Magnetic suspension balance. Gravimetric sorption in real-world conditions. Dual-sample testing, up to 400°C.

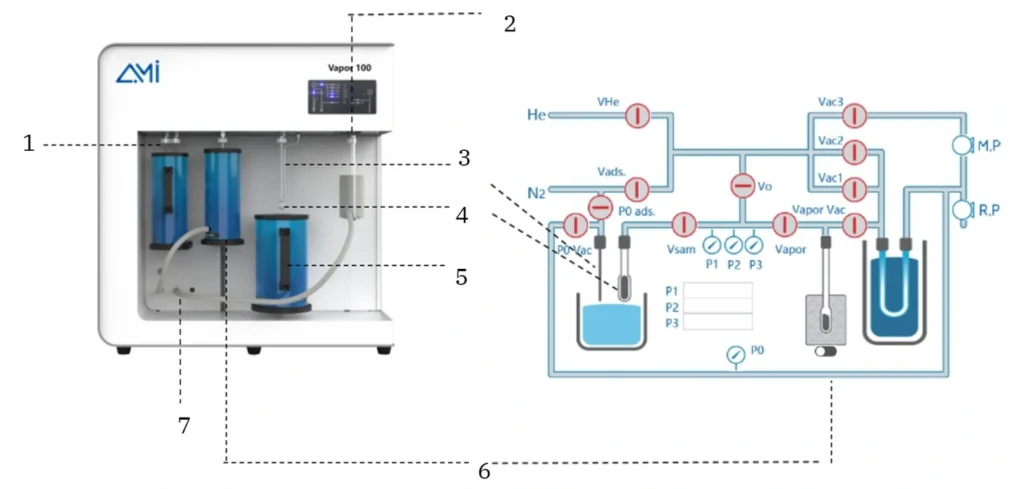

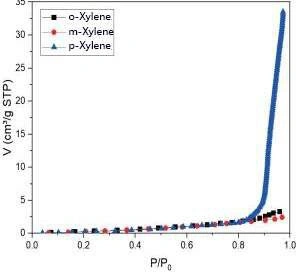

The AMI Vapor Series instruments are precision volumetric analyzers designed for advanced vapor and gas sorption characterization. These systems are ideal for analyzing adsorption isotherms, surface area, pore size distributions, and gas selectivity, using noncorrosive and safe adsorbates under controlled conditions.

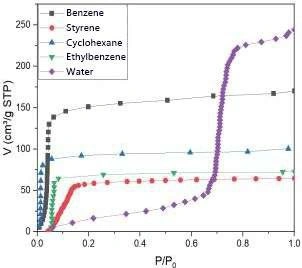

Typical adsorbates include water vapor, benzene, carbon monoxide, ammonia, and other non-corrosive gases and vapors at room temperature.