Advanced Measurement Instruments

Copyright © 2025 Advanced Measurement Instruments

Research Background

Shape Memory Alloy (SMA) is a metallic material composed of more than two metal elements that exhibits a shape memory effect—the ability to return to a pre-set shape after deformation when heated. This unique property results from a thermoelastic martensitic phase transformation and its reversibility.

Martensitic transformation is a non-diffusion solid-state phase change, characterized by atomic movement in a cooperative but localized way. It forms a metastable phase via twinning without altering the alloy’s chemical composition. SMAs are commonly categorized into NiTi-based, Cu-based, and Fe-based alloys [1]. Among these, NiTi-based alloys are the most commercially successful due to their superior shape recovery, superelasticity, corrosion resistance, and biocompatibility [2].

In NiTi alloys, the high-temperature phase is austenite (B2 structure), and the low-temperature phase is martensite (B19’ structure). The transformation is reversible and temperature-dependent:

NiTi alloys are usually fixed into a preset shape at high temperature (austenitic phase), then cooled below Ms to become soft and deformable. Upon reheating above Af, the alloy returns to its original shape. Therefore, accurately measuring the phase transformation temperatures (Ms, Mf, As, Af) is essential.

Why Use DSC for NiTi Phase Measurement

Due to the limitations of chemical composition analysis for NiTi (e.g., insufficient accuracy to predict transition temperatures), differential scanning calorimetry (DSC) is the preferred method for determining phase transformation behavior in samples with known thermal processing history.

DSC measures the difference in heat flow between a sample and an inert reference during controlled heating and cooling. The technique detects endothermic and exothermic events, corresponding to the energy changes during phase transitions.

Experimental Method

In this paper, the DSC 600 differential scanning calorimeter from AMI was used for testing NiTi-based SMA samples provided by our partner. The sample shapes are shown as follows:

Figure 1 Ni-Ti-based Shape Memory Alloy

Sample Preparation

The sample was cut to match the crucible’s inner diameter and placed inside a solid crucible. It was then pressed flat to ensure optimal contact between the sample and the crucible wall.

Test Conditions:

Testing Procedure:

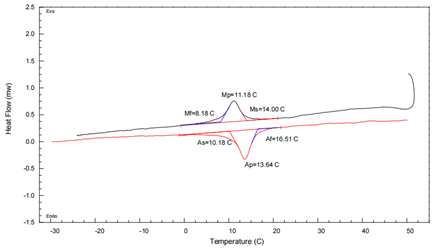

Figure 2 DSC Curve of Ni-Ti-based Shape

Results and Discussion

As shown in Figure 2, the cooling curve (black) shows an exothermic peak corresponding to the austenite-to-martensite transformation in the NiTi alloy.

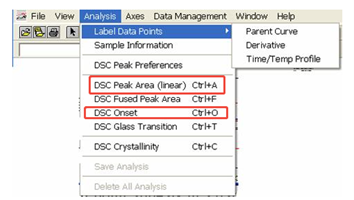

Phase transformation temperatures were determined using the tangent method, as illustrated in Figure 3, via the DSC Peak Area and DSC Onset functions provided by the software.

Martensitic Transformation (Cooling)

An endothermic peak is observed on the heating curve (red), indicating the reverse transformation from martensite to austenite:

Austenitic Transformation (Heating)

Figure 3: Analysis Functions of DSC 600 Software

These results demonstrate the precise sensitivity of DSC in detecting reversible phase changes in NiTi-based shape memory alloys.

Conclusion

This study confirms that DSC (DSC 600 by AMI) is the most direct and accurate method for identifying phase transition behavior in NiTi SMAs. The results provide reliable determination of Ms, Mf, As, and Af—critical values for SMA performance in devices ranging from medical stents to aerospace actuators.

References

[1] Wang Shuo, Wang Yuanhao. Overview of research progress on shape memory alloys [J]. Scientific and Technological Innovation. 2020(21): 39-40

[2] Mei Hai. Study on martensitic transformation and shape memory effect of NiTi shape memory alloy [D]. Harbin Engineering University, 2023