In thermogravimetric analysis (TGA), one of the primary objectives is to separate and characterize individual components within a sample based on their thermal […]

In thermogravimetric analysis (TGA), one of the primary objectives is to separate and characterize individual components within a sample based on their thermal […]

Overview

In thermogravimetric analysis (TGA), one of the primary objectives is to separate and characterize individual components within a sample based on their thermal decomposition behavior. However, when multiple thermal events occur in close temperature proximity, overlapping mass-loss signals can reduce resolution and limit interpretability.

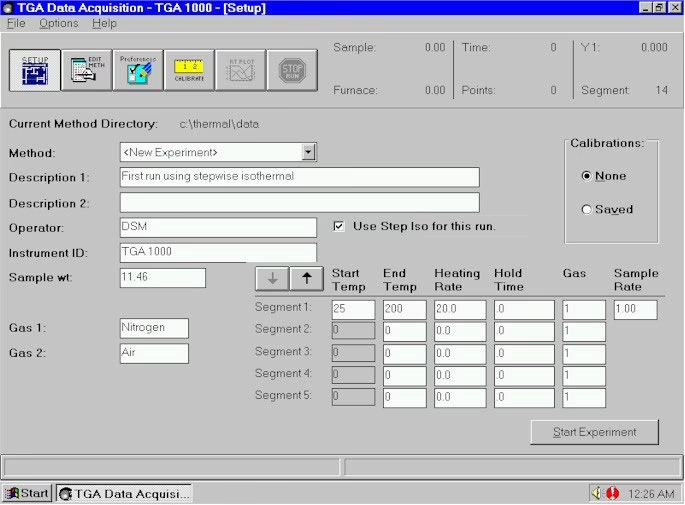

Factors such as sample mass, purge gas, and heating rate affect this resolution, with heating rate being the most impactful. To address these limitations, AMI has integrated a Step Isothermal function into the InfinityPro software platform for its TGA systems.

What Is Step Isothermal?

Step Isothermal TGA introduces dynamic control over heating conditions by allowing the system to:

•Heat the sample at a defined linear rate

•Monitor real-time derivative weight loss (%/min)

•Automatically switch to an isothermal hold once a predefined Iso Start Threshold isexceeded

•Resume the temperature ramp once the Ramp Resume Threshold is reached

This smart switching improves separation of closely spaced decomposition steps that may otherwise appear merged during traditional linear ramping.

Figure1: TGA software setup window with Step Isothermal option enabled

How It Works

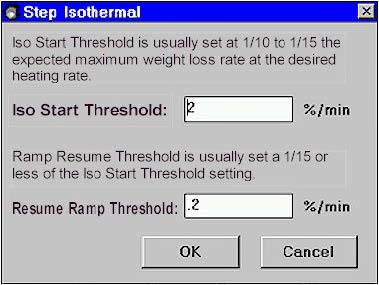

• The Iso Start Threshold defines the rate of weight loss at which the system will enter an isothermal hold. This is typically set at ~1/10th to 1/15th of the expected peak weight loss rate.

• The Ramp Resume Threshold determines when the system will exit the isothermal condition and resume ramping. It is typically ~1/15th or less of the Iso Start Threshold.

This cycle continues throughout the experiment, enabling adaptive thermal profiling based on the material’s real-time behavior.

Figure 2: Step Isothermal method setup dialog showing threshold parameters.

Case Study Example

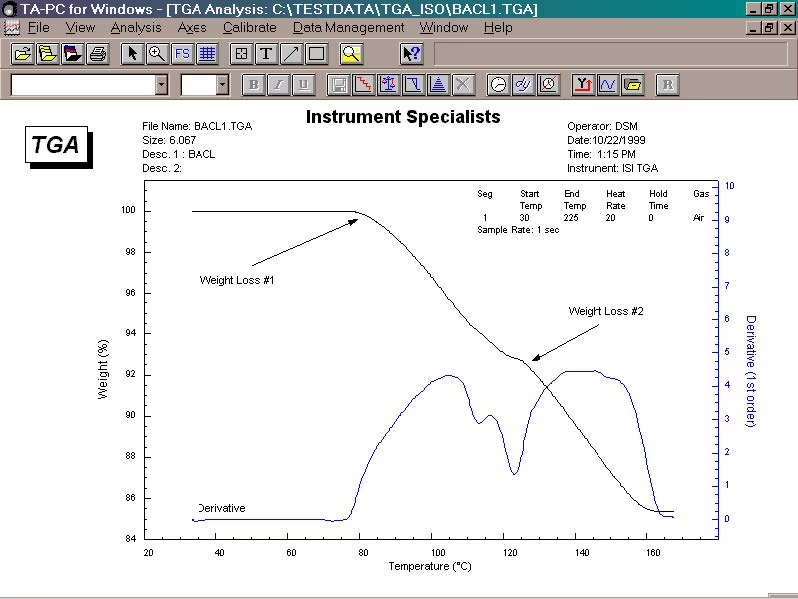

A conventional TGA run on Barium Chloride at 20 °C/min reveals two overlapping mass-loss events—one at approximately 80 °C and another around 110 °C. These transitions appear as a single broadened event in standard TGA.

Figure 3: Conventional TGA curve for Barium Chloride showing overlapping events.

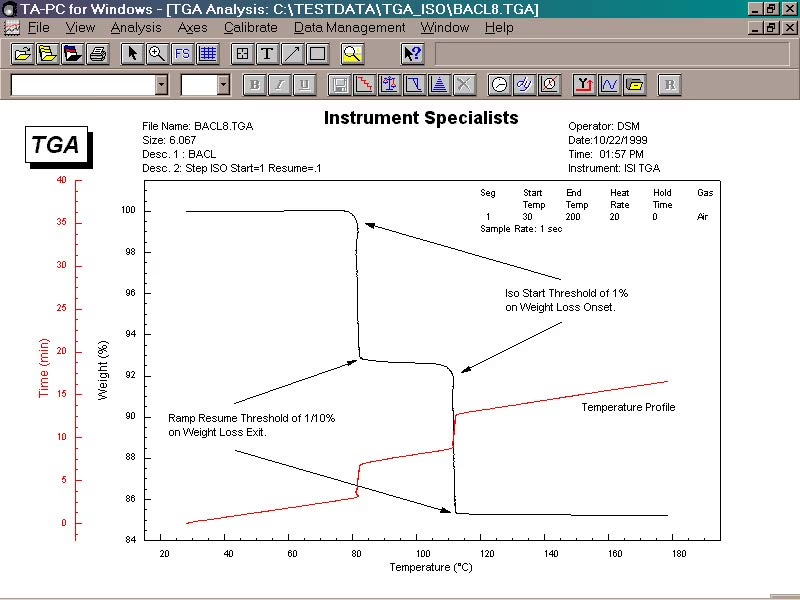

Using Step Isothermal, the same material yields two distinct weight-loss steps, allowing accurate resolution of each component’s thermal behavior. The system automatically pauses heating during high-rate decomposition, improving event separation.

Figure 4: Improved separation using Step Isothermal mode on the same material.

Key Benefits

• Enhanced separation of overlapping decomposition or reaction events.

• Automated transition control based on actual weight loss.

• No need for complex scripting or multiple trial runs.

• Especially useful for polymers, composites, hydrates, and materials with closely spaced transitions.

Conclusion

Step Isothermal TGA, standard on all AMI TGA instruments, enables high-resolution thermal analysis for complex materials by combining real-time mass-loss monitoring with intelligent temperature control. This feature adds analytical power and flexibility while remaining fully accessible through AMI’s intuitive InfinityPro interface.

In thermogravimetric analysis (TGA), one of the primary objectives is to separate and characterize individual components within a sample based on their thermal […]