Magnetic suspension balance. Gravimetric sorption in real-world conditions. Dual-sample testing, up to 400°C.

● (4–60°C) temperature-controlled pycnometer, precise density.

● Integrated microbalance enables accurate weighing.

● PC-controlled automation records data automatically.

● Optional vacuum degassing to 10kPa.

The AMI DensiPyc Series delivers precise, repeatable true density measurement by combining advanced gas pycnometry with intelligent automation and flexible system configurations. Designed for both research and production environments, DensiPyc minimizes operator dependence while ensuring reliable, traceable results.

By integrating key measurement and control functions directly into the instrument, DensiPyc improves workflow efficiency, reduces potential error sources, and increases confidence in every reported value. All models comply with ISO 12154 for gas displacement density measurement using helium or nitrogen.

The AMI DensiPyc Series stands apart from traditional gas pycnometers by combining smart automation, flexible configurations, and precision features that enhance both productivity and data quality.

• Automated Sample Chamber Sealing

The DensiPyc uses an automated mechanical sealing system that applies consistent sealing force and positioning for every measurement. This eliminates variability introduced by manual tightening and improves repeatability across users and test runs.

• Intelligent Reference Volume Management

Multiple internal reference volumes are integrated into the system. During analysis, the software automatically selects the optimal reference configuration based on the installed sample cell, minimizing dead volume effects and improving volumetric accuracy across different sample sizes.

• Optional In-Situ Automatic Weighing (B Models)

Select models feature an integrated microbalance that allows samples to be weighed directly inside the instrument. This eliminates external weighing steps, reduces handling errors, improves traceability, and streamlines the workflow from loading through final reporting.

• Temperature-Control Options (TC models)

For samples that are temperature-sensitive, the TC (Temperature Control) models offer precise thermal regulation from 4°C to 60°C via an integrated Peltier module. This ensures consistent conditions and repeatable results, even for challenging materials.

• Vacuum Degassing Options (V models)

For materials that require pre-treatment prior to analysis, the V (Vacuum Degassing) models provide integrated vacuum conditioning to remove residual gases or moisture from the sample. The system supports vacuum levels down to 10 kPa, improving sample consistency and measurement repeatability, while maintaining a streamlined, single-instrument workflow.

The DensiPyc Series is available in multiple configurations to match laboratory workflows and application requirements:

• DensiPyc 1000: Designed for standard quality control and routine true density measurements where manual weighing, ambient temperature operation, and simple sample preparation are sufficient.

• DensiPyc 1000 TC: Adds active temperature control (TC) for materials sensitive to environmental fluctuations, improving measurement stability and repeatability under varying laboratory conditions.

• DensiPyc 1000 B: Incorporates an integrated balance (B) for automated sample weighing, reducing manual handling and improving throughput in quality control and routine testing environments.

• DensiPyc 1000 V: Includes integrated vacuum degassing (V) for sample pre-treatment prior to analysis, supporting materials that require moisture or gas removal.

Combined Configurations – Temperature control (TC), integrated weighing (B), and vacuum degassing (V) may be specified individually or in any combination, allowing the DensiPyc 1000 to be configured to match specific laboratory workflows and application requirements. The DensiPyc 1000-TCBV represents the most complete configuration, combining all three options.

The AMI DensiPyc Series is engineered to deliver accurate and repeatable true density measurements across a wide range of industries and material types. Its versatility, automation, and precision make it an ideal tool for laboratories focused on quality control, product development, and research.

• Additive manufacturing (AM) powders

Ensure consistency in metal and polymer powders used for 3D printing, improving part integrity and quality.

• Catalysts

Measure true (skeletal) density of catalyst powders, pellets, and supports to support porosity calculations, formulation consistency, and quality control.

• Pharmaceuticals and nutraceuticals

Measure true density of active ingredients and excipients for better formulation control and tablet uniformity.

• Polymers, ceramics, and refractories

Analyze structural materials for performance under thermal, chemical, and mechanical stress.

• Cement and construction materials

Support materials development and quality assurance by tracking density changes linked to composition and performance.

From R&D to production environments, the DensiPyc Series provides the data and confidence

needed to make informed decisions in material science and process optimization.

The DensiPyc Series is designed not only for speed and convenience, but for laboratory-grade precision and data consistency. Its software environment combines guided workflows with automated data handling to minimize operator dependence while maintaining rigorous measurement control. This approach ensures reliable results in both routine quality control and advanced material characterization applications.

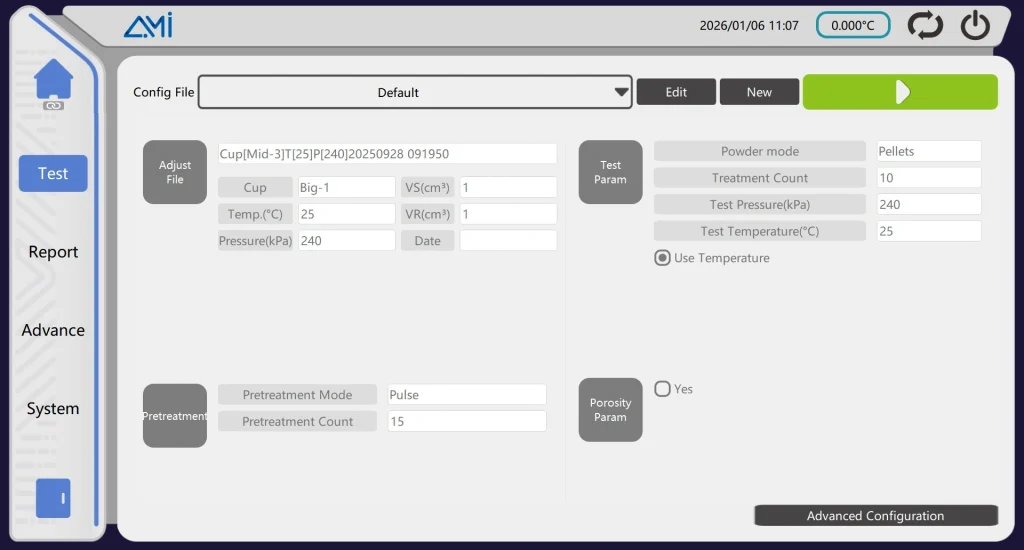

Fast Test Mode

The DensiPyc software includes predefined test routines that allow standardized measurements to be initiated with minimal parameter setup. This simplifies operation for routine quality control while maintaining consistent test conditions across operators and laboratories, making the system well suited for high-throughput environments.

Intuitive Data Processing & Reporting

Automated data processing and one-click report generation streamline result evaluation and documentation. Measurement data can be exported in common file formats, while built-in tools enable easy comparison of historical and batch-to-batch results to support process monitoring and trend analysis.

| Parameter | Specification |

|---|---|

| Test Gas | Helium, Nitrogen, Inert Gases |

| Gas Delivery Method | Pulsed injection or Flow with pressure equilibration, vacuum as option, Fine powder handling methods (Powder Guard Mode) |

| Repeatability |

|

| Accuracy |

|

| Sample Cell Volumes | 100 mL, 35 mL, and 10 mL (standard) Optional: smaller sample cups |

| Integrated Balance (model dependent) | Up to 500g; 0.001g balance resolution |

| Pressure Parameters |

|

| Data Output | PDF, TXT, Excel, connected via Ethernet |

| Temperature Range (model dependent) | 4–60°C (TC models only; Peltier-controlled); Stability: +/- 0.01°C; Accuracy: 0.002°C |

| Integrated Vacuum (model dependent) | Sample pretreatment via vacuum degassing (integrated pump) to 10kPa |

| Operating Environment | 15–35°C, 10–90% RH, non-condensing |

| Power | 100–240 VAC, 50/60 Hz, 120W (standard), 320W (temperature control) |

| Footprint (W × D × H) | 465 × 350 × 370 mm / 18 × 14 × 15 in |

| Weight | Approx. 10 kg / 22lbs |

| Applicable Standards | Measurements are performed using gas displacement principles in accordance with: ISO 12154; ASTM D4892, B923, C604, C830; DIN 66137; USP <699> |

| Sample Preparation Accessories (option) |

|