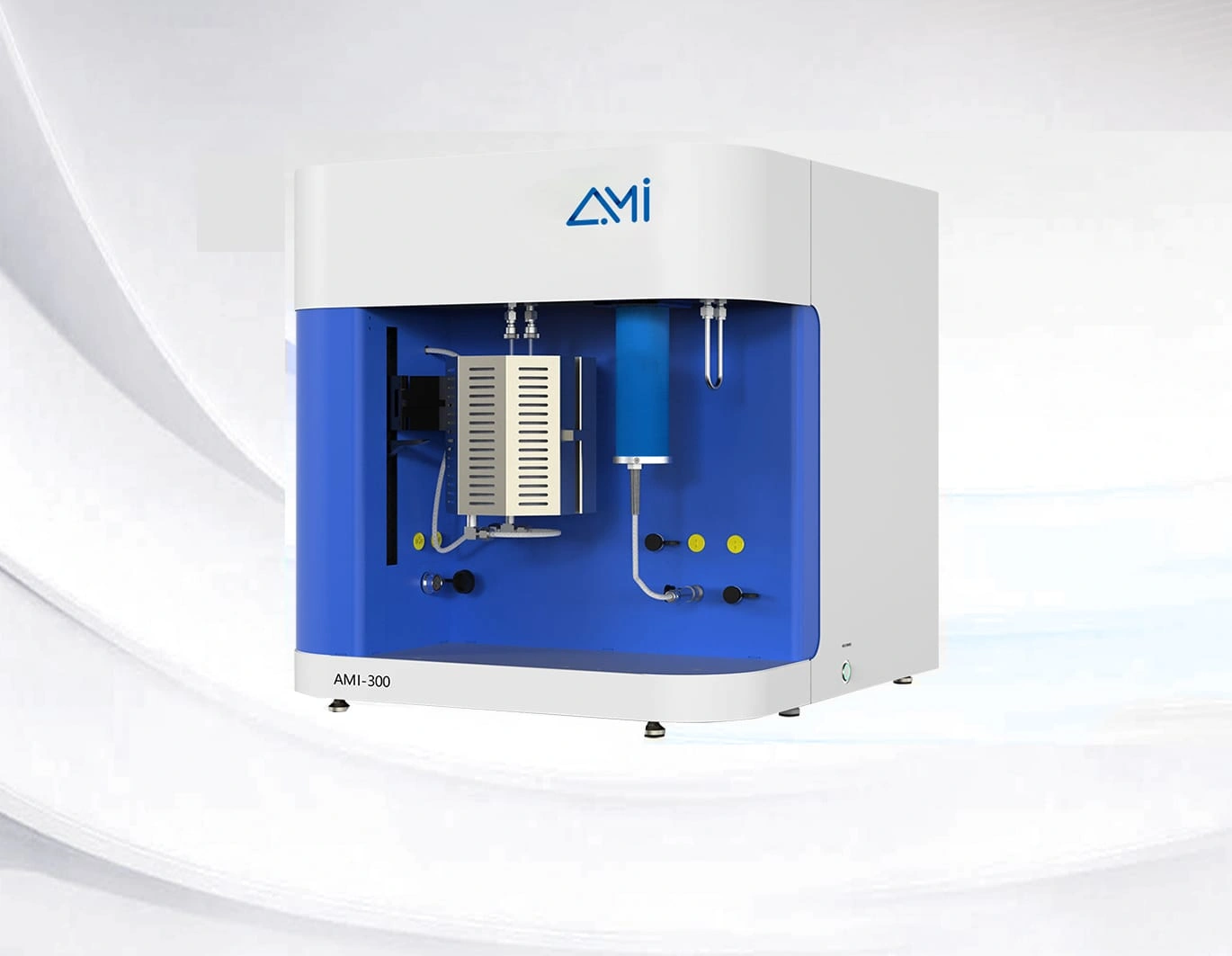

Magnetic suspension balance. Gravimetric sorption in real-world conditions. Dual-sample testing, up to 400°C.

Integrated Exhaust Fan – Prevents the accumulation of toxic and harmful gases, ensuring a safe and controlled operating environment.

Comprehensive Temperature Monitoring – Continuously tracks internal instrumentation temperature, TCD temperature, and process component temperatures to ensure precise thermal control and operational safety.

Intelligent Fault Diagnosis & Alarm System – Features automated fault detection and real- time alerts, enhancing system reliability, protection, and user safety.

Self-Locking Door

The instrument features an interlocked safety door, designed to prevent accidental contact during experiments. Equipped with an electronic safety lock, it ensures the door remains securely closed throughout the process, providing enhanced safety and operational reliability.

Triple Thermocouple Design

The system incorporates a Triple Thermocouple Design for precise temperature control and enhanced safety:

• Bed Temperature Control Thermocouple – Ensures accurate temperature regulation of the sample.

• Furnace Thermocouple – Monitors and stabilizes the overall furnace environment.

• Overtemperature Protection Thermocouple – Provides an additional safety layer to prevent overheating.

Hard Wired Over-Temperature

power protection system, ensuring safe and reliable operation.