TPO coke analysis helps quantify coke deposits on coked catalysts by tracking CO₂ during temperature-programmed oxidation […]

TPO coke analysis helps quantify coke deposits on coked catalysts by tracking CO₂ during temperature-programmed oxidation. When paired with CO₂-to-CH₄ methanation and FID detection, it enables highly sensitive, real-time monitoring of coke oxidation rate and coke type distribution.

Heterogeneous catalysis is integral to a wide array of industrial applications, including energy, chemical synthesis, and consumer products. Traditionally, a solid or powder catalyst is employed to transform gas phase hydrocarbons into valuable products. Elemental carbon deposition onto the catalyst, or “coking,” is an undesirable side reaction that, over time, will block the catalytic sites and deactivate the catalyst. Therefore, characterization of carbon deposits is essential for improving catalyst performance. Today, advanced techniques such as transmission electron microscopy (TEM), laser Raman spectroscopy, electron energy loss spectroscopy (EELS), solid-state ¹³C NMR, and temperature-programmed oxidation (TPO) are widely used to study coked catalysts. Among these, TPO has become one of the most commonly applied methods due to its simplicity and effectiveness.¹

Temperature-programmed oxidation (TPO) is a materials characterization technique in which the sample is exposed to oxidizing gas, and the oxidizer chemically binds (chemisorbs) onto the surface. As the material temperature is increased, the oxidized surface species desorb from the material and are analyzed by a detector. For coke analysis, the catalyst is heated under O₂ flow, and surface carbon is oxidized to CO₂. The amount of desorbed CO₂ is directly related to the amount of coke, and the temperature at which CO₂ desorbed can differentiate between types of carbon on the catalyst. Typically, the desorbed product is analyzed by a thermal conductivity detector (TCD) or flame ionization detector (FID), but neither detector is sufficiently sensitive to CO₂. Therefore, a methanation step can be employed to convert CO₂ into CH₄, which is easily measured by a flame ionization detector (FID). This process is shown in Scheme 1.

This AMI Note discusses the use of TPO combined with an innovative detection method developed by Dr. S.C. Fung and Dr. C.A. Querini at Exxon Research and Engineering Company.² This approach is straightforward and enables continuous monitoring of the rate of coke oxidation.

Scheme 1. Step-by-step process for detection of coke through sequential temperature-programmed oxidation (TPO) and methanation using an AMI catalyst characterization system equipped with a methanator and FID.

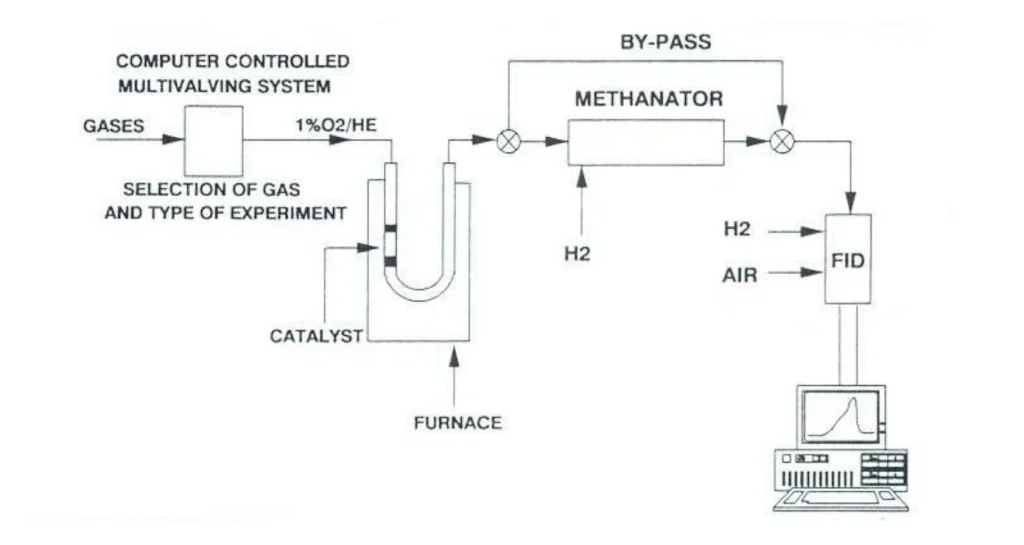

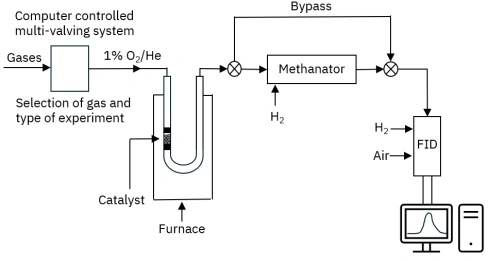

Figure 1: System flow diagram for AMI catalyst characterization system equipped with temperature-programmed oxidation (TPO) flow reactor, methanator, and FID

AMI is currently the only company to offer customizable catalyst characterization systems capable of such advanced TPO techniques.

TPO coke analysis helps quantify coke deposits on coked catalysts by tracking CO₂ during temperature-programmed oxidation […]

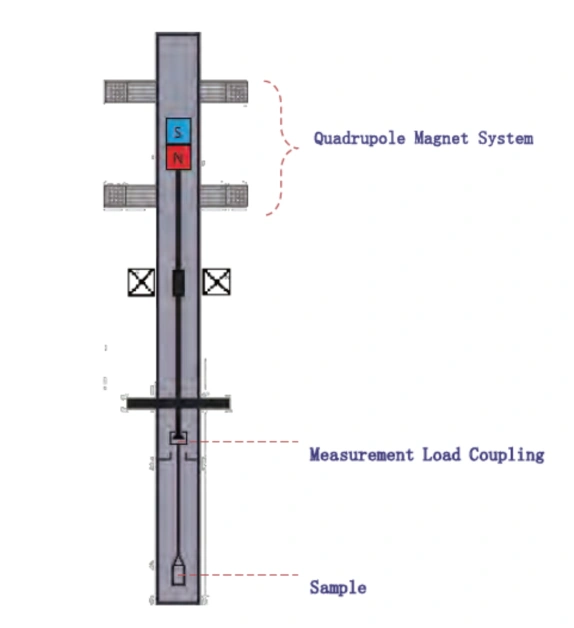

Magnetic Suspension Balances (MSBs) have become indispensable tools for gravimetric analysis under extreme conditions—including high pressures, elevated temperatures, and corrosive atmospheres […]

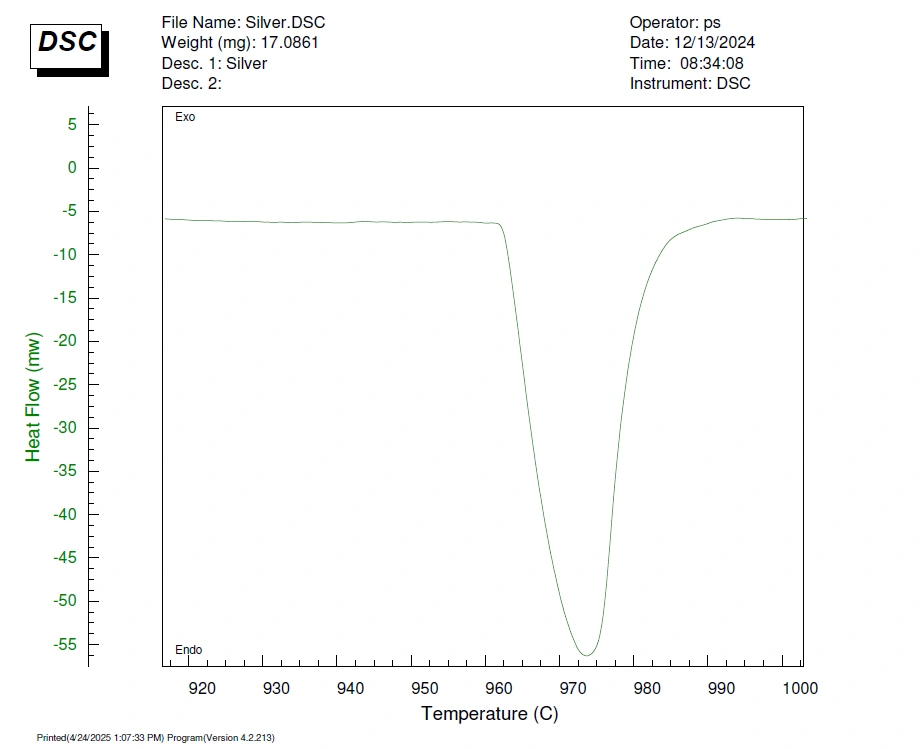

Differential Scanning Calorimetry (DSC) is a fundamental technique used to study phase transitions, heat capacity, and thermal stability in materials […]

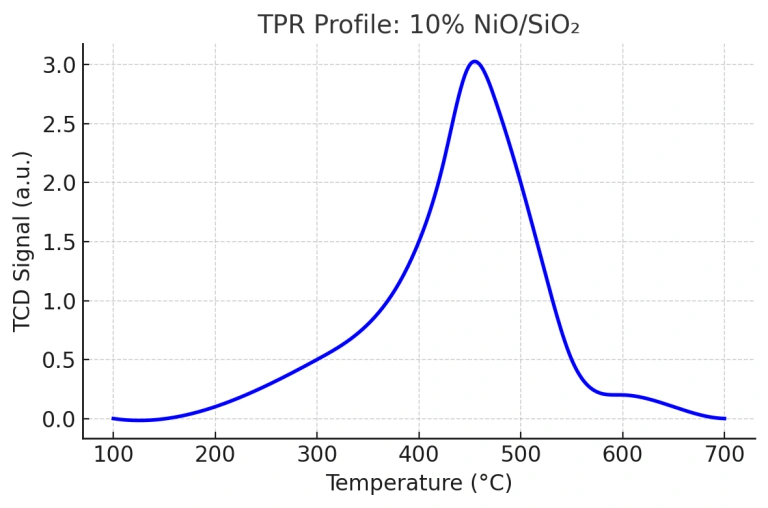

Temperature-programmed reduction (TPR) is a powerful technique for obtaining direct information on the reducibility of catalysts and catalyst precursors […]