Magnetic suspension balance. Gravimetric sorption in real-world conditions. Dual-sample testing, up to 400°C.

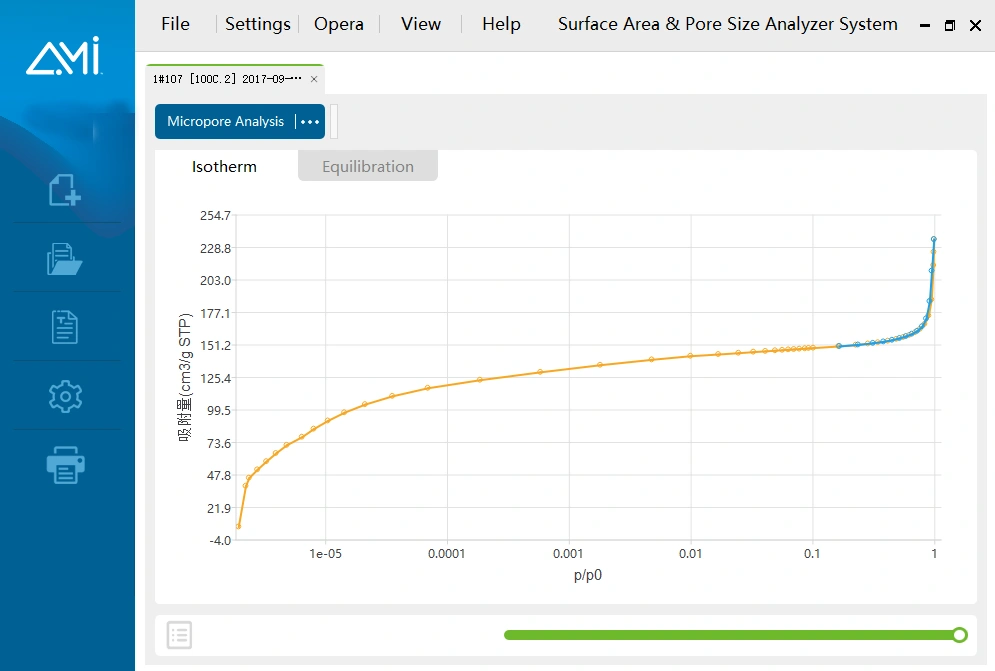

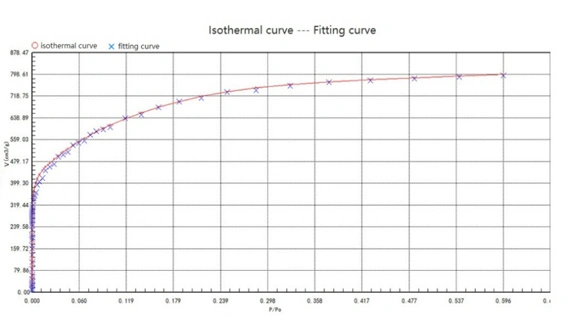

The AMI-Micro 100 Series is a high-precision physisorption instrument designed for the accurate determination of specific surface area and pore size distribution in a wide range of materials. The series is available in three distinct models—A, B, and C—each offering specialized capabilities to accommodate various analytical requirements (refer to the specification table for further details).

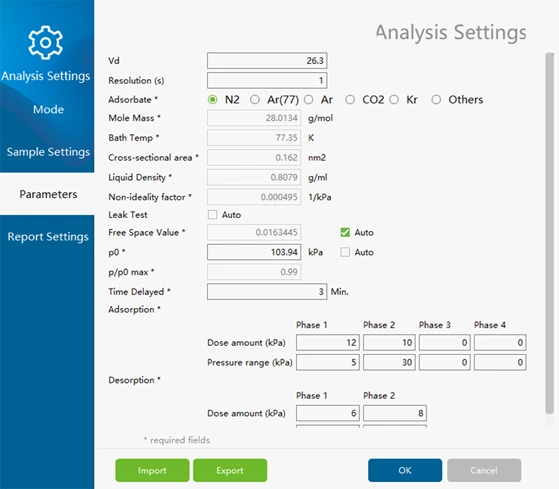

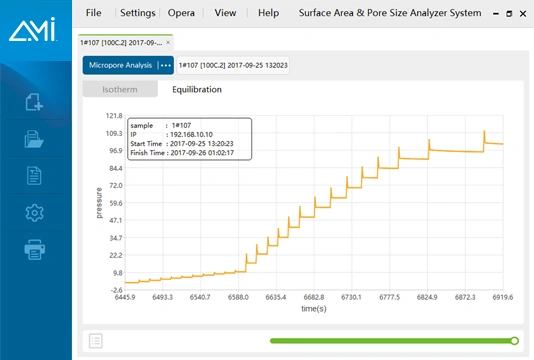

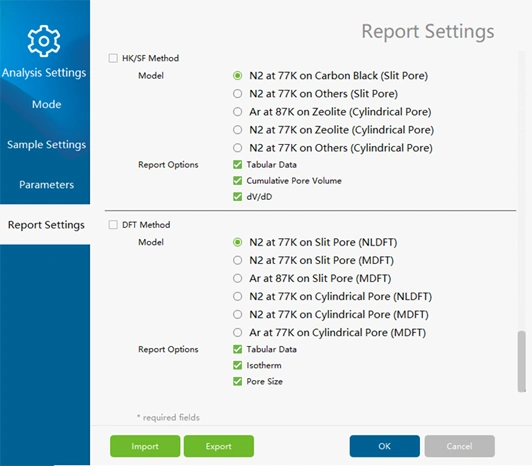

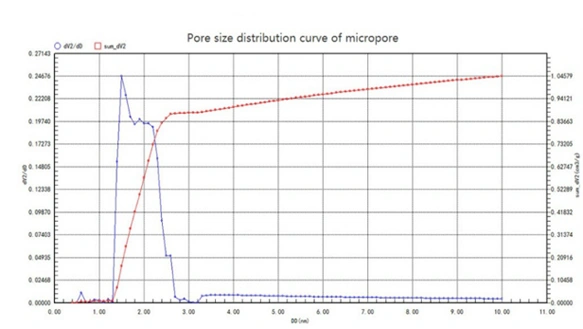

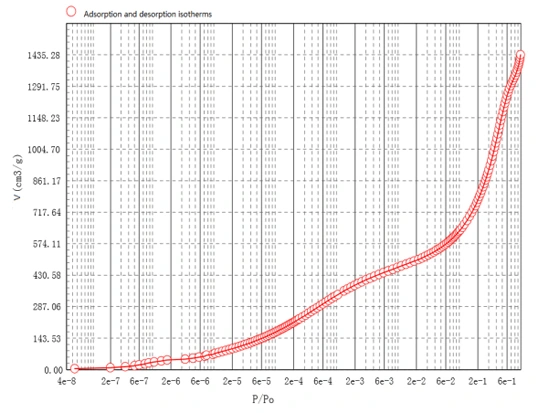

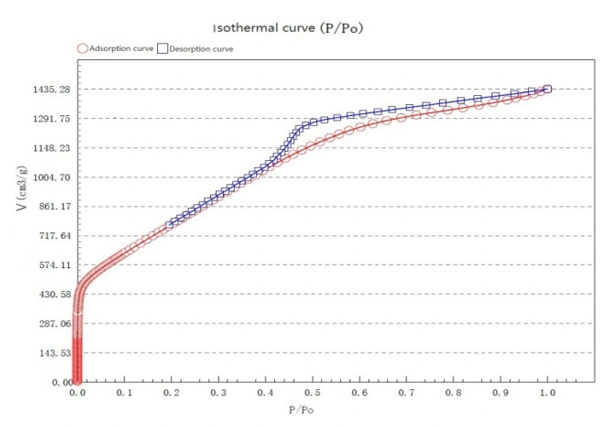

The Micro 100 C model is equipped with high-sensitivity 1 torr pressure transducers (with an optional 0.1 torr configuration) and a turbo molecular pump achieving an ultimate pressure of 10⁻⁸ Pa, ensuring exceptional accuracy in the characterization of microporous structures. Furthermore, all analysis stations incorporate in-situ sample preparation, effectively minimizing contamination and enhancing measurement reliability.

Engineered for advanced materials research, the AMI-Micro 100 Series is particularly well-suited for the characterization of microporous materials, including metal-organic frameworks (MOFs), molecular sieves, catalysts, activated carbon, and other porous substances, providing precise and reproducible gas adsorption analysis.