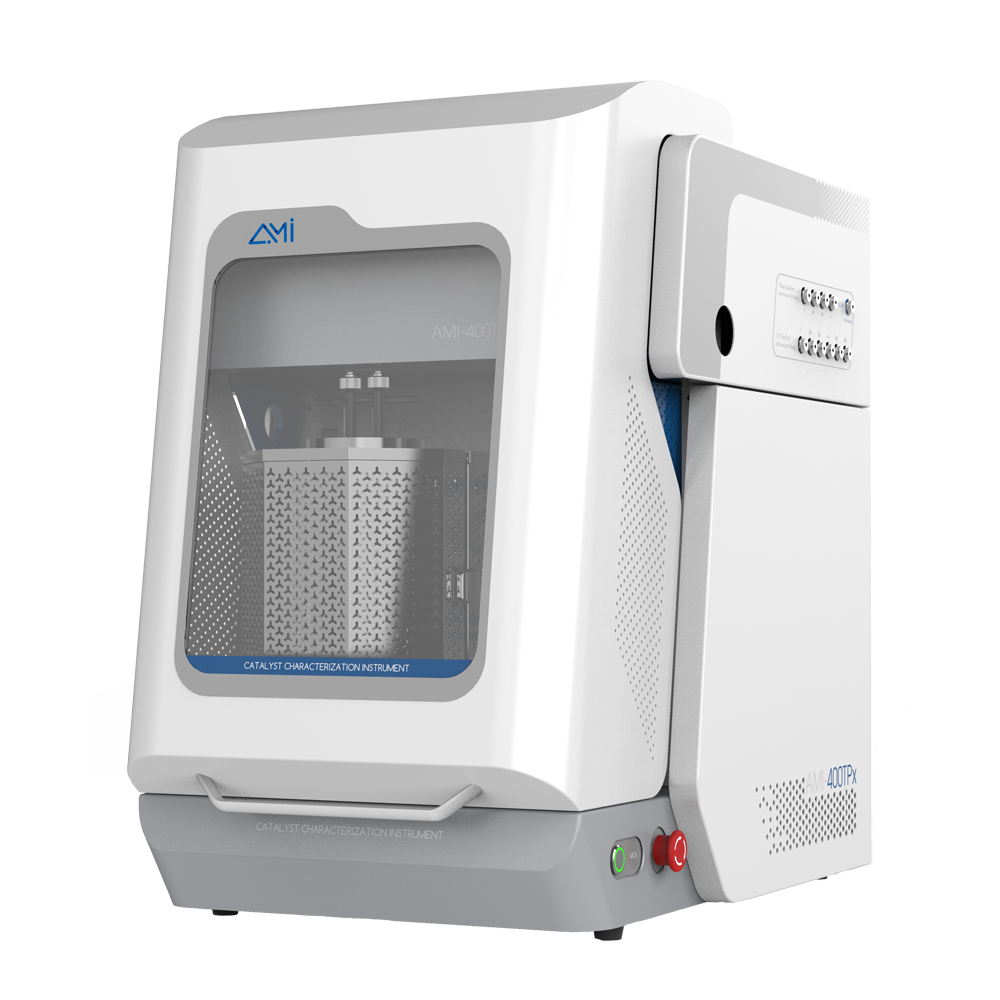

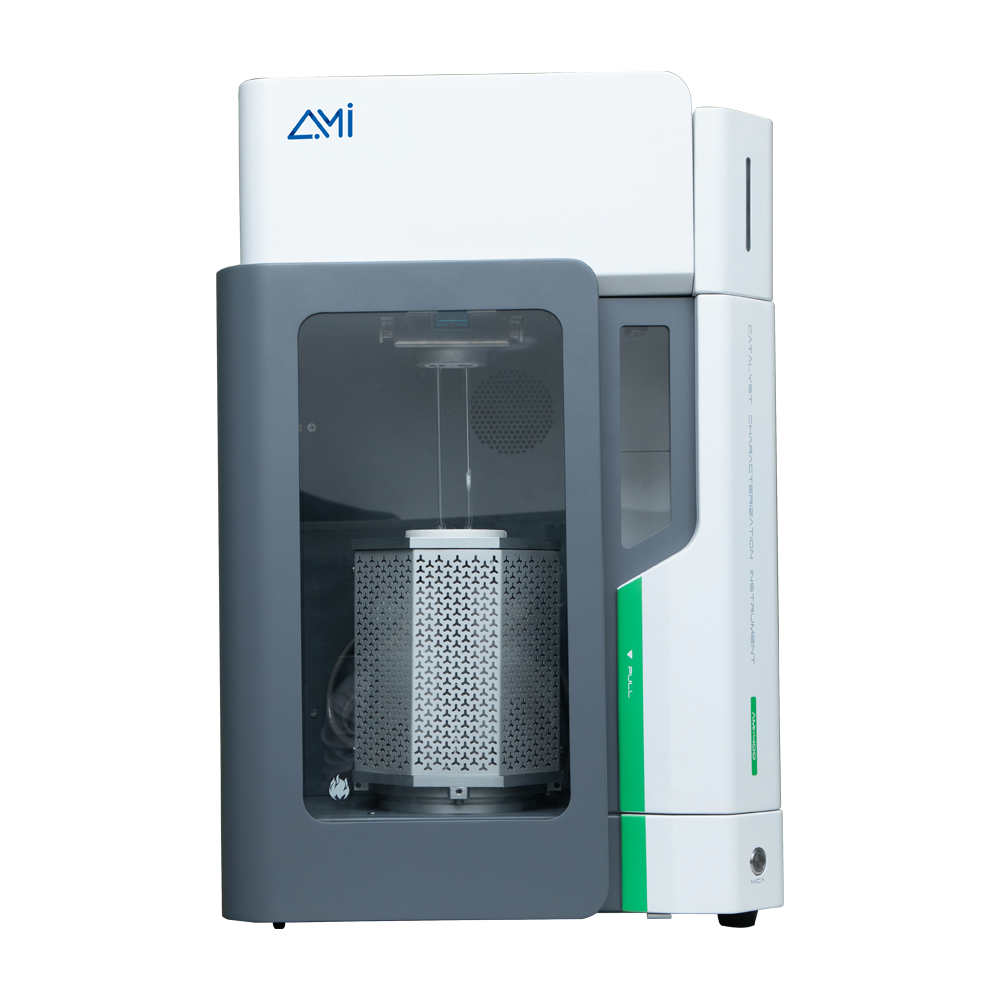

AMI 400TPx

INTRODUCTION

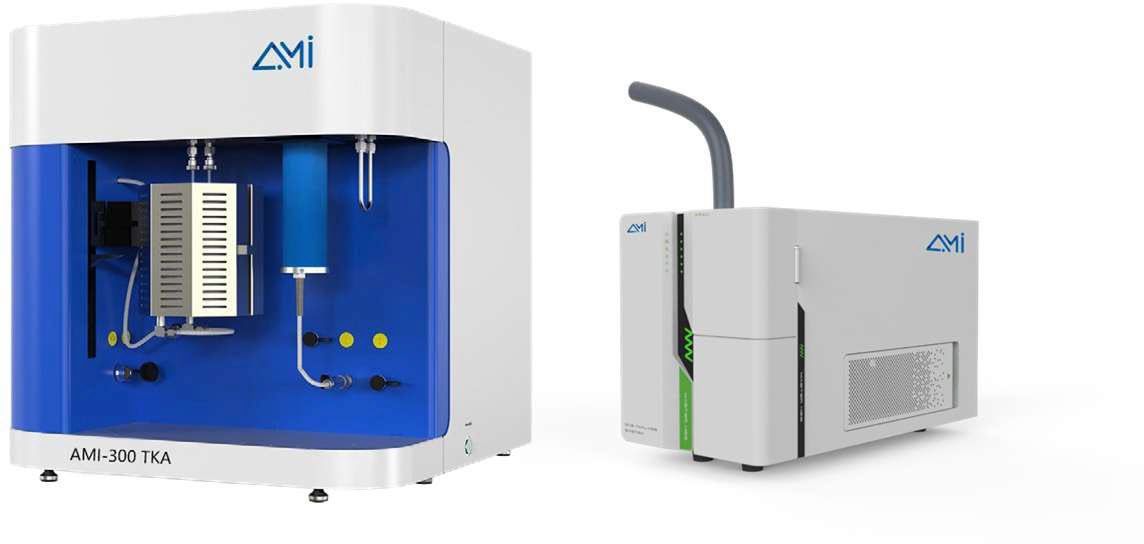

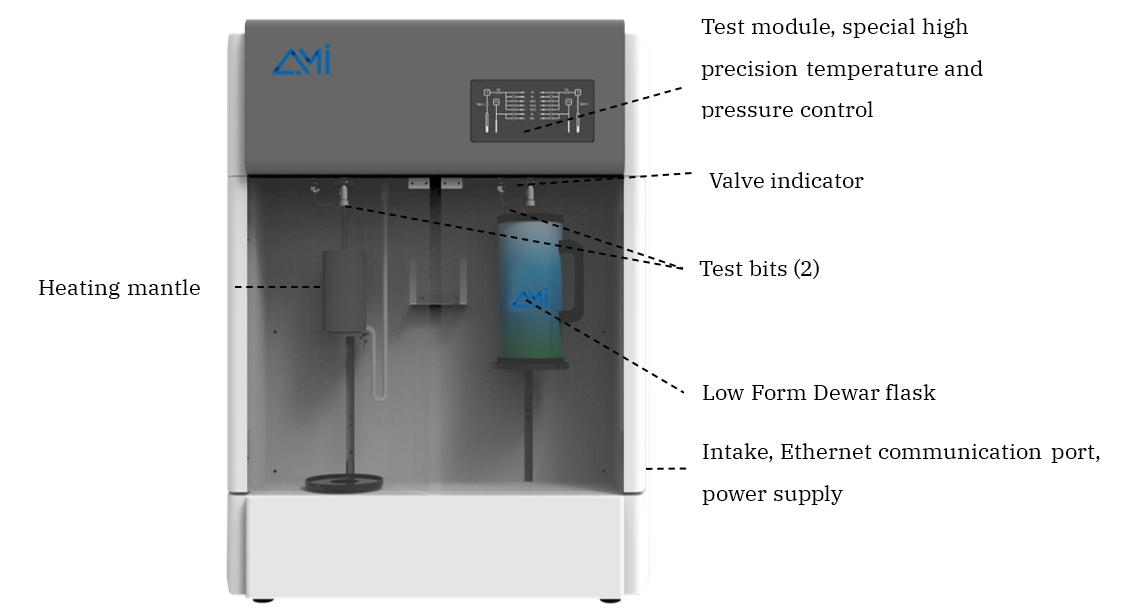

- The AMI-400TPx sets a new benchmark in fully automated chemisorption analysis, combining advanced capabilities with outstanding economic efficiency. Designed with unattended operation at its core, it addresses the high standards and evolving needs of catalyst researchers while minimizing operating costs and maximizing laboratory productivity.

- This space-saving system is equipped with robust control components and advanced data processing software, enabling the delivery of accurate kinetic parameters critical for catalyst characterization. Its compact, cost-effective design makes it an ideal choice for labs with limited space or budget, without compromising analytical performance.

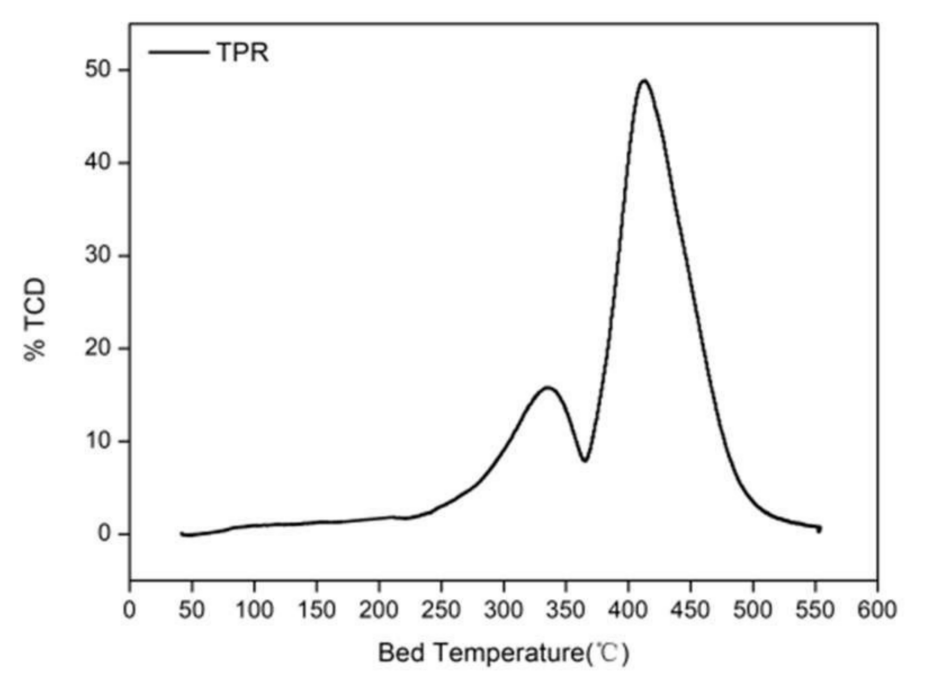

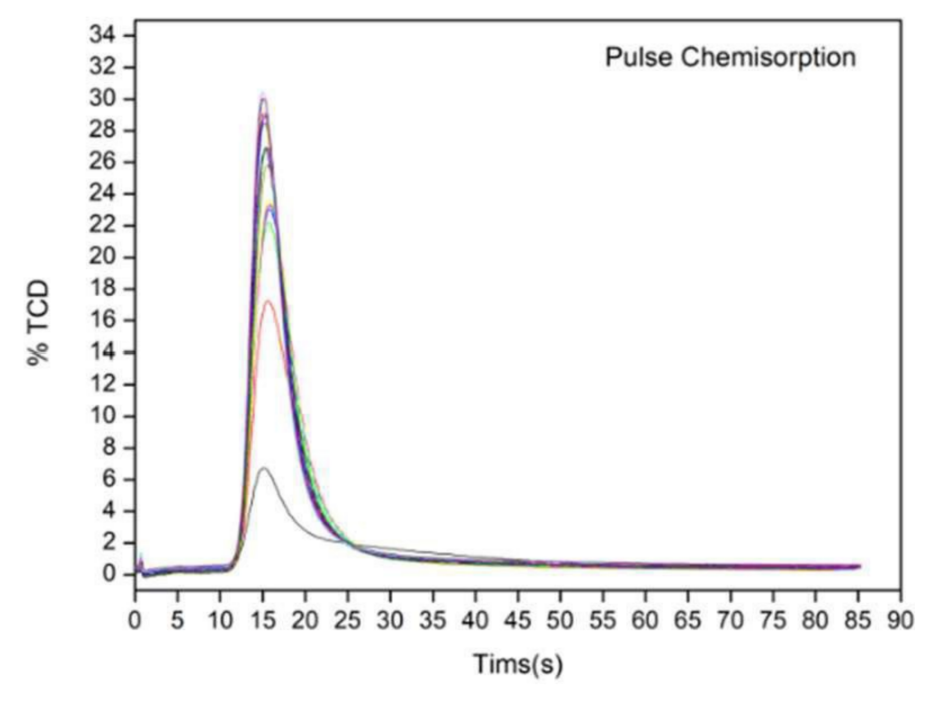

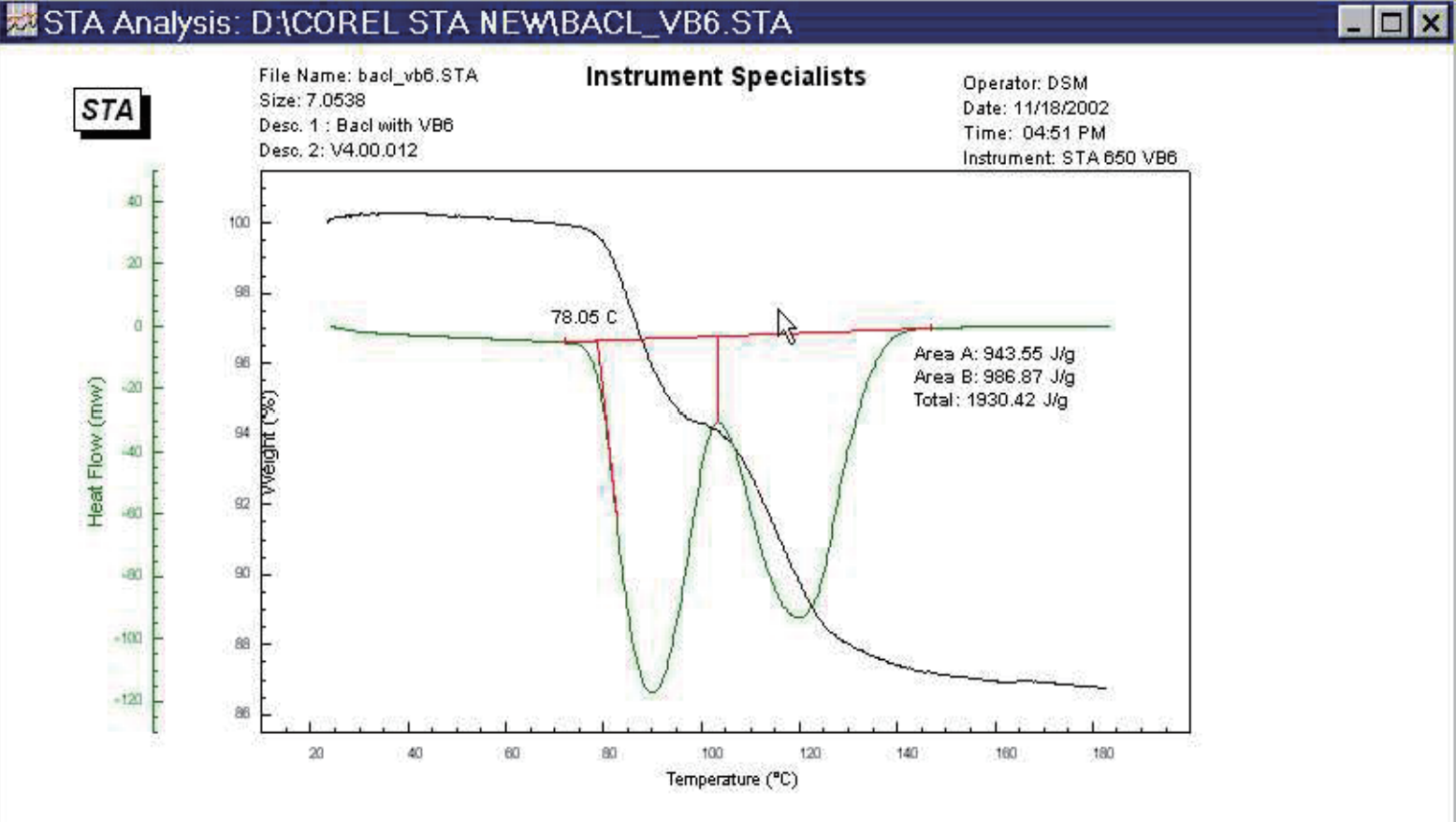

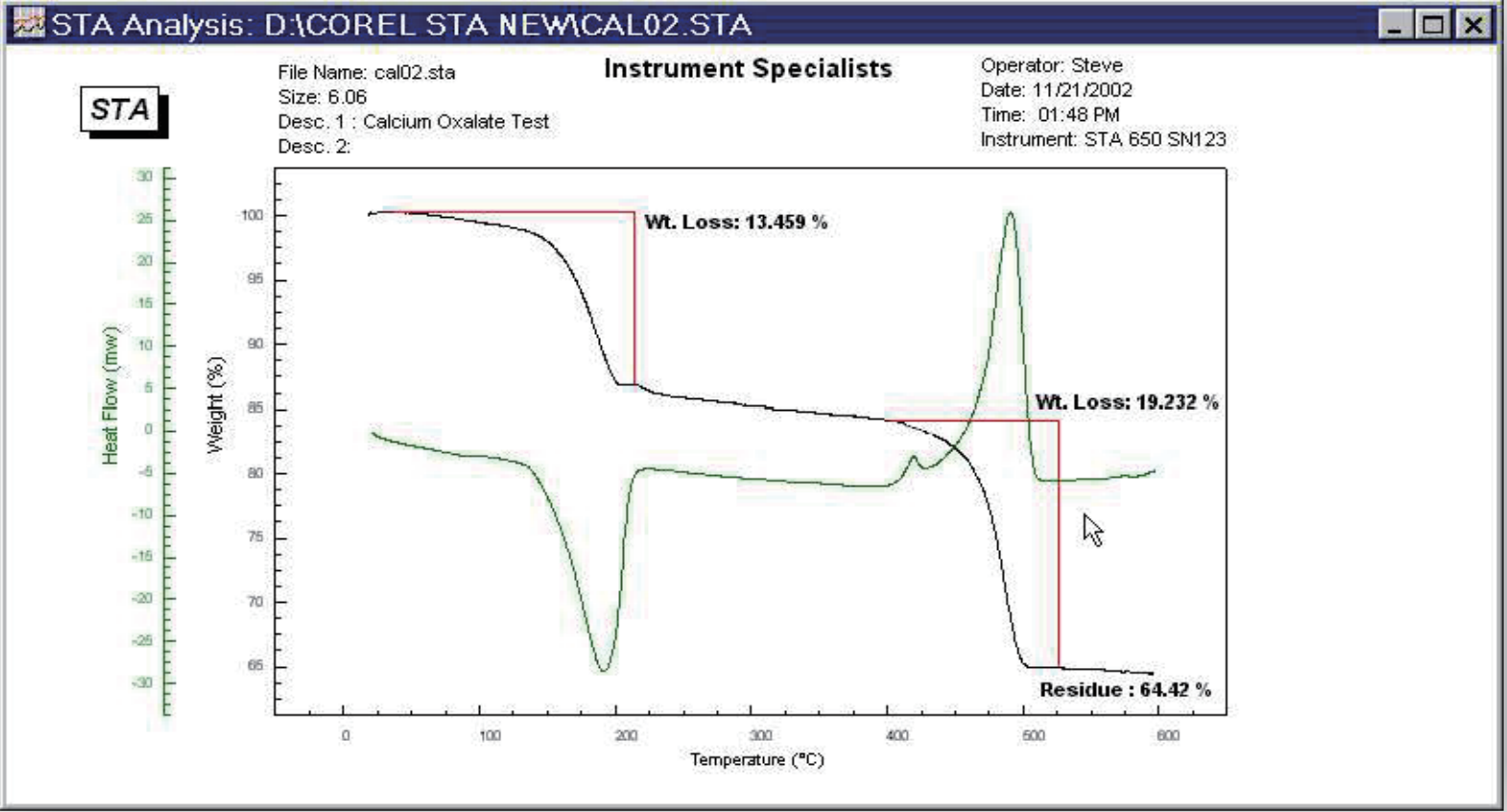

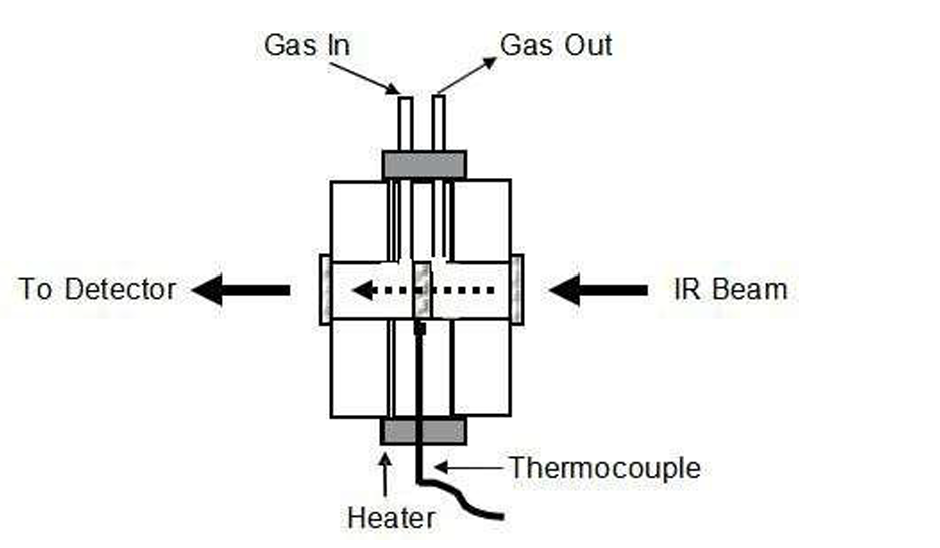

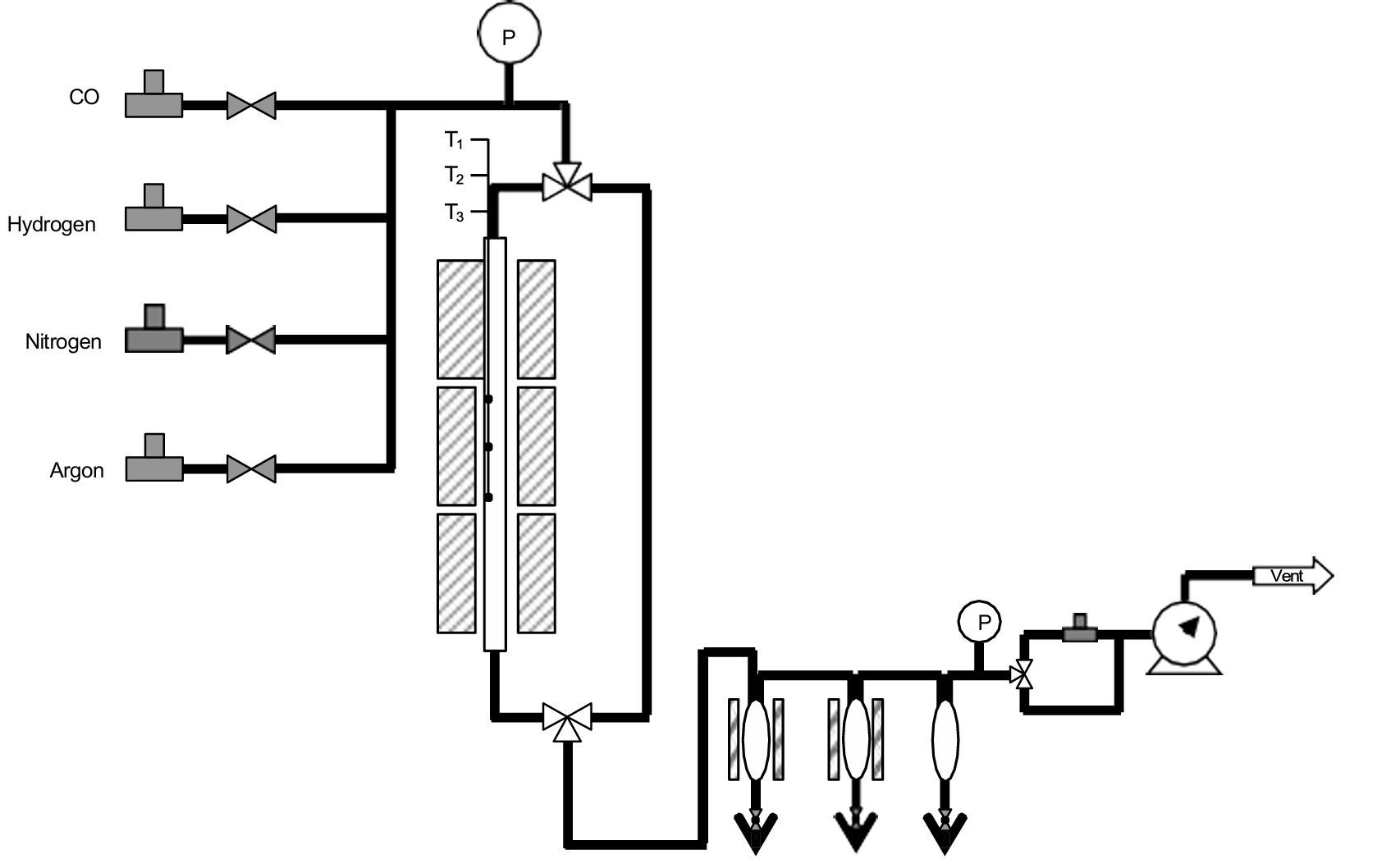

- The AMI-400TPx comes standard with temperature-programmed desorption (TPD), temperature-programmed reduction and oxidation (TPR/O), and temperature-programmed surface reaction (TPSR) capabilities. For laboratories with more advanced requirements, optional features include pulse chemisorption, a sub-ambient temperature module, a mass spectrometer for evolved gas analysis, and a gas chromatograph for detailed component separation and quantification. This flexibility allows users to tailor the system to their specific research goals while maintaining a practical, affordable approach to catalyst evaluation.

- ✔ Temperature-programmed desorption (TPD)

✔ Temperature-programmed reduction/oxidation (TPR/O)

✔ Temperature-programmed surface reaction (TPSR)

Options:

✔ Pulse chemisorption

✔ Sub-ambient module

✔ Mass spectrometer

✔ Gas chromatograph

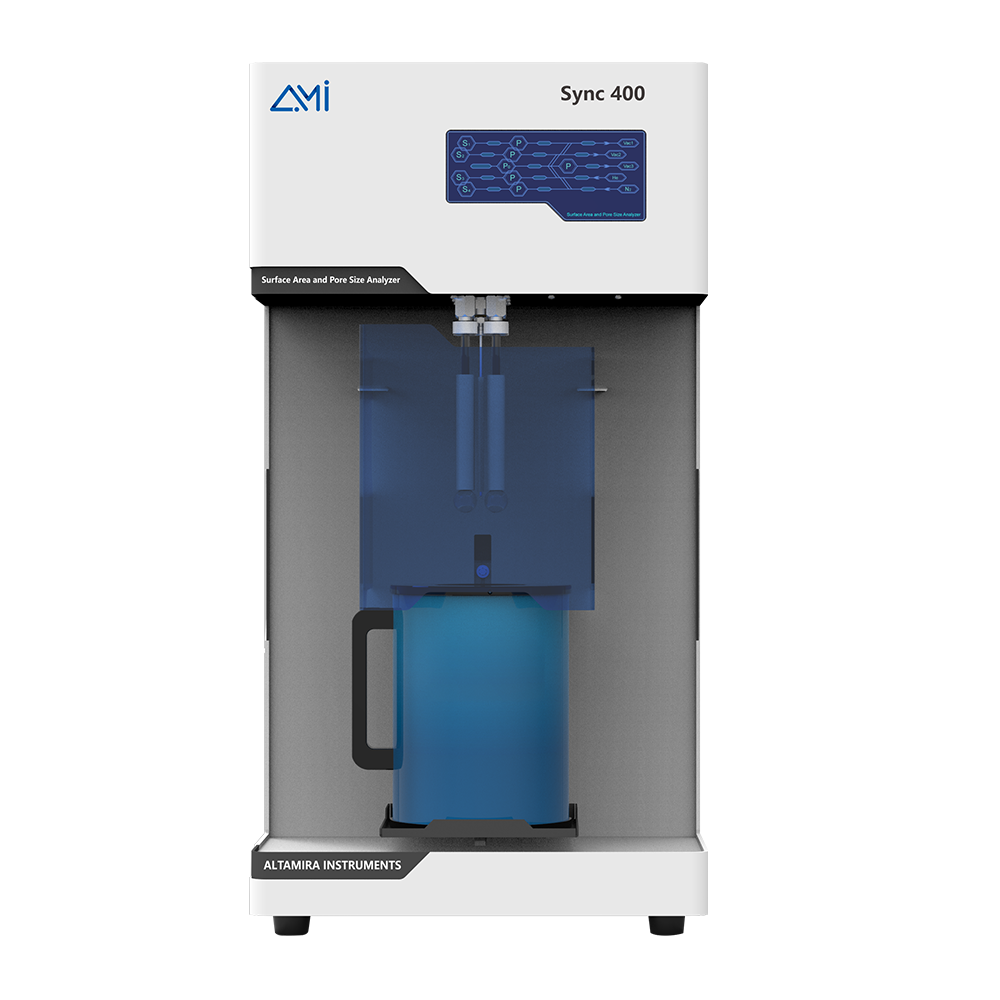

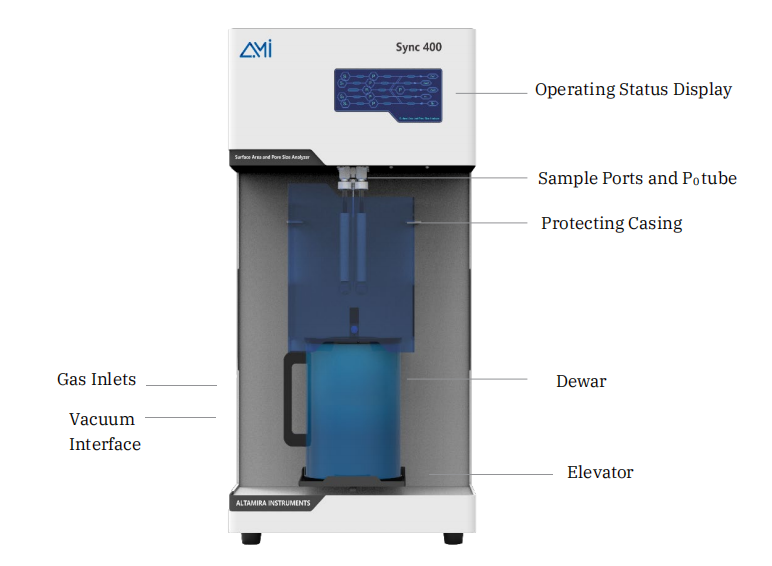

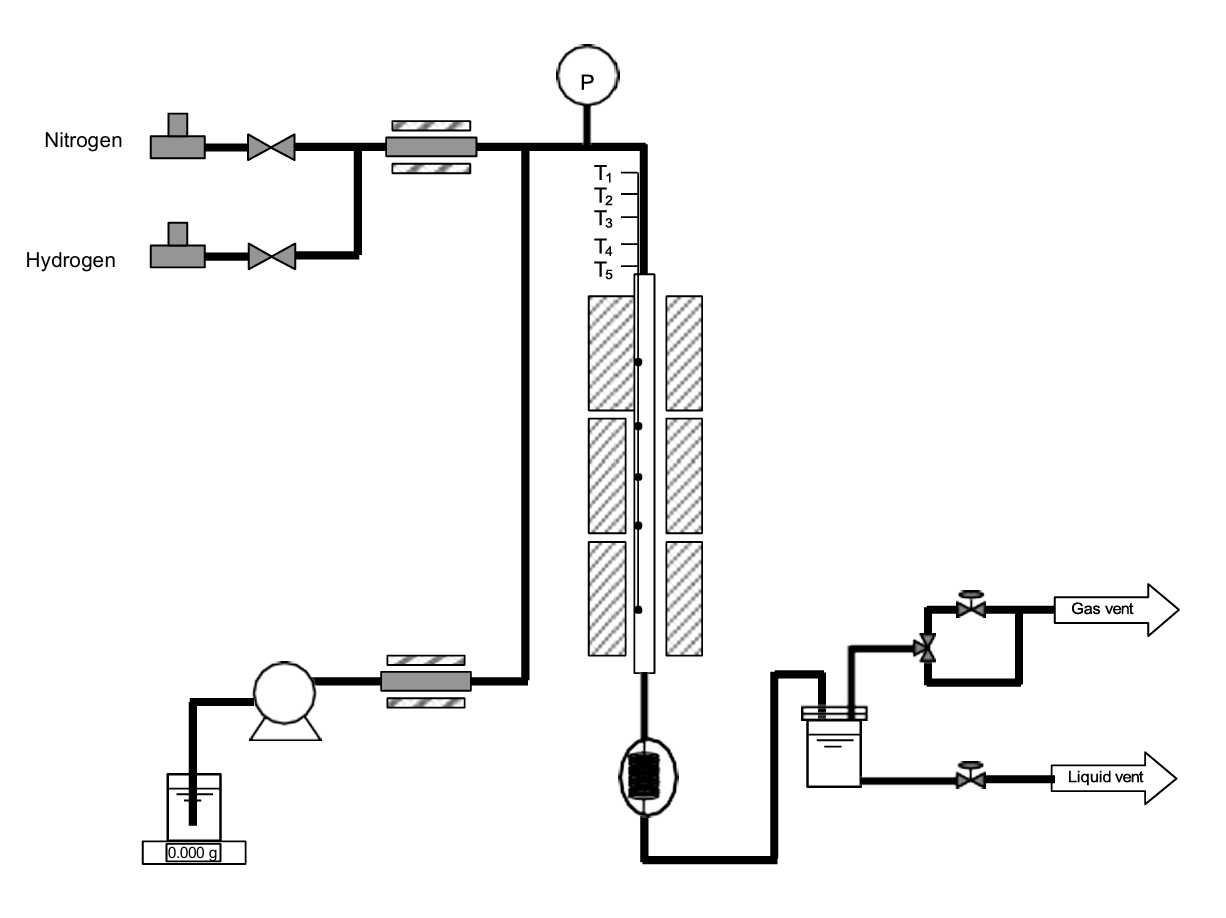

- AMI-400TPx chemisorption analyzer

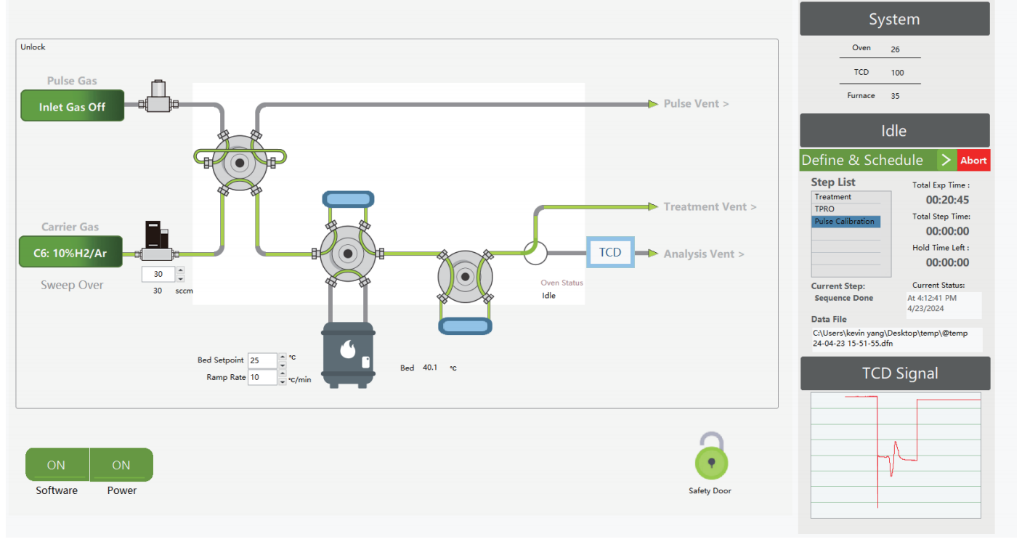

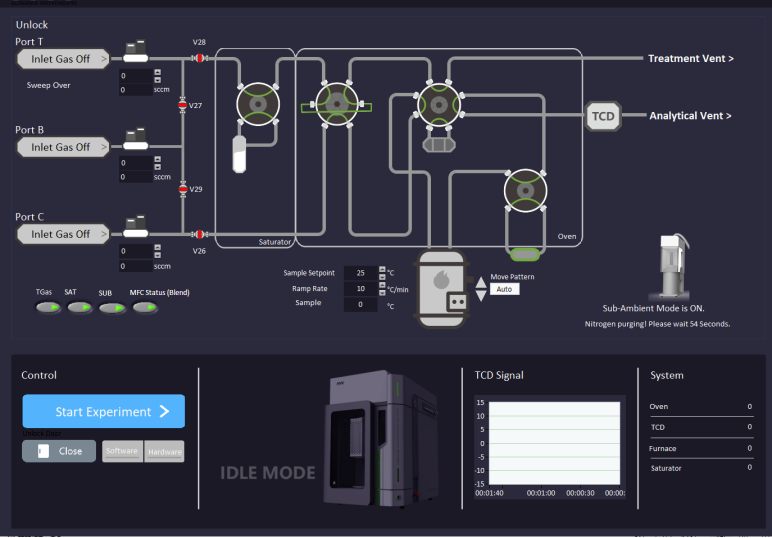

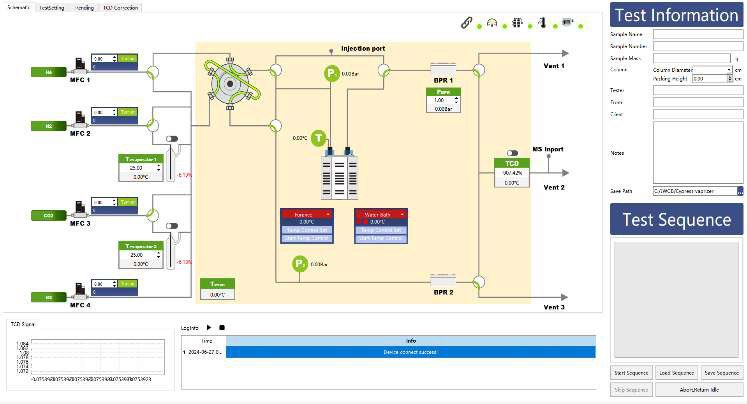

SOFTWARE

- One of the key advantages of the AMI-400TPx is its ability to operate without constant operator supervision, making it an ideal solution for busy research environments. Once the experiment is set up and running, the system performs fully automated sequences, freeing up valuable time for researchers to focus on data analysis, planning, or other laboratory activities.

- The instrument is designed to run on a standard Windows-based computer, providing a familiar and user-friendly interface. It also supports Internet connectivity, enabling remote monitoring and control when needed. This flexibility ensures that the AMI-400TPx can be easily integrated into the existing digital infrastructure of any laboratory.

- Moreover, the same computer used to control the instrument can be utilized to manage additional laboratory tasks, streamlining operations and reducing the need for multiple workstations. This combination of automation, connectivity, and multitasking capability makes the AMI-400TPx a powerful and practical tool for modern catalyst research laboratories.

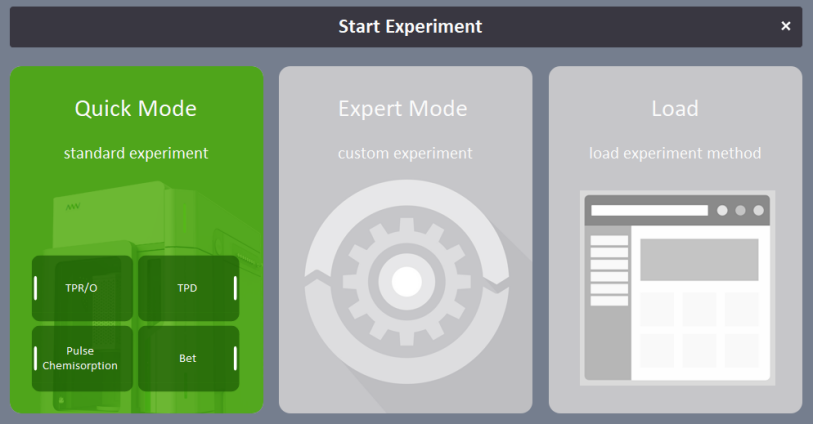

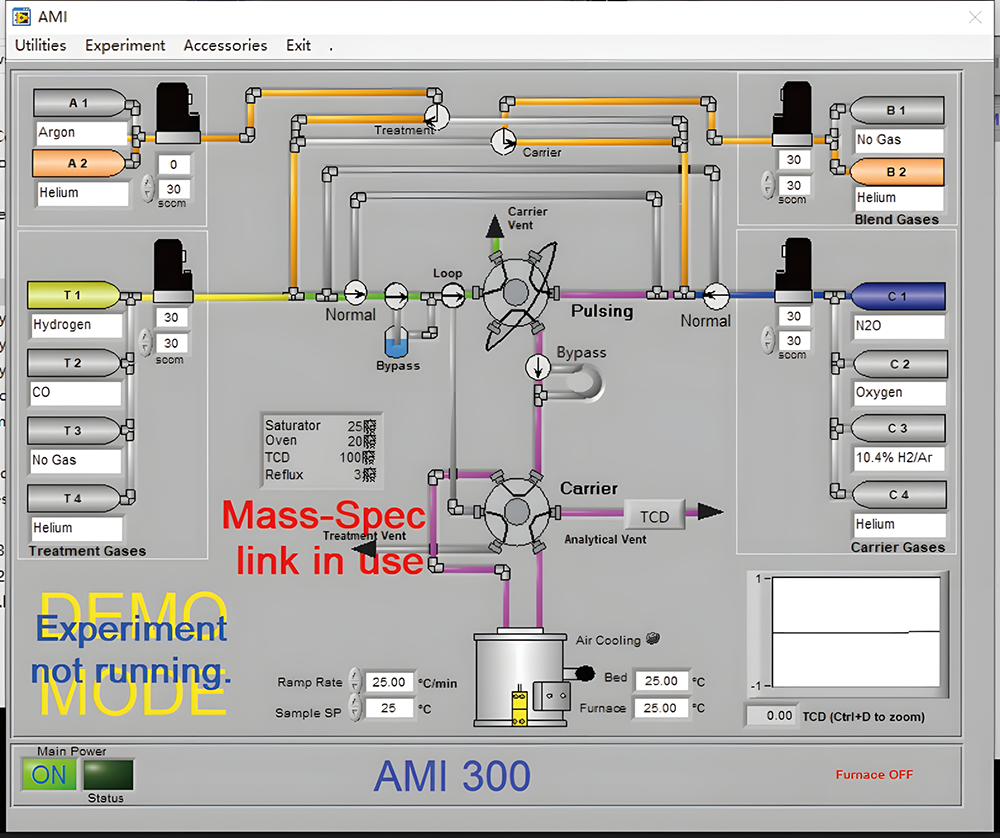

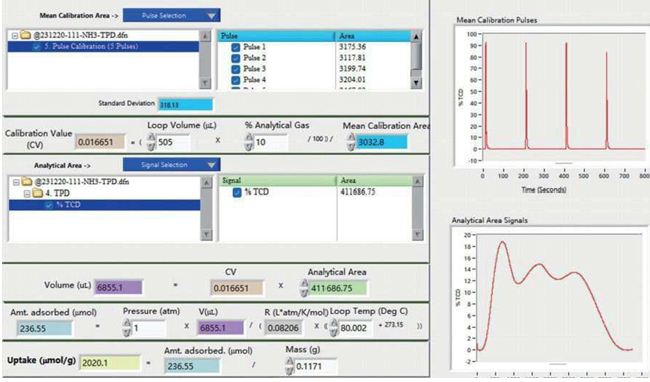

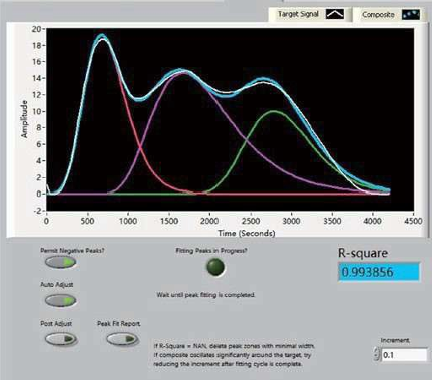

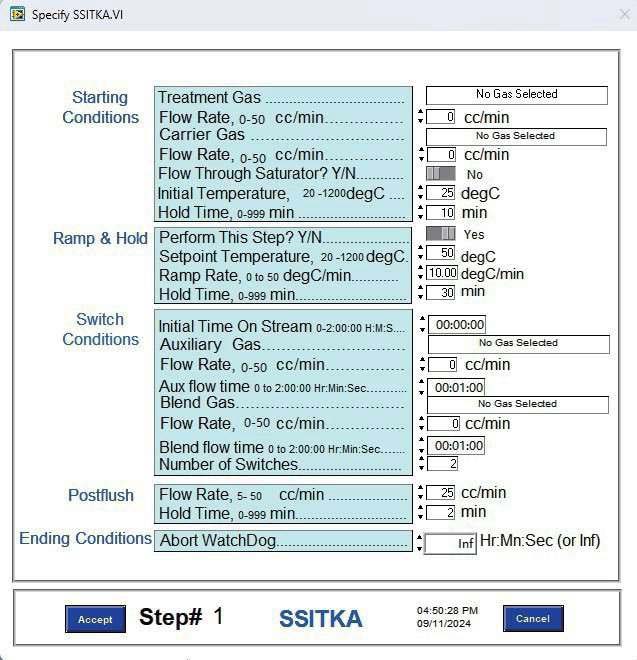

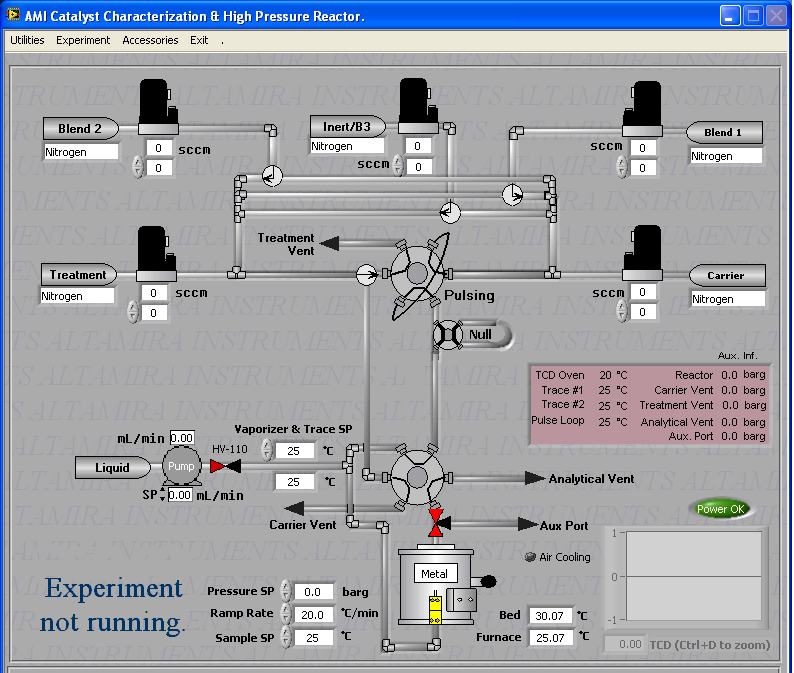

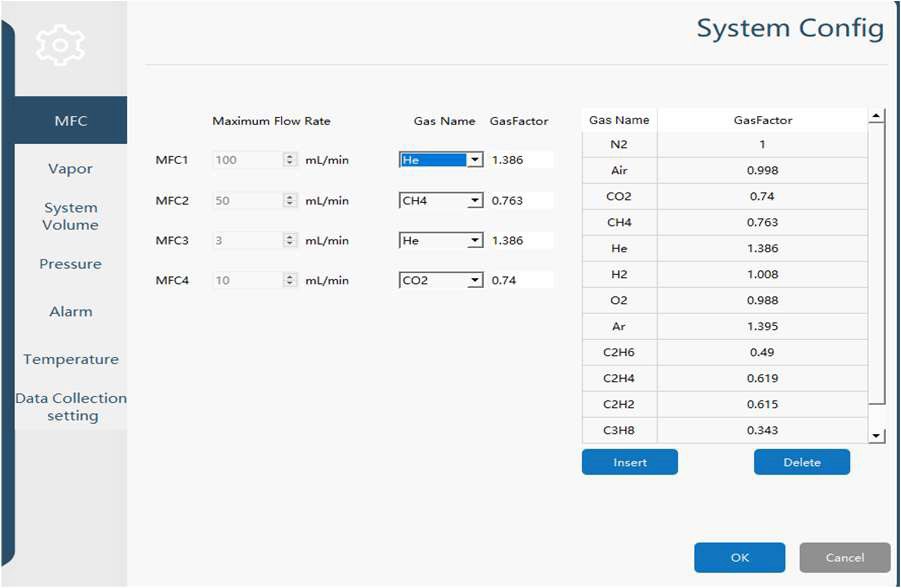

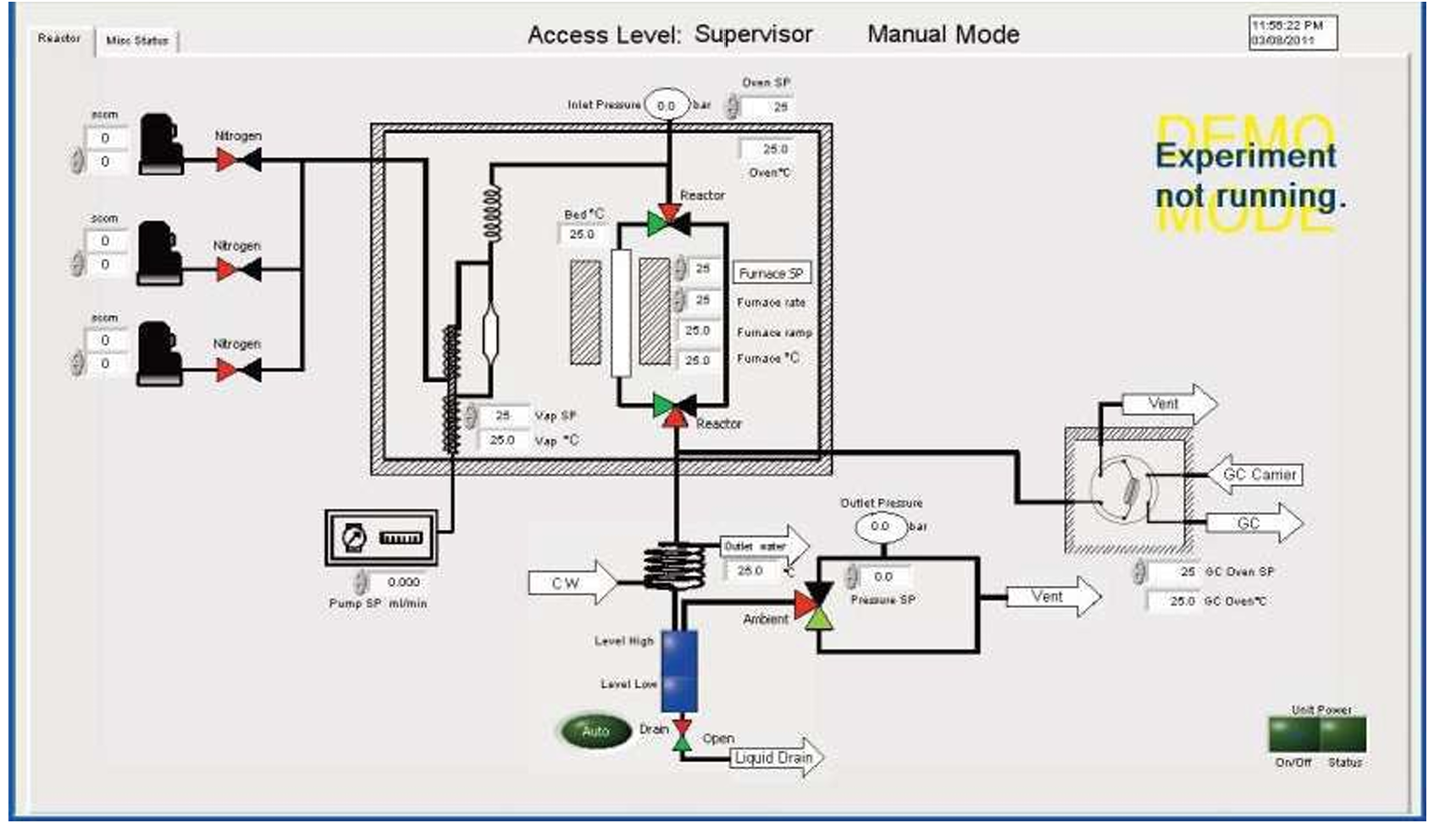

- AMI-400TPx operation interface

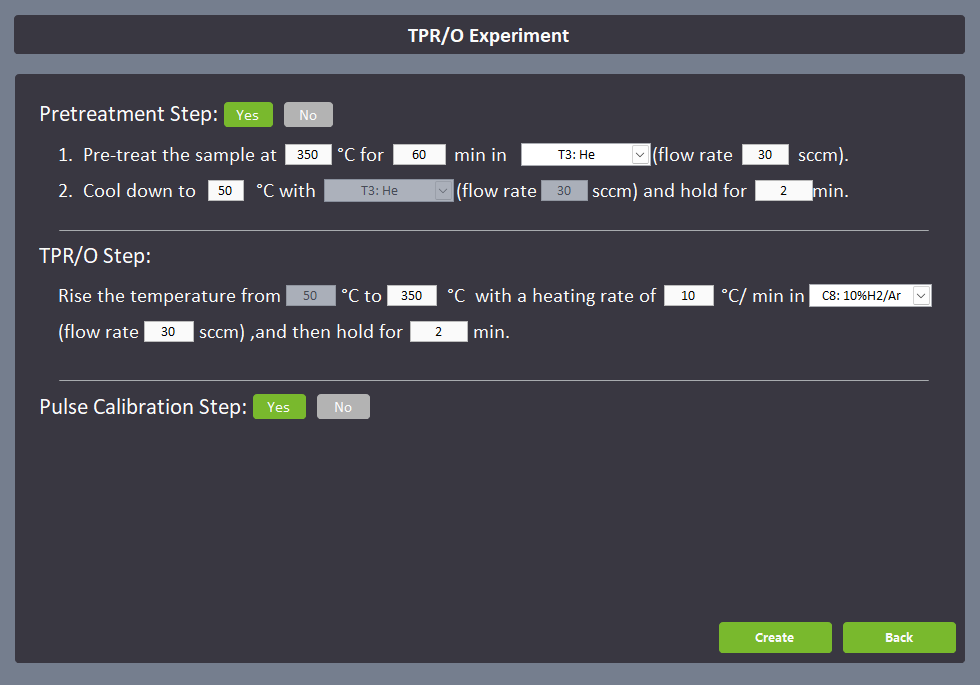

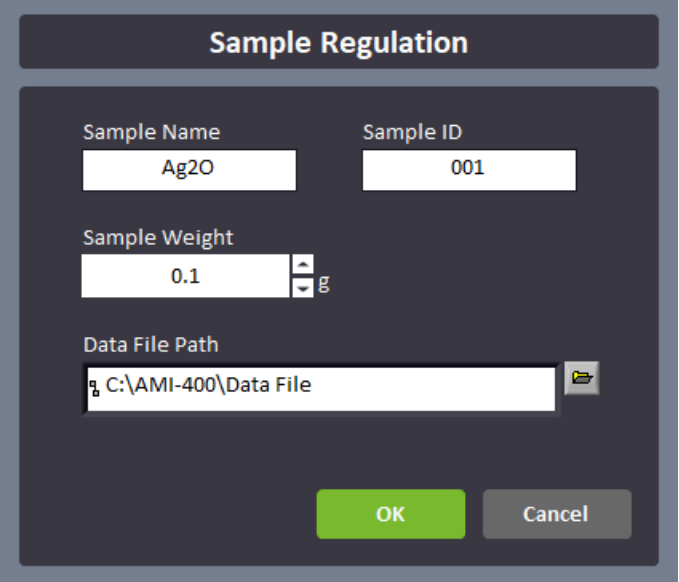

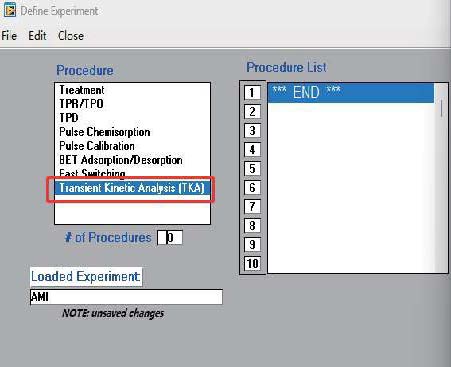

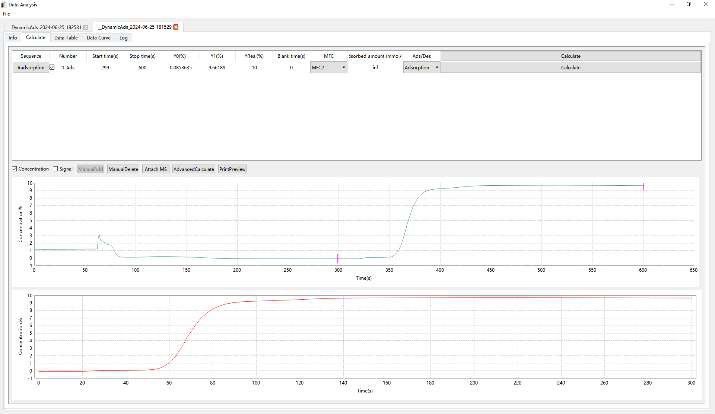

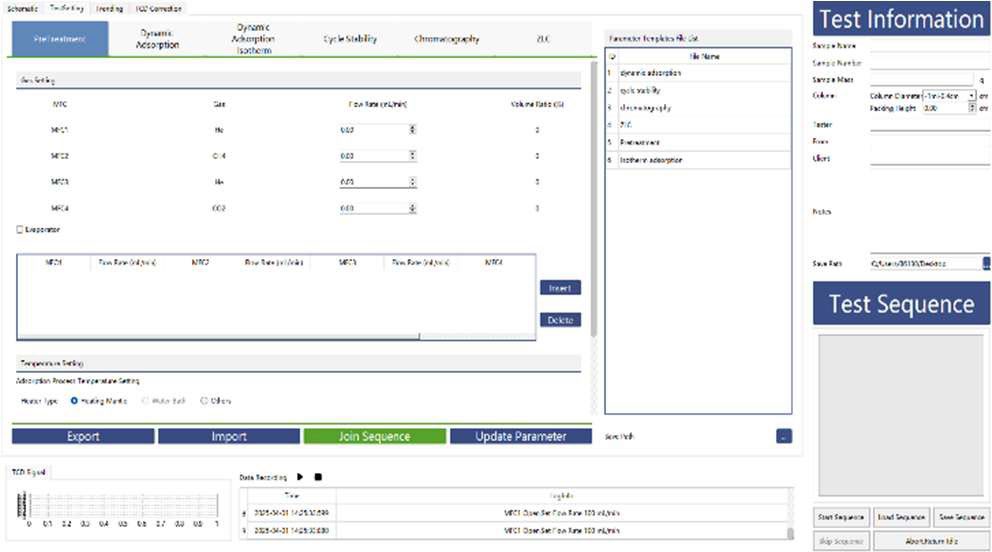

- The AMI-400TPx features a user-friendly interface and intuitive layout that simplifies experimental design. Users need only to input the changeable process variables, while the system automatically handles the rest—making setup quick and error-free. Flexible selection or customization of methods such as TPD, TPO, TPR, TPSR, and pulse calibration is supported, with the ability to configure up to 99 fully automated programs. A complete experiment can be set up in just a few minutes, streamlining workflows and boosting lab productivity.

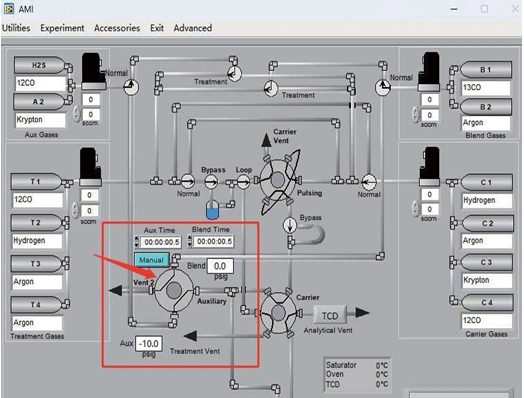

- AMI-400TPx experiment setting interface

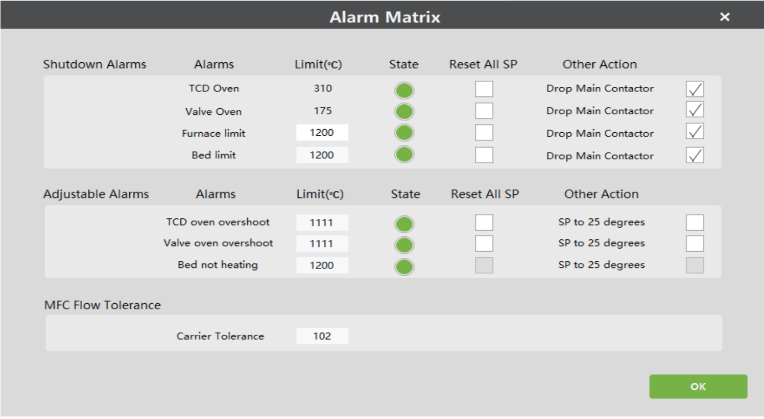

- The AMI-400TPx is equipped with a multi-layered safety system that combines hardware, firmware, and software safeguards to ensure reliable and secure operation. On the hardware side, a temperature safety switch provides immediate protection against furnace overheating. Built-in firmware-level factory-set alarms offer an additional layer of control to prevent unsafe operating conditions. At the software level, an intuitive interface allows users to configure a wide range of safety protection programs, including automated alarms, manual valve control, and real-time input of gas flow and temperature settings. Together, these features deliver robust, comprehensive protection throughout every stage of operation.

- AMI-400TPx alarms setting interface

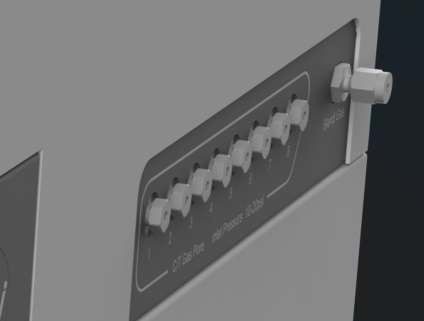

PARAMETERS

-

AMI-400TPx Number of Stations< 1 Temperature range -100°C(optional)-1200°℃ Mass flow controller 1 Temperature ramp rates 0.1 - 50 ℃/min Gas inlets 6 analysis ports, 4 pulse port Operating Pressure Atmospheric pressure Gas flow rate 2-100 sccm Sample tube Quartz U-shaped tube, bubble tube

TCD detector Tungsten-rhenium filament Process Tubing 316L Stainless Steel, 1/16 inch Seals Viton, Buna-N,Kalrez,etc Dimensions L 17.0 in (43 cm) x W 25.2 in (64 cm) × H 24.5 in (62 cm)

Products

Products

Products

Products

-1.png)

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com