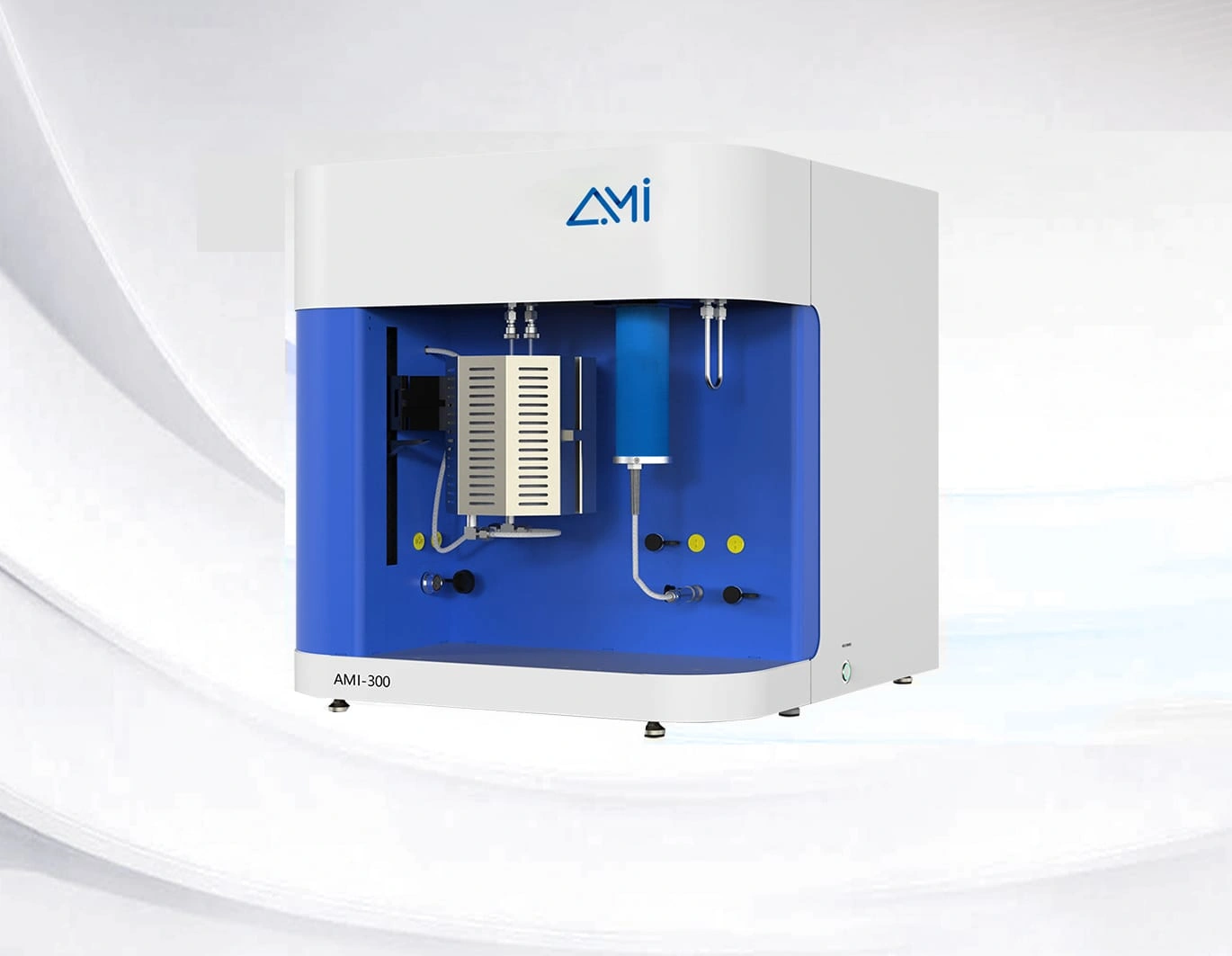

Magnetic suspension balance. Gravimetric sorption in real-world conditions. Dual-sample testing, up to 400°C.

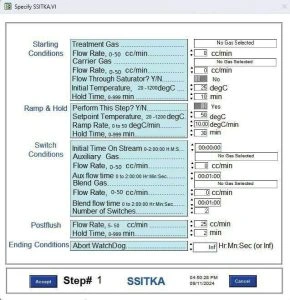

Precision flow control system

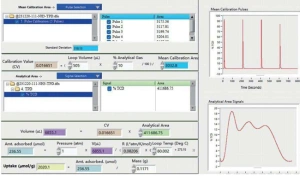

High-precision MFCs with flow rates from 2-100 sccm.

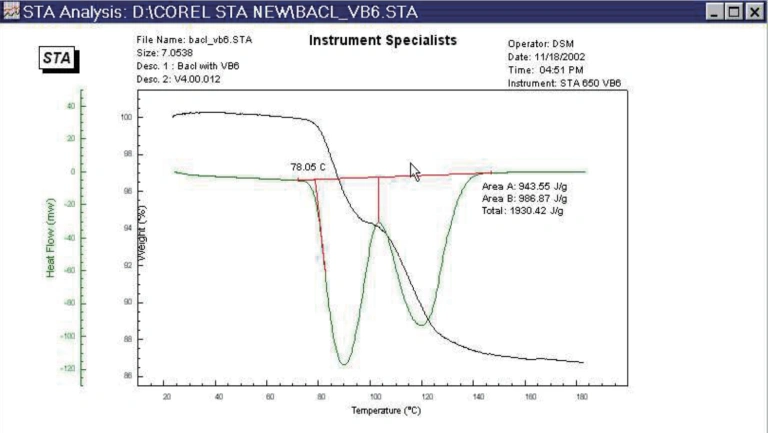

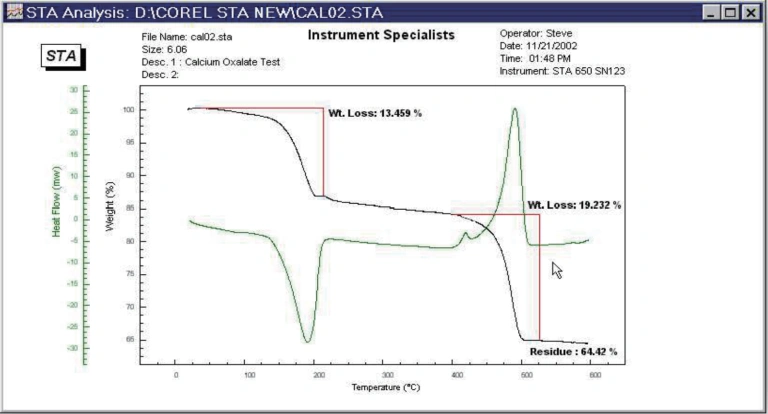

High-Stability Programmed Temperature Reaction System

Engineered with precision temperature control up to 1200°C, this system achieves linear heating rates from 0.1 to 50°C/min with ±0.1°C regulation accuracy.

Rapid Cooling

Featuring automated control, the system enables rapid furnace cooling via air purging to reduce experimental duration.

Minimal Dead Volume

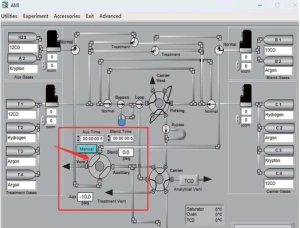

As an instrument capable of performing SSITKA experiments, the AMI-300 SSITKA utilizes 1/16 tubing with an optimized compact design, effectively minimizing dead volume.

Pressure Equalization and valve switching

SSITKA experiments require precise pressure equalization between two streams and rapid valve switching to minimize pressure spike variations in the mass spectrometer signal, ensuring accurate measurements.