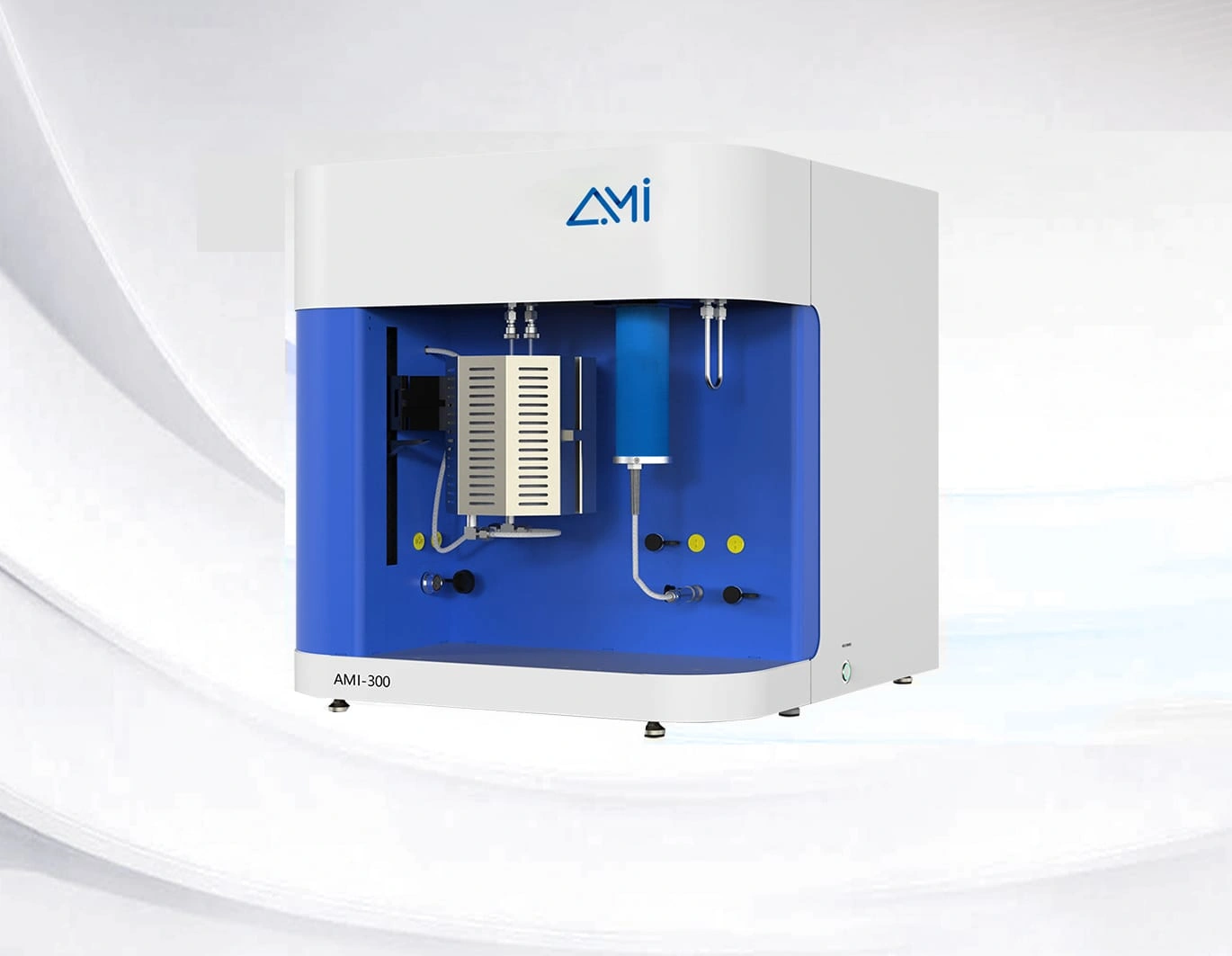

Proprietary Microbalance

The proprietary TGA microbalance combines high sensitivity, low drift technology, and thermal insulation design to deliver exceptional weighing accuracy. With a resolution as precise as 0.1 μg, it is ideal for high-precision measurements of trace samples. The low-drift technology minimizes the impact of environmental factors, ensuring stable data even in long-duration experiments, while reducing errors caused by drift. Additionally, the thermal insulation design protects the balance from external temperature fluctuations, maintaining internal temperature stability and ensuring reliable results, even in conditions of rapid temperature change or high heat.

Miniature Furnace

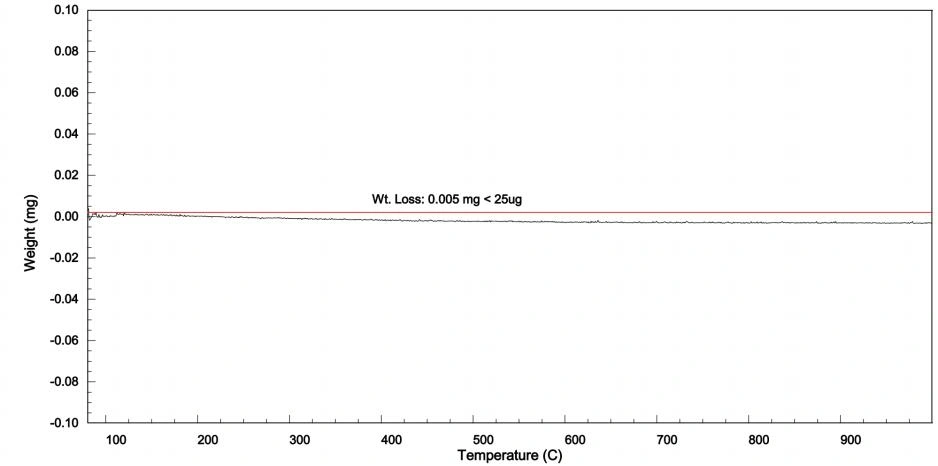

The compact heating furnace is designed to significantly minimize gas buoyancy effects, ensuring that dynamic curve drift in TGA remains under 25 μg without requiring additional blank tests. Additionally, the furnace delivers a rapid temperature response, achieving heating rates of up to 300°C/min, which dramatically shortens experimental time and enhances overall work efficiency.

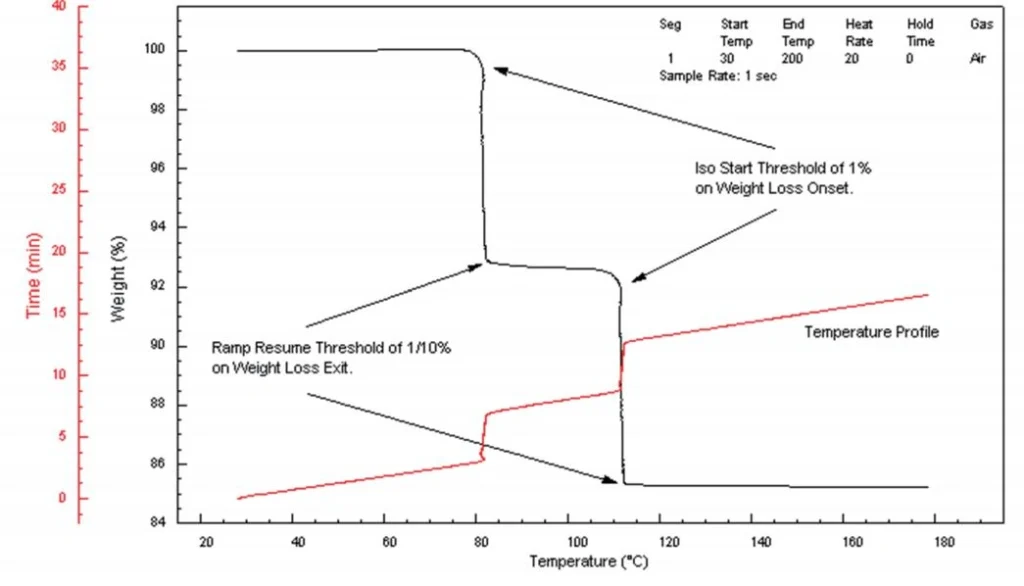

Precise Temperature Control

The advanced heating technology combined with a dual PID control system ensures precise adherence to the set temperature curve during both heating and cooling processes. With a temperature control accuracy of ±0.1°C, this system significantly reduces the influence of temperature fluctuations, delivering highly reliable experimental results.

Multiple furnace options are available to meet the specific temperature

requirements of different materials. With a maximum temperature

capability of up to 1500°C, these furnaces are designed to satisfy the

rigorous demands of both experimental and industrial applications.

Wide Temperature Range

Multiple furnace options are available to meet the specific temperature requirements of different materials. With a maximum temperature capability of up to 1500°C, these furnaces are designed to satisfy the rigorous demands of both experimental and industrial applications.

Furnace Auto-Lift System

The instrument is equipped with an automatic furnace lifting system, simplifying experimental operations and preventing equipment damage or safety incidents caused by improper manual handling.