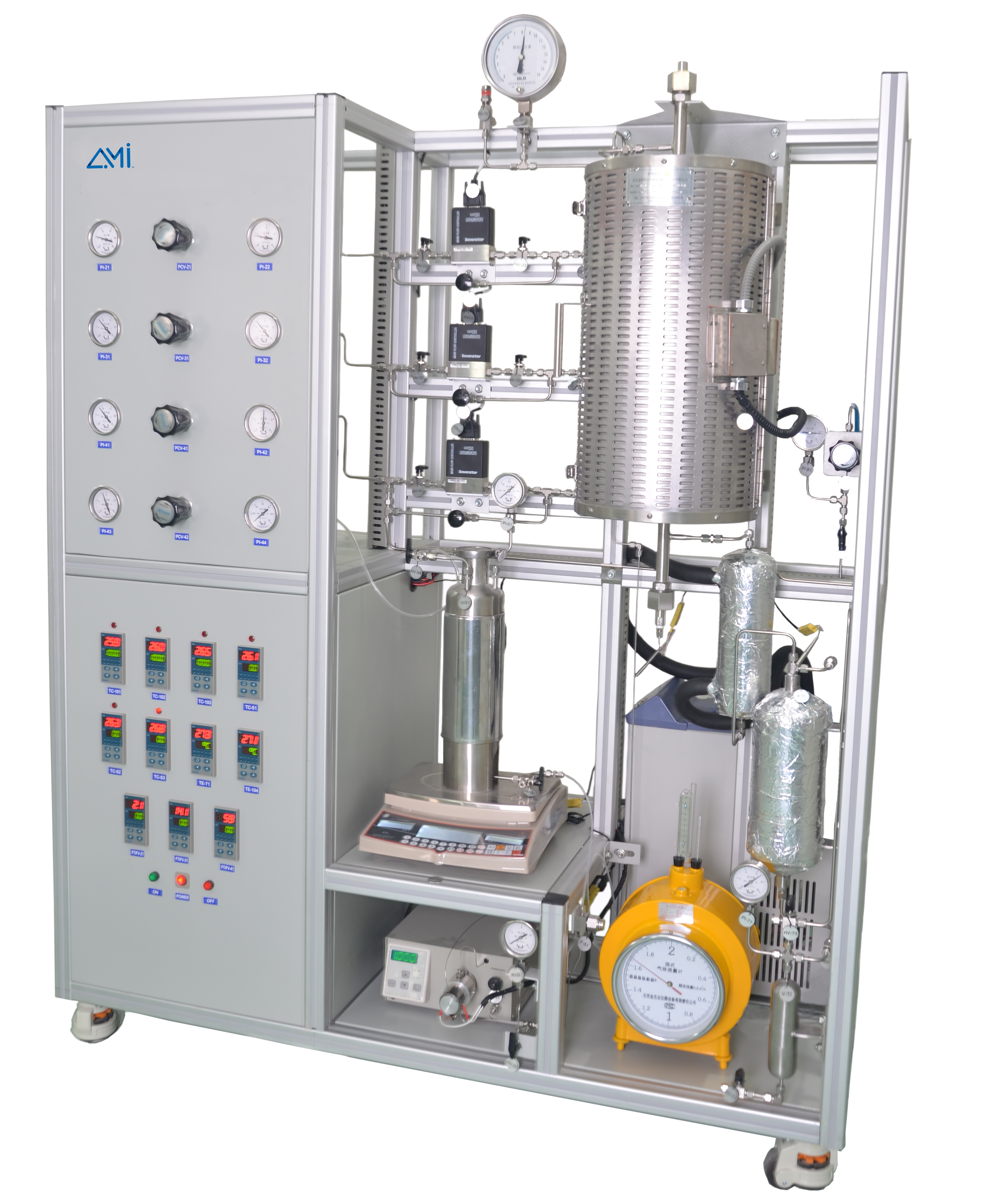

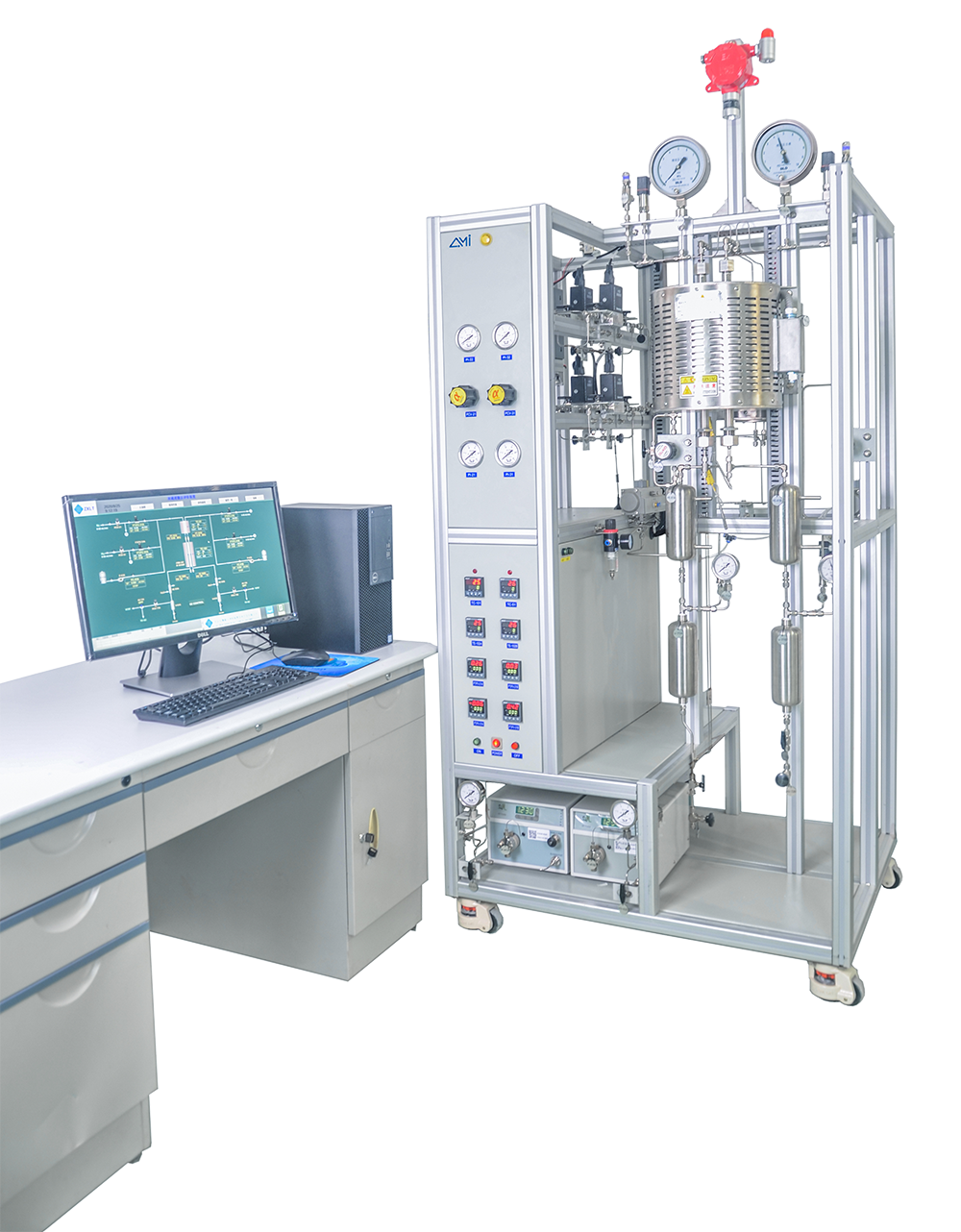

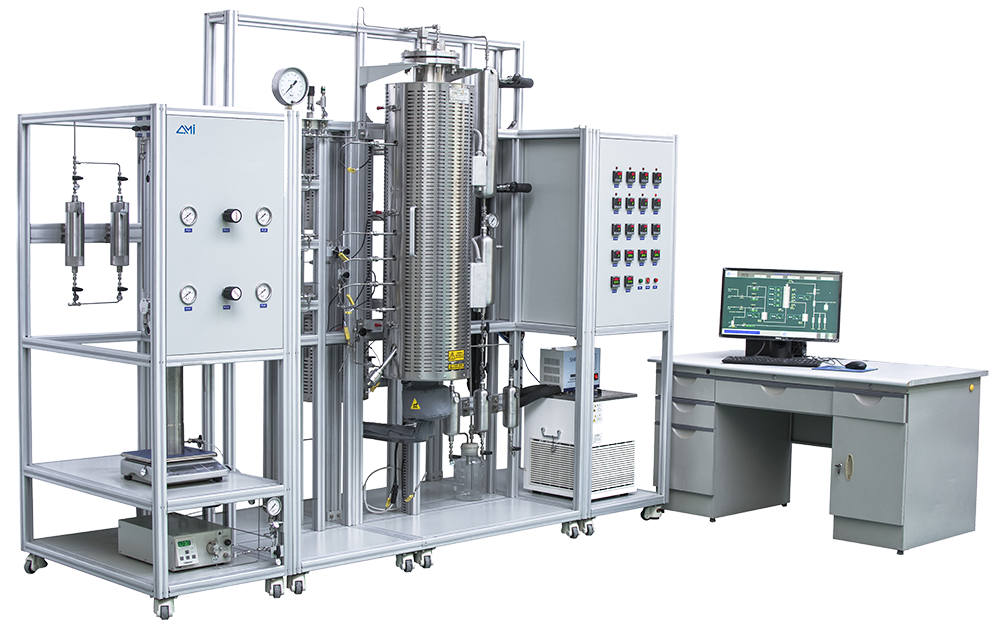

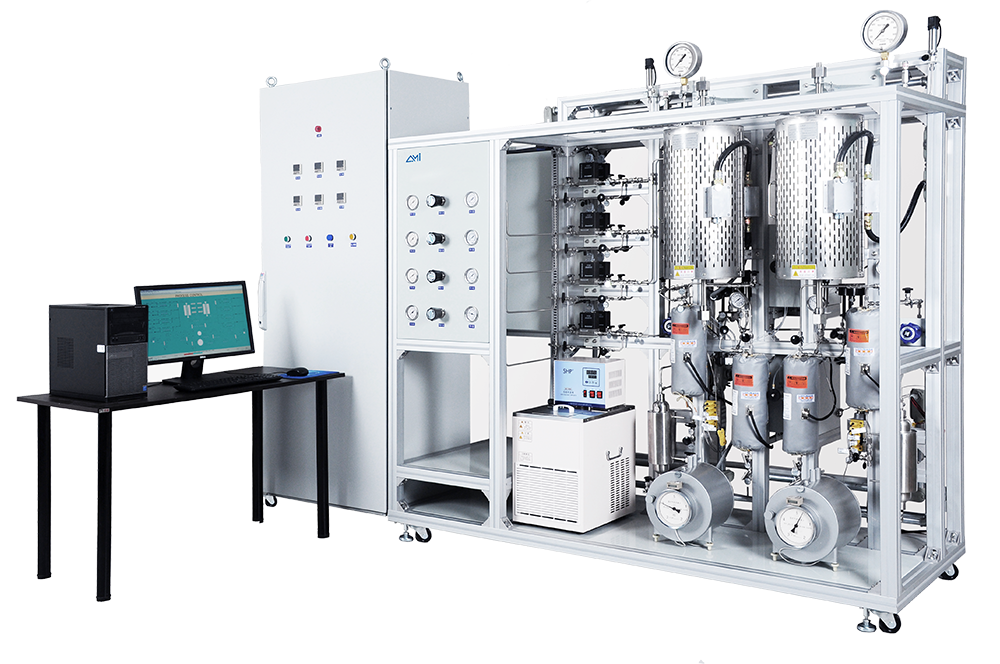

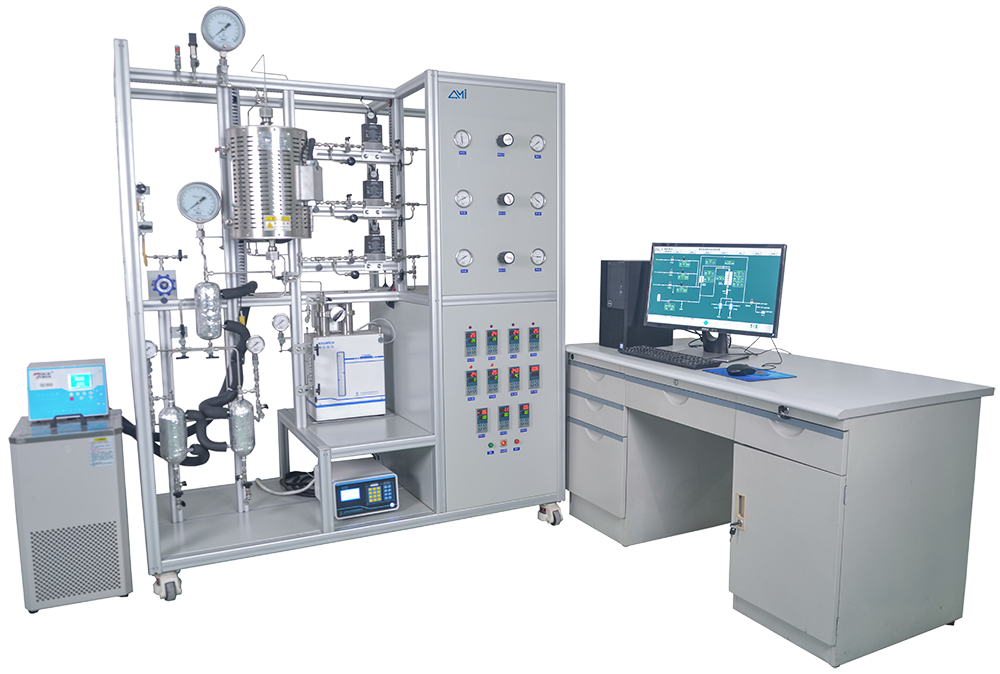

- The BenchCAT is built for researchers who need to process larger catalyst volumes or require custom reactor configurations. Typically designed as floor-standing systems or specialized setups, BenchCAT units are ideal for advanced catalysis studies, pilot-scale testing, or any application that goes beyond standard fixed-bed reactor capabilities.

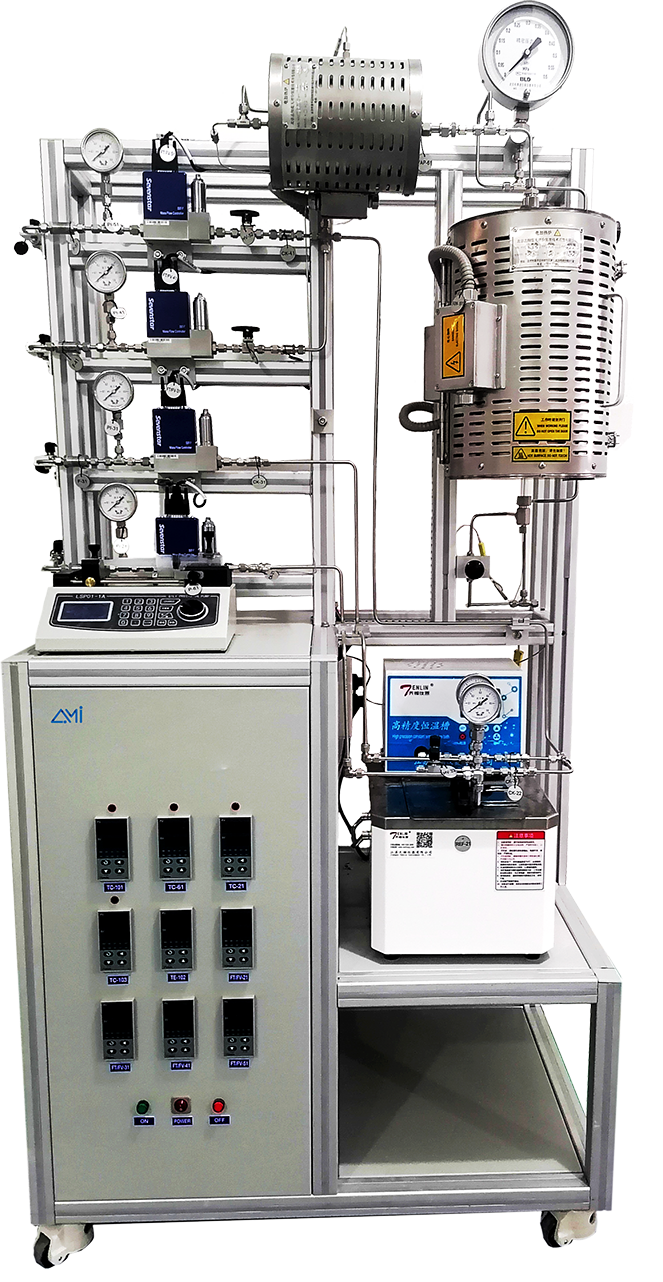

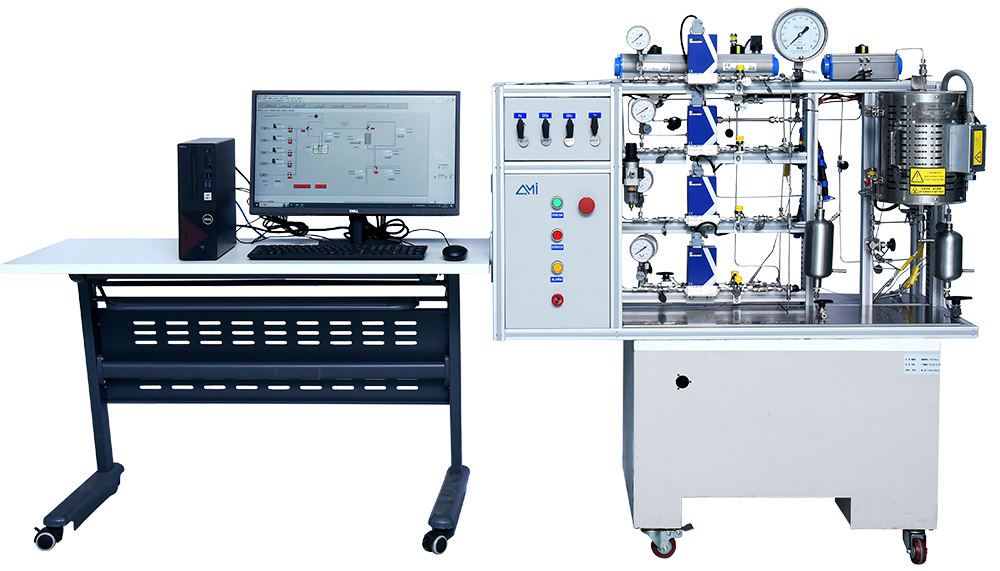

- By comparison, the μBenchCAT series consists of pre-engineered, benchtop systems that sit easily on a lab table or workbench. These compact units are optimized for fixed-bed catalytic experiments, with configurable options for gas and liquid feeds, as well as a range of temperature and pressure conditions. The microBenchCAT offers a spaceefficient and cost-effective solution for routine testing and academic research.

- Choose the BenchCAT when your research demands greater scale, flexibility, or custom design beyond what the microBenchCAT series offers. AMI will customize these instruments to meet your exact research needs today.

Advanced Measurement Instruments

Copyright © 2025 Advanced Measurement Instruments

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com