Differential Scanning Calorimetry (DSC) is a fundamental technique used to study phase transitions, heat capacity, and thermal stability in materials […]

Introduction

Differential Scanning Calorimetry (DSC) is a fundamental technique used to study phase transitions, heat capacity, and thermal stability in materials. However, most conventional DSC systems are limited to temperatures below 700 °C. For advanced materials research—such as ceramics, metals, high-performance polymers, and oxides—thermal transitions often occur well above 1000 °C.

To meet this need, Advanced Measurement Instruments (AMI) has developed the DSC 1200 and DSC 1500—two high-temperature DSC systems built on a proven STA platform. This application note outlines the advantages of using a hang-down STA-derived architecture for DSC-only measurements and highlights the capabilities of both models for demanding thermal analysis.

Why Use an STA Platform for High-Temperature DSC?

The STA platform is typically used for simultaneous TGA/DSC measurements, but when adapted for DSC only functionality, it offers significant advantages:

Elimination of the microbalance simplifies the system, reduces thermal interference, and focuses entirely on calorimetric precision.

Hang-down geometry ensures superior thermal isolation from the furnace environment, enhancing signal stability and minimizing baseline drift. A vertical lift furnace ensures consistent sample positioning and safe high-temperature operation.

The use of high-purity platinum components and precision-machined sensor assemblies ensures consistent sensitivity and durability at elevated temperatures.

This architecture allows AMI’s high-temperature DSC systems to achieve the same thermal range and mechanical robustness of an STA, while offering the clarity and simplicity of a pure DSC system.

System Overview: AMI DSC 1200 / DSC 1500

AMI DSC 1200

Temperature Range: Ambient to 1200 °C

Heating Rate: 0.1 to 60 °C/min

AMI DSC 1500

Temperature Range: Ambient to 1500 °C

Heating Rate: 0.1 to 60 °C/min

Shared Features:

Calorimetric Accuracy: ±1% (with certified standards)

Thermocouples: Type R (sample and reference), cold-junction compensated

DSC Sensor: Platinum-rhodium with integrated sample/reference cups

Atmosphere Control: Static or Dynamic

Furnace Cooling: Water-cooled with integrated safety interlocks

Sensor Access: Tool-free access for pan replacement and calibration

Software: InfinityPro for instrument control, method development, calibration, and real-time data

visualization

Communications: RS-232 or USB interface

Safety: Factory-limited lift range, over-temperature protection, and water flow alarm

Applications

AMI’s high-temperature DSC systems are ideal for advanced thermal characterization in materials that

require extended temperature range and stability. Application areas include:

Ceramics and oxides: Phase transitions, sintering behavior, and glass crystallization

Refractory materials: Fusion and degradation temperatures

Metallic alloys: Solid-state transformations and oxidation

High-performance polymers: Thermal degradation and glass transition above 600 °C

Battery materials: Decomposition and thermal runaway characterization

The high sensitivity and stable baseline make these instruments suitable for both large enthalpic events and subtle thermal transitions.

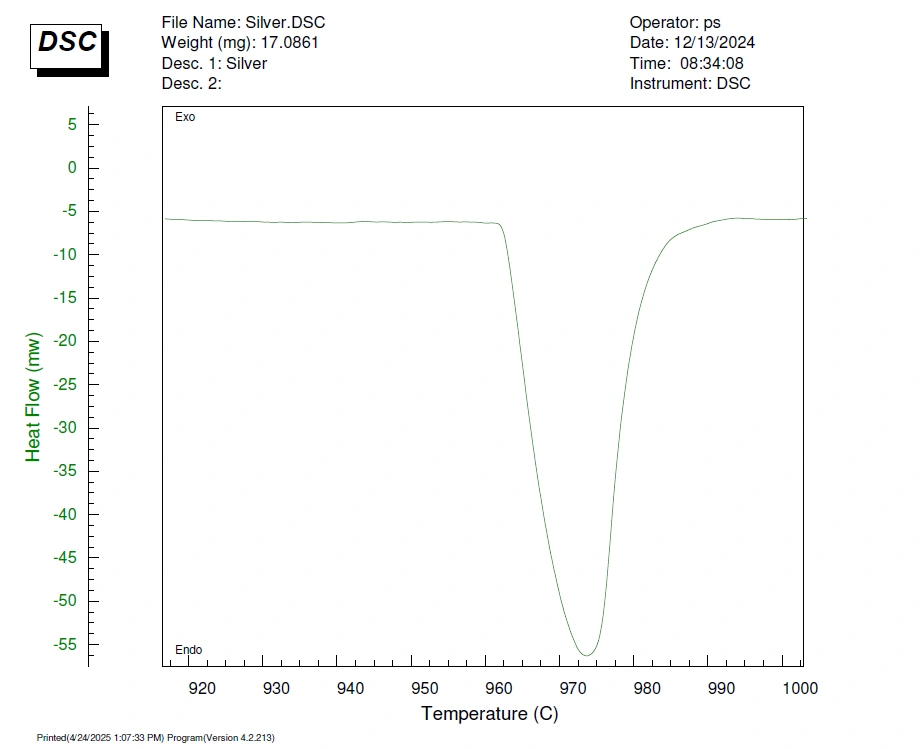

Figure 1. DSC curve of high-purity silver (Ag) showing a sharp endothermic peak at 961.8 °C corresponding to its melting point.

Silver offers an excellent benchmark for high-temperature DSC calibration due to its well-defined melting point and heat of fusion. The sharp endothermic peak at 961.8 °C illustrates the system’s sensitivity and temperature accuracy. The flat baseline and low noise level emphasize the DSC’s thermal stability and precision over extended high-temperature ramps.

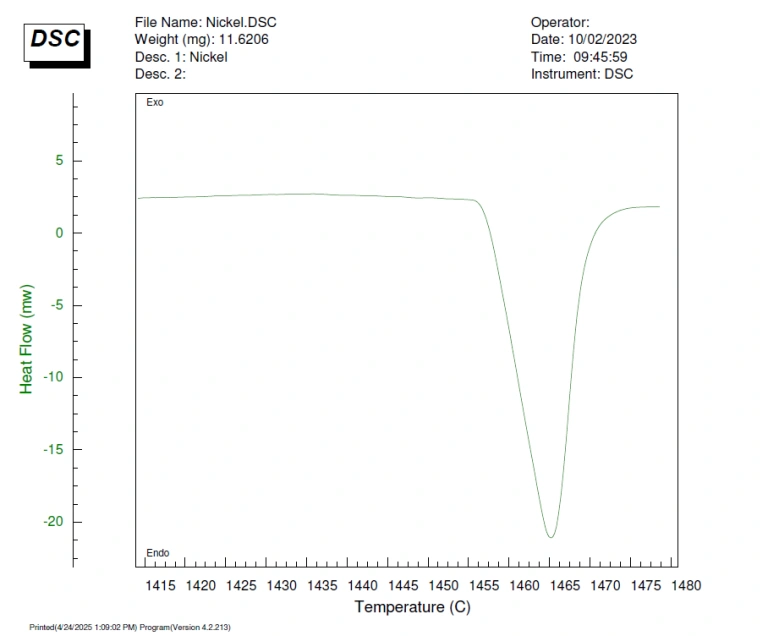

Figure 2. DSC curve of high-purity nickel (Ni) demonstrating a strong endothermic melting peak at approximately 1455 °C

This curve demonstrates the DSC system’s capability to operate at elevated temperatures with excellent resolution. The melting of nickel, a refractory metal, is clearly resolved even near the upper range of the instrument’s performance. The signal clarity underscores the robustness of the sensor design and heating system for demanding thermal analysis applications.

Advantages of a High-Temperature Hang-Down DSC

| Features and Benefits | |

|---|---|

| Feature | Benefit |

| Hang-down sensor geometry | Enhances thermal isolation and improves baseline stability by minimizing thermal gradients and interference from furnace heat. |

| STA-derived furnace | Provides proven temperature stability, uniform heating, and controlled ramping to 1200 °C or 1500 °C. |

| Balance-free configuration | Simplifies the system architecture and ensures pure calorimetric signal without mass-related drift or noise. |

| Integrated gas control | Supports inert, oxidizing, or reactive environments. |

| Water cooling with safety interlock | Enables safe high-temperature operation with automatic shutdown protection. |

System Configuration and Installation

Each AMI DSC system is shipped with:

Main module with vertically lifting furnace

Dedicated DSC sensor and standard sample/reference pans

Gas inlets

InfinityPro software license

Start-up accessory kit: sample holders, tools, thermocouples, communications cable

Remote installation support, unlimited virtual training, and application support

Conclusion

The AMI DSC 1200 and DSC 1500 systems provide powerful, stable, and high-precision platforms for thermal analysis beyond the limits of conventional DSC. By leveraging the mechanical strength and thermal performance of STA architecture—without the complexity of a balance—AMI delivers research-grade solutions for laboratories working at the forefront of materials science.

Differential Scanning Calorimetry (DSC) is a fundamental technique used to study phase transitions, heat capacity, and thermal stability in materials […]