Meso 400

INTRODUCTION

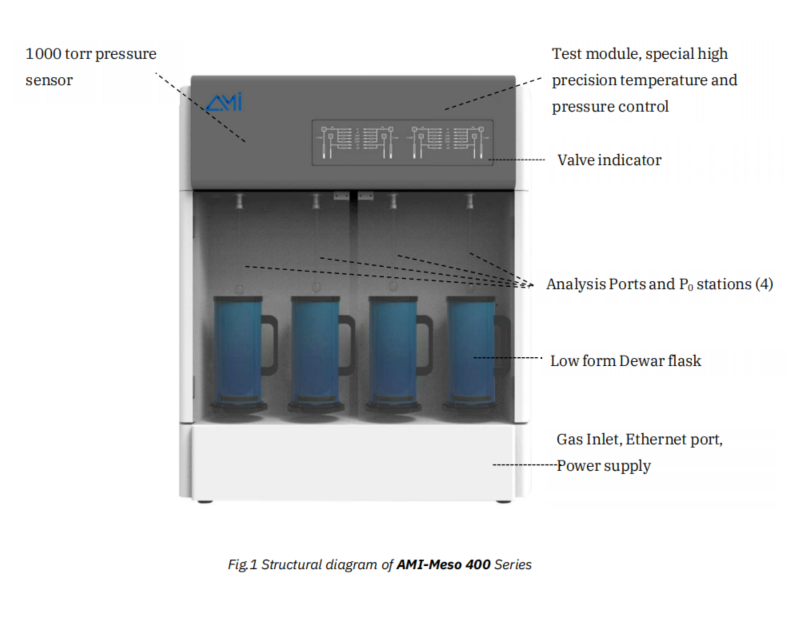

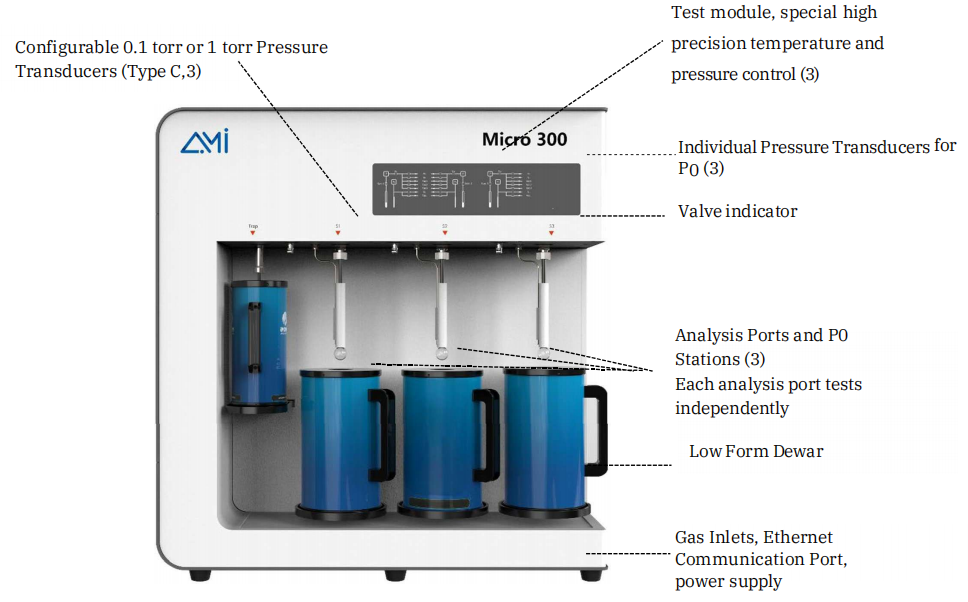

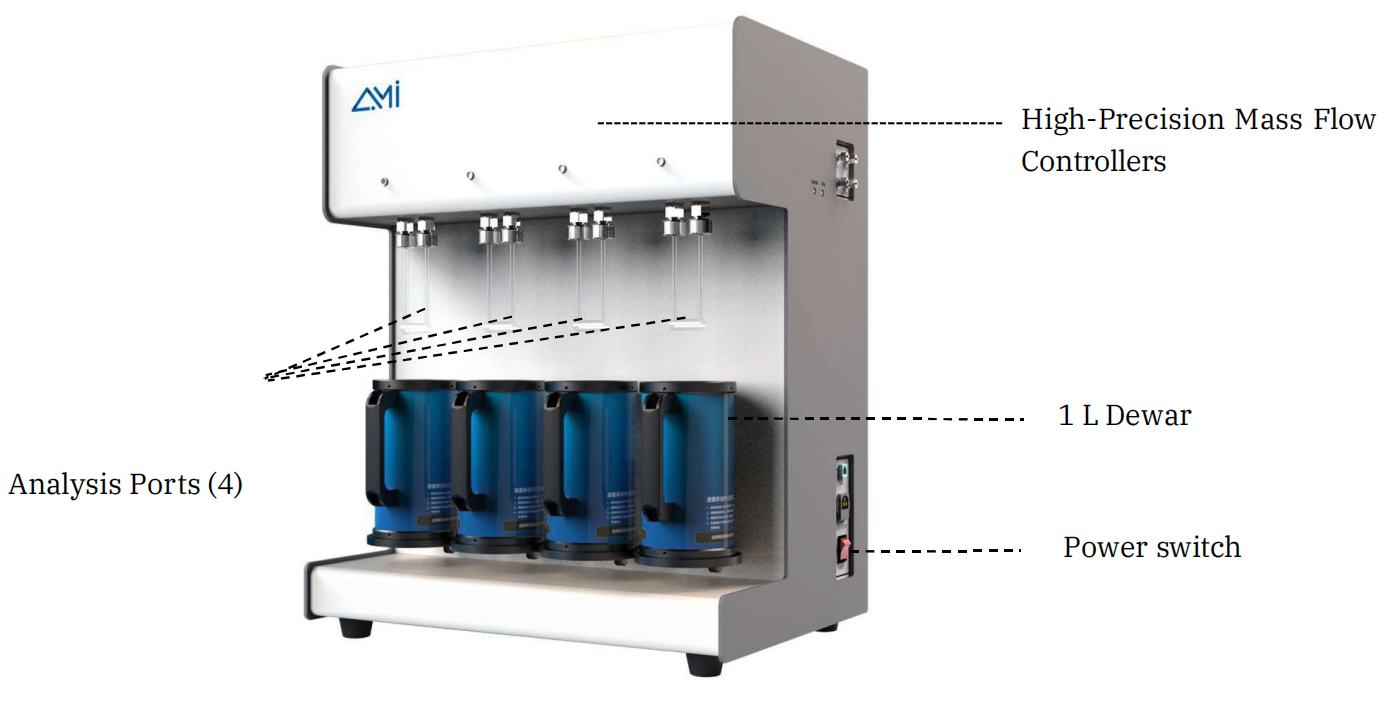

- The AMI-Meso 400 is a compact, high-performance sorption analyzer designed for the precise characterization of mesoporous and macroporous materials. Equipped with four fully independent analysis stations, it enables the determination of BET surface area, total pore volume, and pore size distribution with maximum efficiency.

- Each analysis station features an individual dosing volume, allowing fully autonomous operation with independent programming and initiation at any time—eliminating downtime between analyses. This design ensures highly reproducible results and optimized throughput.

- The AMI-Meso 400 supports a wide range of non-corrosive adsorptive gases, including N2, CO2, Ar, Kr, H2, O2, CO, NH₃, and CH4, providing exceptional flexibility for various research and industrial applications. Additionally, all four stations function as in-situ degassing units, enabling efficient sample preparation within the same system.

KEY FEATURES

- Module Design for Minimal Dead Volume

- The internal gas path design of the instrument adopts a unique integrated metal module design, which not only reduces the internal dead volume spacebut also helps mitigate possible leaks.

- Saturated Vapor Pressure P0

- An independent P0 pressure transducer is configured at 133 kPa for P0 value testing,enabling real-time P/P0 measurement for more accurate and reliable test data. Alternatively, an atmospheric pressure input method can be used to determine P0.

- Independent analysis ports

- With independent analysis ports, the system employs a unique vacuum control logic that allows each station to operate without disruption, even when using a single mechanical pump or pump group. This enables simultaneous, independent experiments, meeting diverse adsorbent testing needs while ensuring high efficiency.

- Thermal Stabilization

- A core rod in the sample tube reduces deadvolume and stabilizes the cold free space coefficient, while an iso-thermal jacket maintains a constant thermal profile along the tube. Additionally, automatic helium correction ensures precise calibration for any powder or particulate material, minimizing temperature-related deviations during analysis.

- High Accuracy Pressure Transducers

- Equipped with 1000 torr pressure transducers, the Meso Series enables precise physical adsorption analysis, achieving a partial pressure (P/P0) as low as 10-2 for nitrogen (N2) at 77 K.

- Optimized Manifold Contamination Control

- This system features a multi-channel, adjustable, and parallel vacuum design with segmented vacuum control. This setup effectively prevents samples from being drawn up into the analyzer therefore preventing manifold contamination.

- Liquid Nitrogen Dewar

- The use of 1 L Dewar flasks in conjunction with a sealed cover ensures a stable thermal profile along the entire length of both the sample tubes and P0 tubes throughout the testing process.

- Sample Preparation

- Equipped with four in-situ degassing ports, enabling simultaneous degassing and analysis. Each port offers independent temperature control from ambient to 400°C, ensuring precise sample preparation.

SOFTWARE

- PAS Software is an intelligent solution for operation control, data acquisition, calculation, analysis, and report generation on the Windows platform. It communicates with the host via the LAN port and can remotely control multiple instruments simultaneously.

- PAS Software adopts a unique intake control method, optimizing pressure in the adsorption and desorption processes through a six-stage setting, which improves testing efficiency.

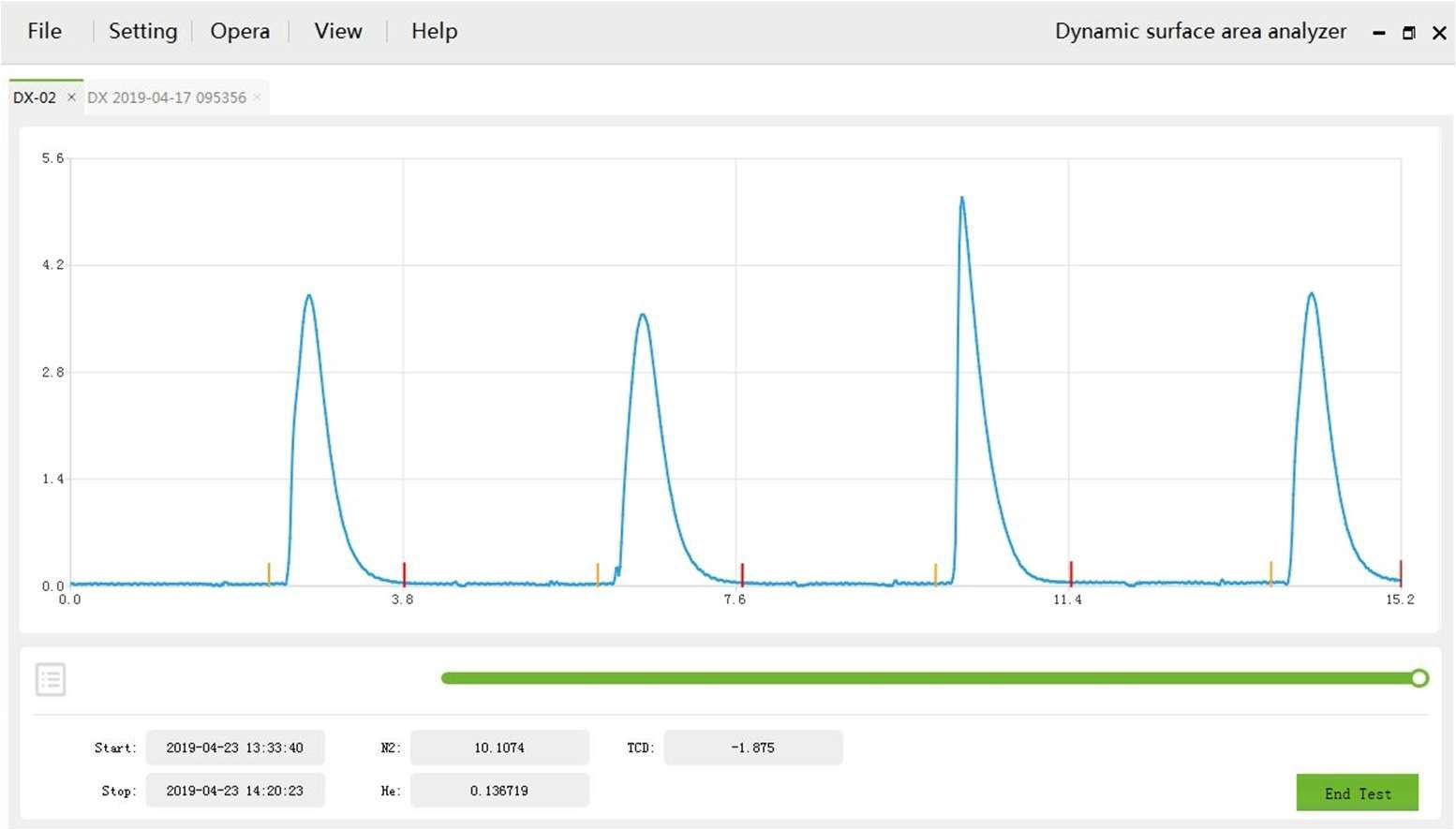

- Changes in pressure and temperature inside the manifold can be directly observed in the test interface, providing convenience for sample testing and instrument maintenance. The current state of analyzer can be intuitively understood with the indicator light and event bar.

- Each adsorption equilibrium process is dynamically displayed on the test interface. Adsorption characteristics of the sample can be easily understood.

- A clear and concise report setting interface, including the following:

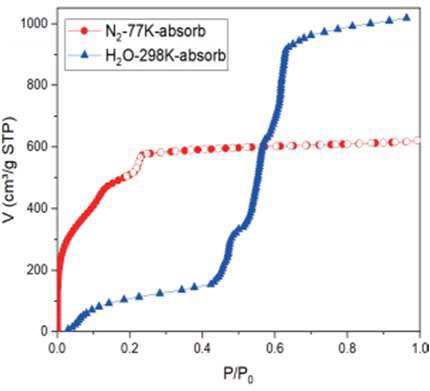

- Adsorption and desorption isotherms

- Single-/Multipoint BET surface area

- Langmuir surface area

- STSA-surface area

- Pore size distribution according to BJH

- T-plot

- Dubinin-Radushkevich

- Horvath-Kawazoe

- Saito-Foley

TYPICAL ANALYSIS RESULTS

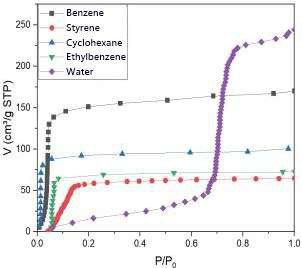

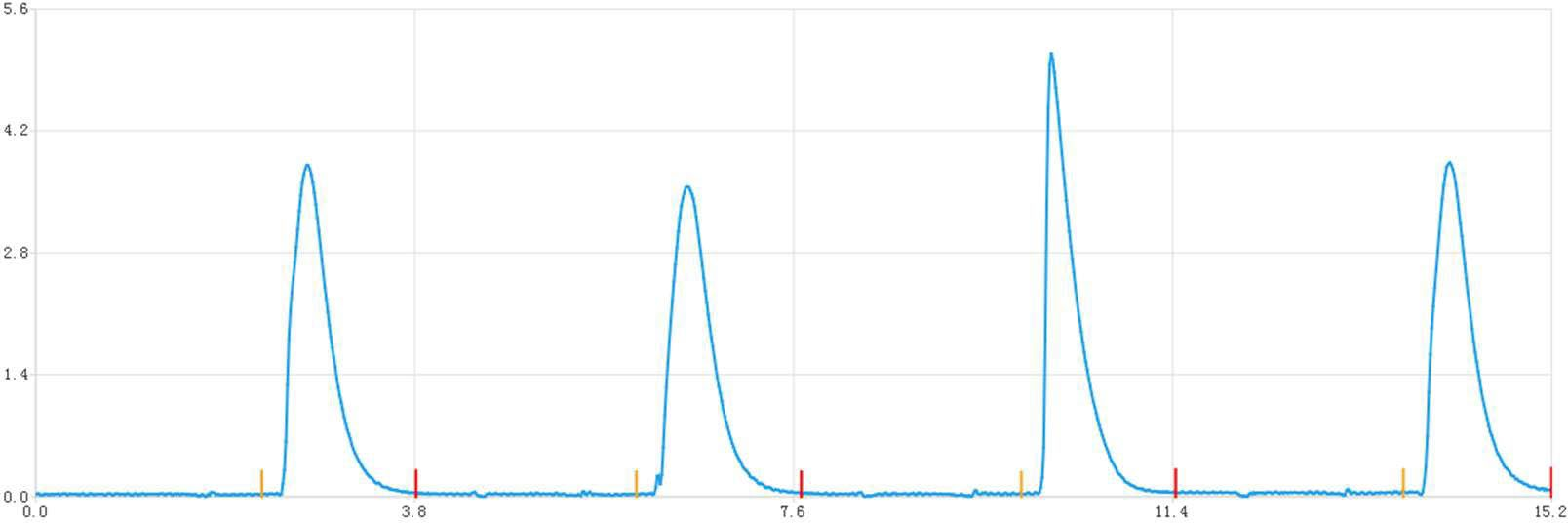

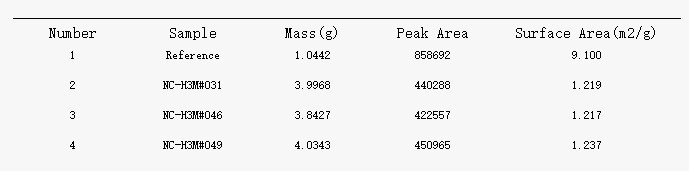

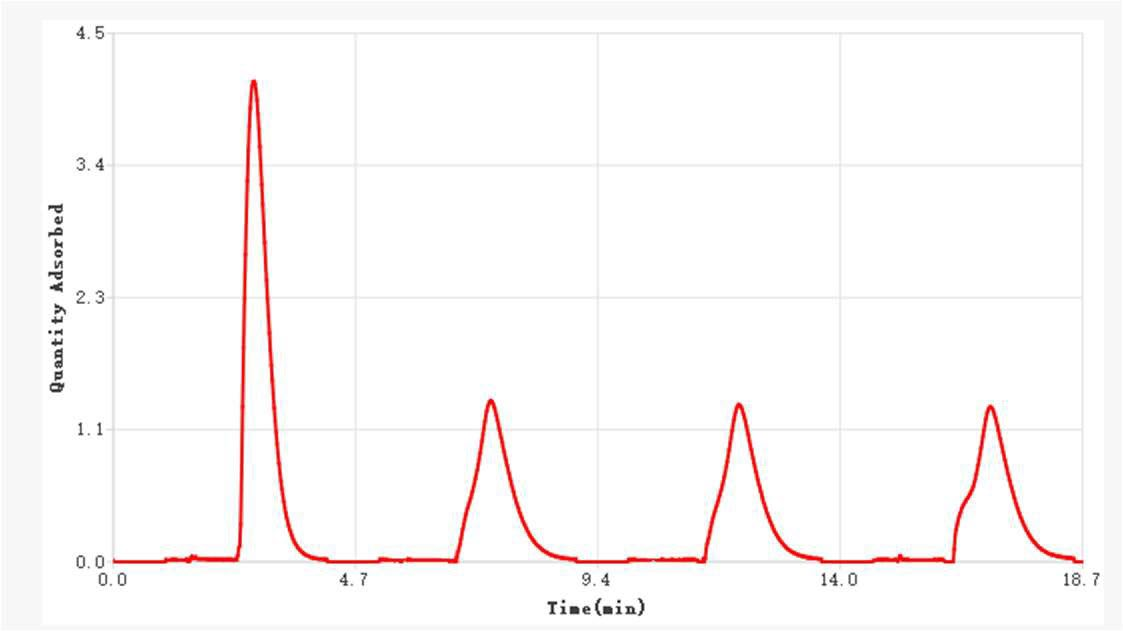

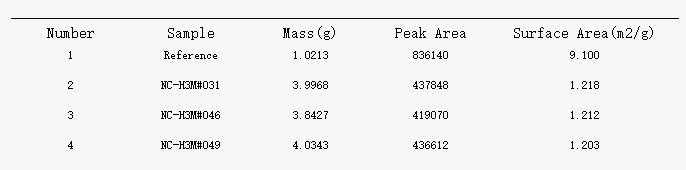

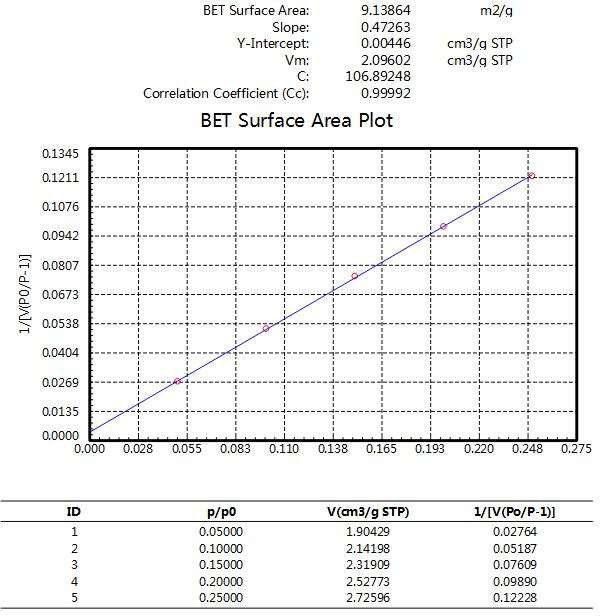

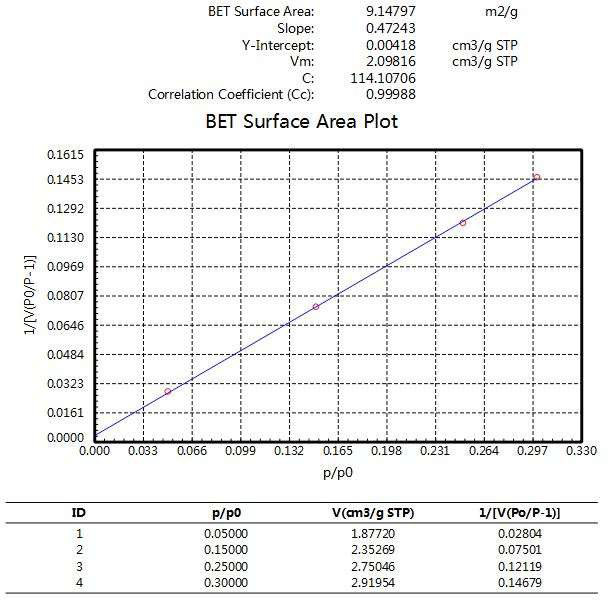

- The specific surface area test results for iron ore powder are shown in the figure below. As a material with an inherently low specific surface area, the repeatability error in the measurements is only 0.0015 m²/g, demonstrating high testing precision.

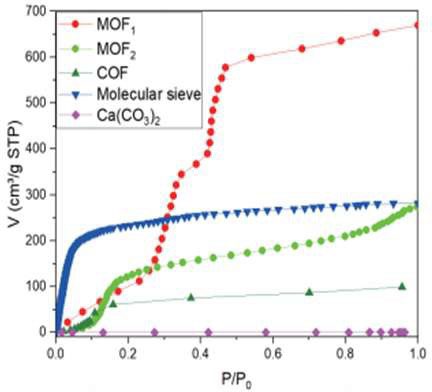

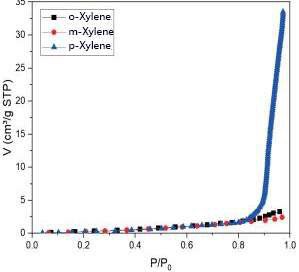

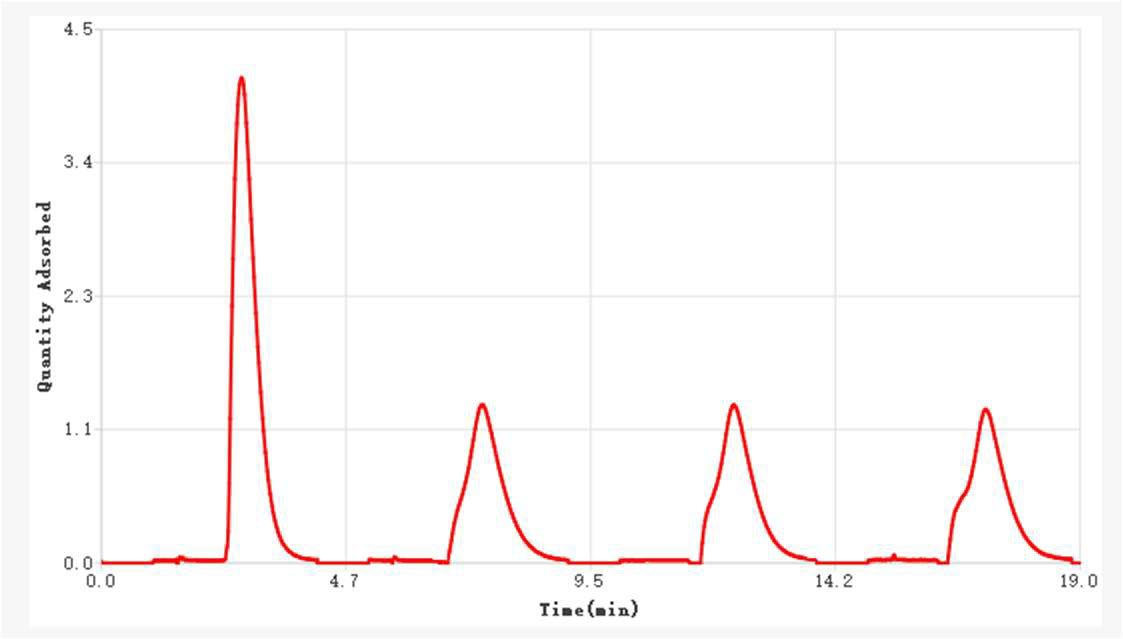

- Analysis of pore size distribution of activated carbon materials by NLDFT.

- Adsorption and Desorption Isotherms of typical macroporous material - silica.

APPLICATIONS

| Applied Field | Typical Materials | Details |

|---|---|---|

| Material Research | Ceramic powder, metal powder, nanotubes | According to the surface area value of the nanotube, hydrogen storage capacity can be predicted. |

| Chemical Engineering | Carbon black, amorphous silica, zinc oxide, titanium dioxide | Introduction of carbon black in rubber matrix can improve mechanical properties of rubber products. Surface area of carbon black is one of the important factors affecting the reinforcement performance of rubber products. |

| New Energy | Lithium cobalt, lithium manganate | Increasing the surface area of the electrode can improve the Electrochemical reaction rate and promote iron exchange in the negative electrode. |

| Catalytic Technologies | Active alumina oxide, molecular sieve, zeolite | Active surface area and pore structure influence reaction rate. |

SPECIFICATIONS

| Model | AMI Meso 400 | ||

| Analysis Ports | 4 | ||

| P0 Transducer | 4 | ||

| Analysis Pressure Transducer | 4 | ||

| Accuracy Pressure Transducers | 1000 torr | ||

| Pump | 1 mechanical pumps(ultimate vacuum10-2 Pa) | ||

| P/P0 | 10-4-0.998 | ||

| Surface Area | ≥0.0005 m2/g,test repeatability:RSD≤1.0% | ||

| Pore Size |

0.35-500 nm,test repeatability:≤0.02 nm |

||

| Pore Volume | ≥0.0001 cm3/g | ||

| Degassing Ports | 4 in-situ | ||

| Adsorbates | N2, Ar, Kr, H2, O2, CO2, CO, NH3, CH4, etc.. | ||

| Cold Trap | 1 | ||

| Volume and Weight | 38.5 in (980 mm) × W 25.0 in (630 mm) × H 38.5 in (976 mm), 176-199 lbs (90 kg) | ||

| Power Requirements | 110 or 200-240VAC, 50/60Hz, maximum power300 W | ||

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com