Prep Series

Prep 8A- VACUUM DEGASSER

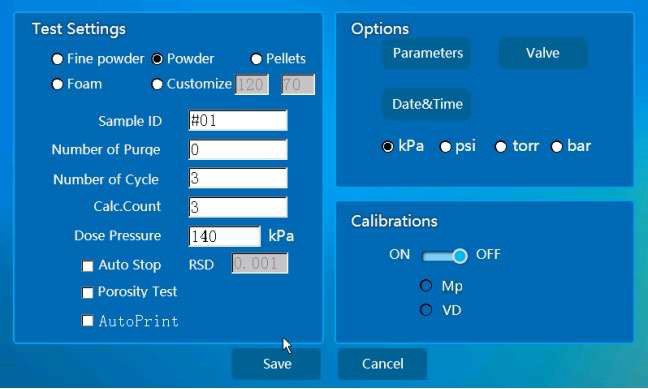

- The Prep 8A features two independent working modules, each with four degassing ports, allowing simultaneous preparation of up to eight samples. Each module operates with independent temperature and time controls, enabling flexible and parallel sample degassing.

- A multi-stage vacuum pumping system, regulated by an internal pressure transducer, prevents sample elutriation, controls switching pressure, regulates nitrogen backfill pressure, and maintains precise pressure control during furnace descent. Programmable temperature ramping and a built-in cooling fan ensure efficient, precise, and controlled thermal treatment.

- The system is operated via a 7-inch touchscreen interface with automatic parameter memory, streamlining operation and enhancing usability.

- Use-Case:

- High-capacity vacuum degasser with vertical configuration; ideal for labs prioritizing throughput, thermal uniformity, and complete automation.

- Prep 8A

-

Model Prep 8A Temperature RT-400°C Control accuracy

±1°C Degassing port 8 Pump 1 mechanical pump Heating method Programmed temperature ramping (Optional) Dimensions and weight L 17.0 in (430 mm)

W 16.0 in (405 mm)

H 28.5 in (725 mm)

80 lbs (36 kg)

Prep 8M-VACUUMDEGASSER

- Prep 8M

- ThePrep 8M vacuum degasser features a single working module with eight degassing ports, enabling the simultaneous preparation of up to eight samples under uniform thermal conditions. All stations operate at the same temperature, making it ideal for processing multiple samples consistently.

- Designed for efficiency and ease of use, the Prep 8M allows quick disassembly of sample tubes, supports grouped programmed temperature ramping,and features a purge-assisted cooling function for rapid cooldown. Its anti-elutriation design ensures sample integrity throughout the vacuum degassing process.

- Temperature is fully programmable to deliver consistent and precise thermal treatment, while vacuum and backfill are manually controlled, giving operators the flexibility to manage timing and sequencing based on specific sample requirements

- Use-Case:

- Compact benchtop vacuum degasser with semi-automated functionality suited for space-constrained labs needing 8-port capacity.

-

Model Prep 8M Temperature RT-400°C Control accuracy

±1°C Degassing port 8 Pump 1 mechanical pump Heating method Programmed Dimensions and weight L 15.5 in (395 mm)

W 18.0 in (455 mm)

H 14.0 in (358 mm)

66 lbs (30 kg)

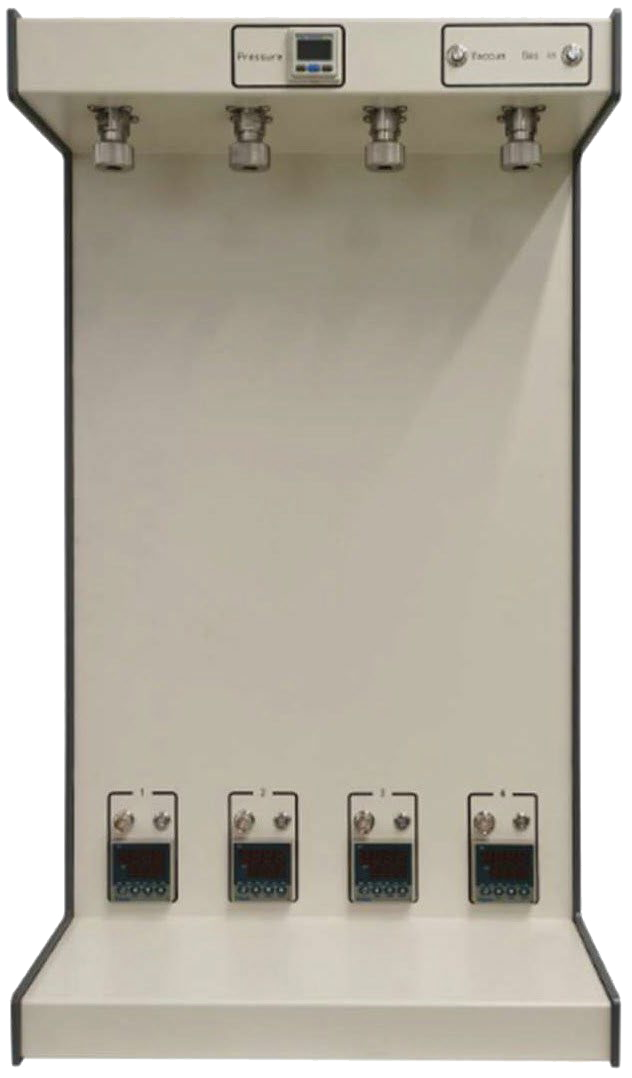

Prep 4M-VACUUM DEGASSER

- ThePrep 4M vacuum degasser features four independent degassing stations, each with individually adjustable temperature and time parameters. This allows for the simultaneous preparation of multiple samples under different conditions, making it ideal for laboratories handling diverse materials.

- Designed to maintain sample integrity, the system includes an anti-elutriation design to prevent particle loss during evacuation.It also supports optional programmable temperature ramping for controlled and repeatable heating cycles. Vacuum and nitrogen backfill are manually controlled, giving operators the flexibility to manage process timing based on specific sample requirements.

- ThePrep 4M offers a compact and versatile solution for reliable sample pretreatment in surface area and gas adsorption analyses.

- Use-Case:

- Economical 4-port vacuum degasser for low-to-mid throughput needs; temperature ramping available as an option.

- Prep 4M

-

Model Prep 4M Temperature RT-400°C Control accuracy

±1°C Degassing port 4 Pump 1 mechanical pump

(Ultimate vacuum 10-2 Pa, optional)Heating method Programmed temperature ramping (Optional) Dimensions and weight L 16.0 in (410 mm)

W 14.5 in (361 mm)

H 27.6 in (702 mm)

55 lbs (25 kg)

Prep 8F –FLOW DEGASSER

- Prep 8F

- The Prep 8F is a versatile, high-throughput degassing system featuring two independent working units, each with four degassing ports, allowing the simultaneous preparation of up to eight samples. Each unit offers independent control of degassing temperature and time, providing flexibility for handling different sample types.

- Designed for dynamic(flow) degassing, the system ensures efficient and uniform sample preparation without the use of vacuum. A programmable temperature ramping function enables controlled heating, while a built-in furnace fan facilitates rapid cooling between runs.

- Operation is streamlined through a 7-inch integrated touchscreen with an intuitive interface and automatic parameter memory, making the Prep 8F an ideal solution for high-throughput sample pretreatment in surface area and gas adsorption analysis

- Use-Case:

- Flow-based degasser with 8 ports;designed for applications where vacuum degassing is not preferred or feasible.

-

Model Prep 8F Temperature RT-400°C Control accuracy

±1°C Degassing port 8 Pump 1 mechanical pump Heating method Programmed temperature ramping (Optional) Dimensions and weight L 27.0 in (680 mm)

W 16.0 in (404 mm)

H 15.7 in (400 mm)

70 lbs (32 kg)

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com