| Vapor Series |

| Specific Model |

Vapor 100B |

Vapor 200B |

Vapor 200C |

| Analysis Ports |

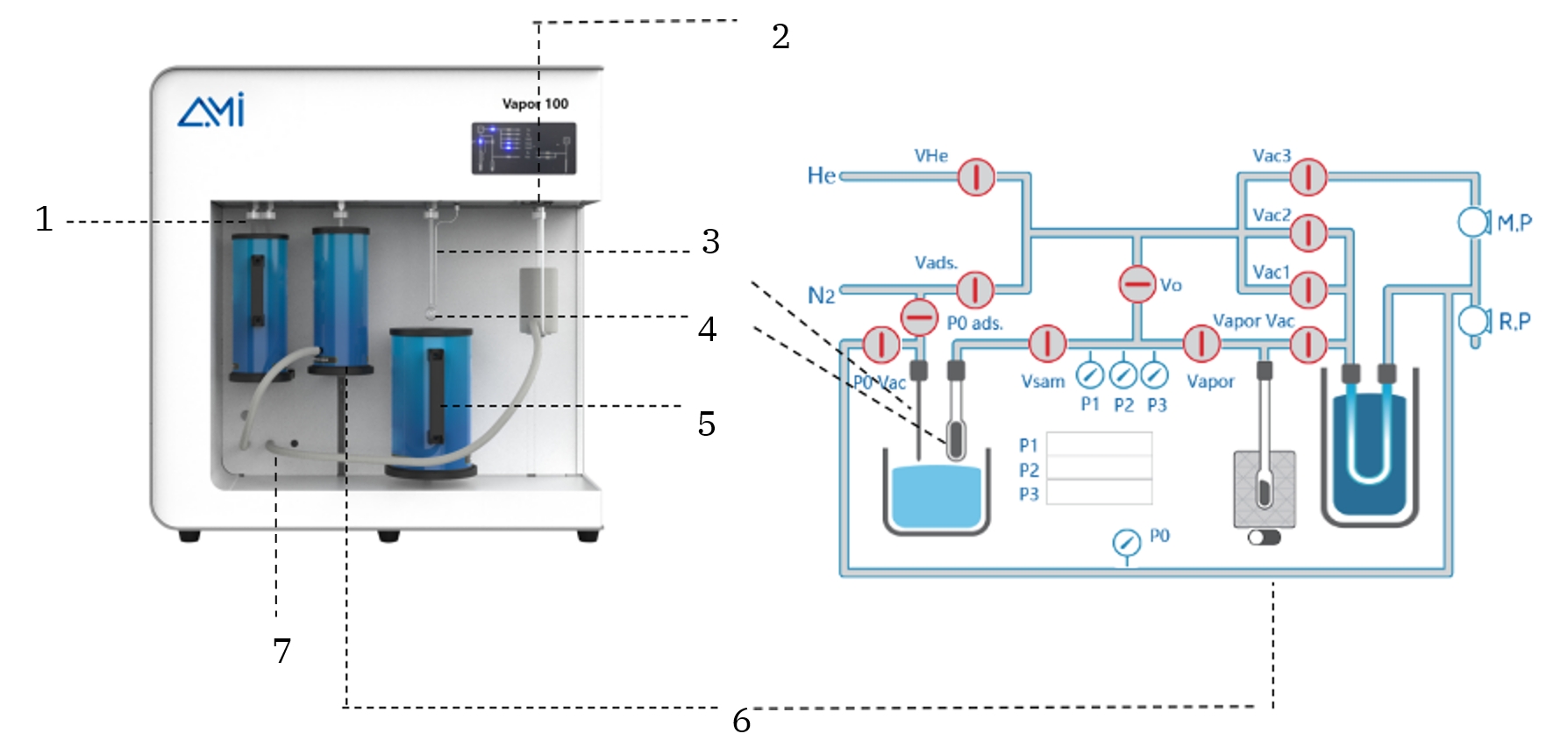

1 Vapor Sorption Port |

1 Vapor Sorption Port; 1 Gas Sorption Port; |

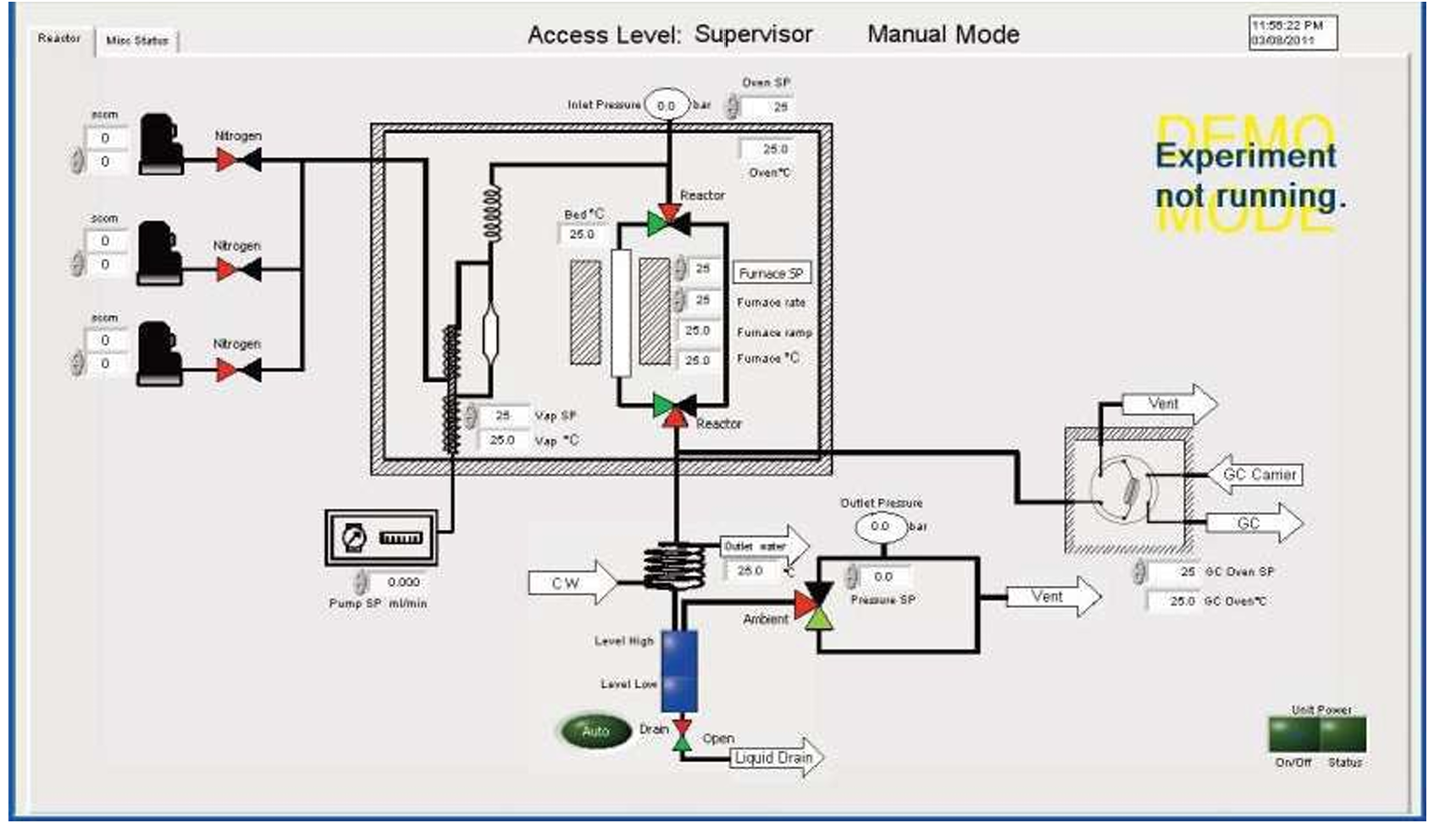

| P0 Transducer |

1 |

| Analysis Pressure Transducer |

3 |

4 |

6 |

| Vapor Sorption Port |

1000 torr, 100 torr, 10 torr |

| Gas Sorption Port |

N/A |

1000 torr |

1000 torr, 10 torr, 1(0.1) torr |

| Pump |

1 mechanical pump (ultimate vacuum 10-2 Pa)

(1 extra mechanical pump for degassing ports is optional) |

1 mechanical pump (ultimate vacuum 10-2 Pa) 1 Turbo molecular pump (ultimate vacuum 10-8 Pa) |

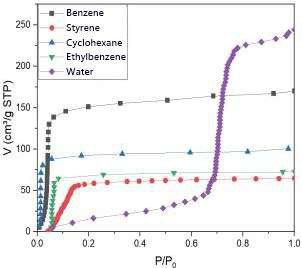

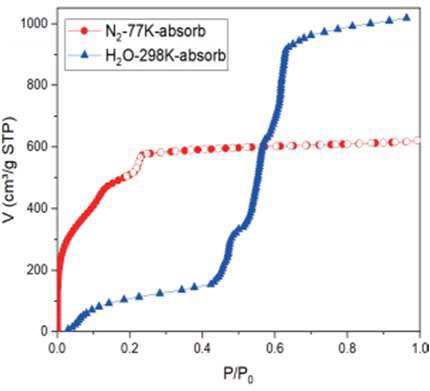

| P/P0 |

10-4 - 0.998 |

10-8 - 0.998 |

| Surface Area |

≥ 0.0005 m2/g, test repeatability: RSD ≤ 1.0% |

| Pore Size |

0.35-500 nm, test repeatability: ≤0.2 nm |

0.35-500 nm, test repeatability: ≤0.02 nm |

| Pore Volume |

≥ 0.0001 cm3/g |

| Degassing Ports |

1 in-situ; 1 ex-situ; |

2 in-situ |

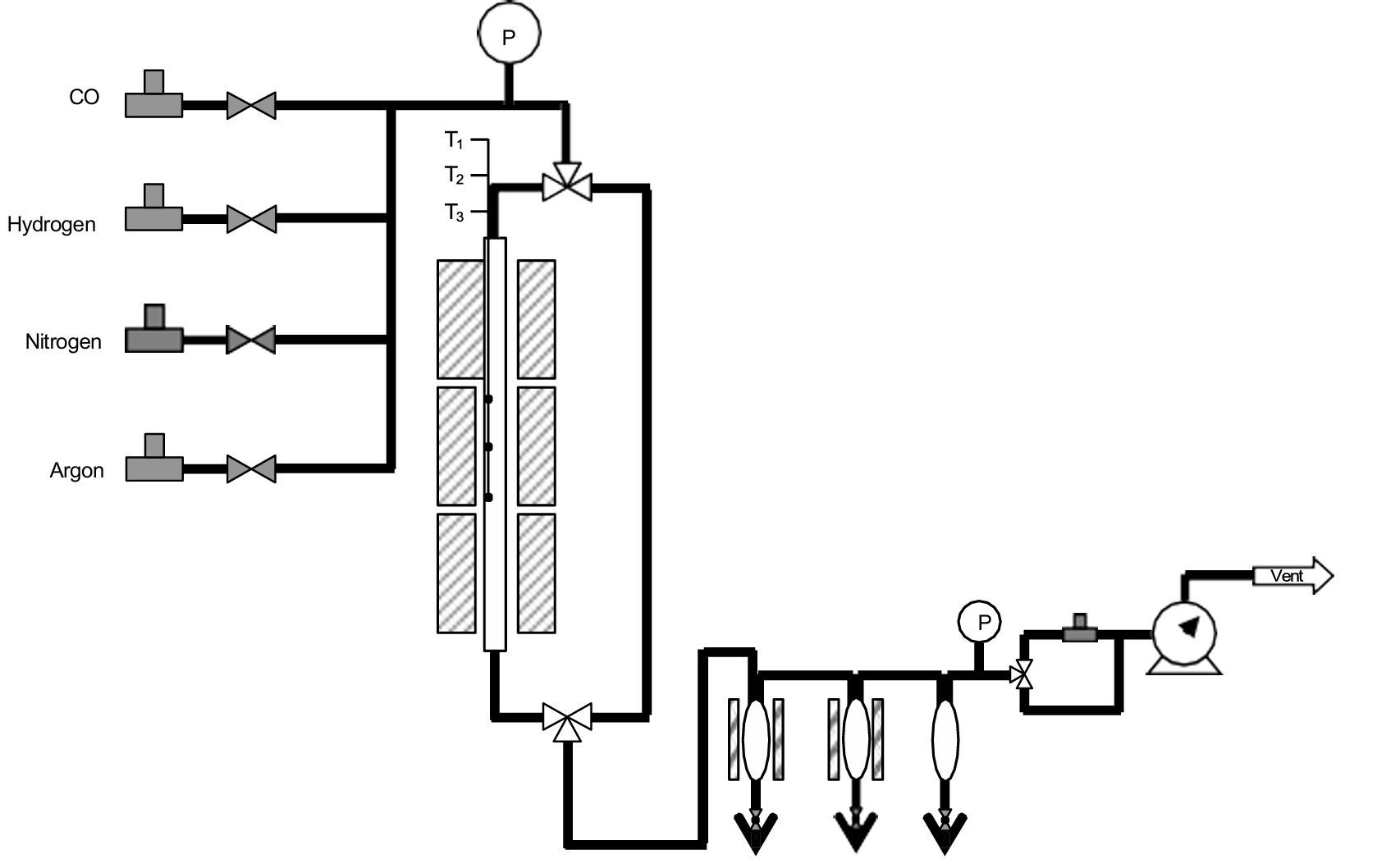

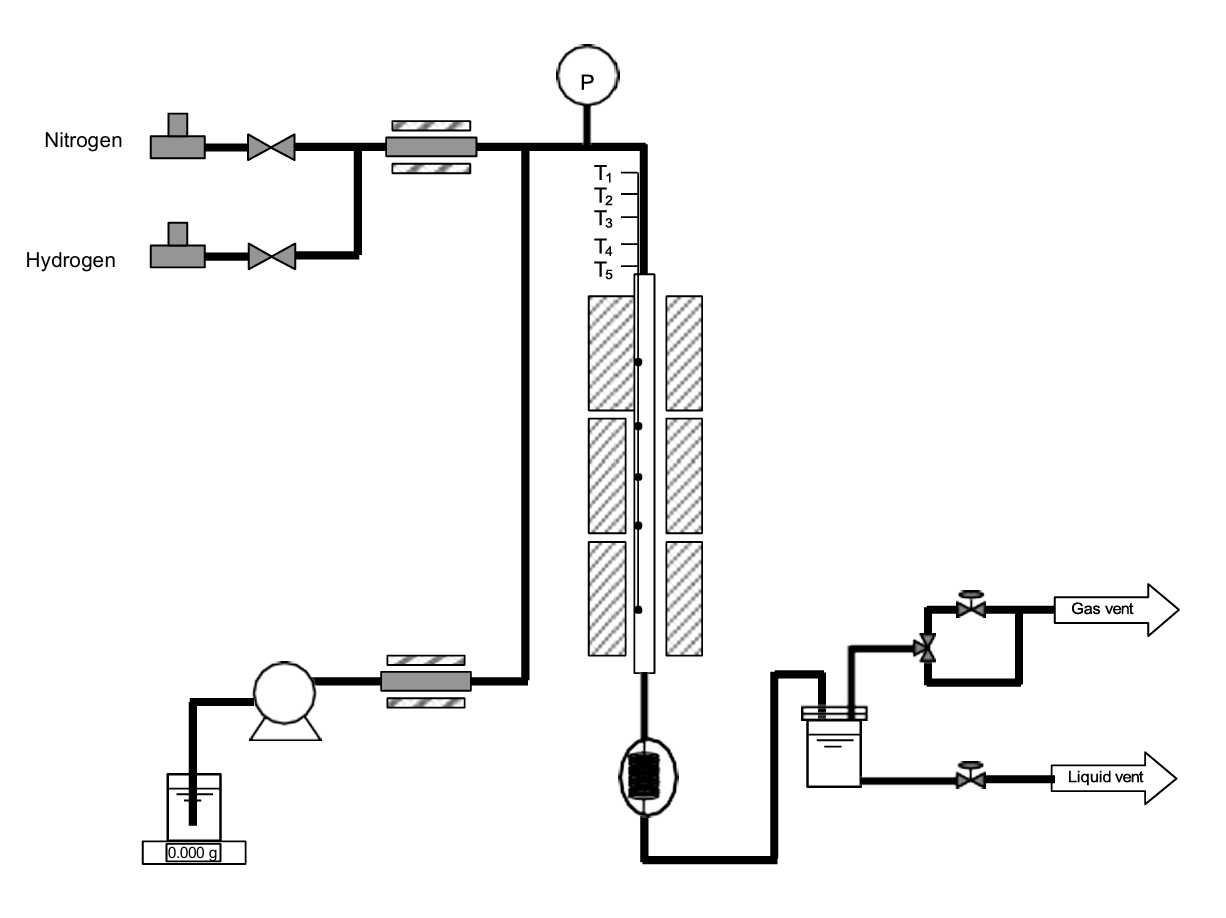

| Adsorbates |

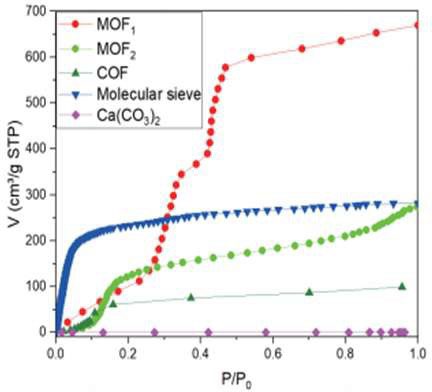

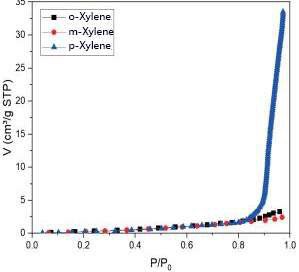

Gas: N2, CO2, Ar, Kr, H2, O2, CO, CH4, etc.

Vapor: H2O, Benzene, Olefins, etc. |

| Cold Trap |

2 |

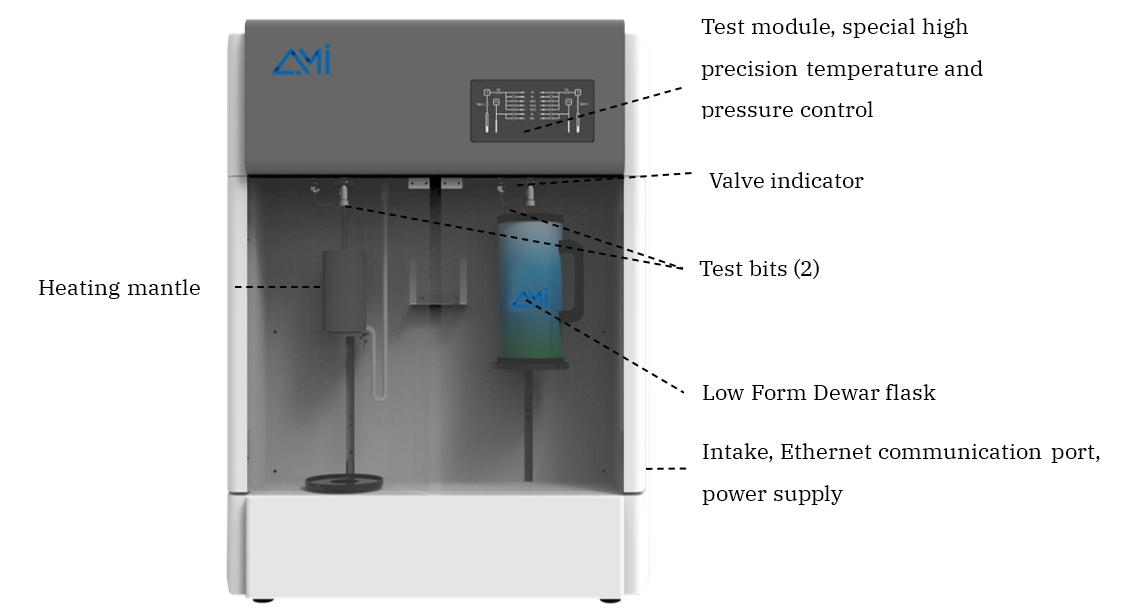

| Volume and Weight |

L 35.5 in (900 mm) × W 22.5 in (570 mm) × H 36.5 in (920 mm), 210 lbs (95 kg) |

| Power Requirements |

110V or 200-240 VAC, 50/60 Hz, maximum power 300 W |

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com